Method for Improving Edge Roughness of Tungsten Silicide Double Gate of Self-Aligned Contact Hole

A self-aligned contact hole and edge roughness technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of large tungsten silicide grains and inclined morphology, and achieve improved edge roughness, Avoid etch residue, the effect of smooth gate sidewall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

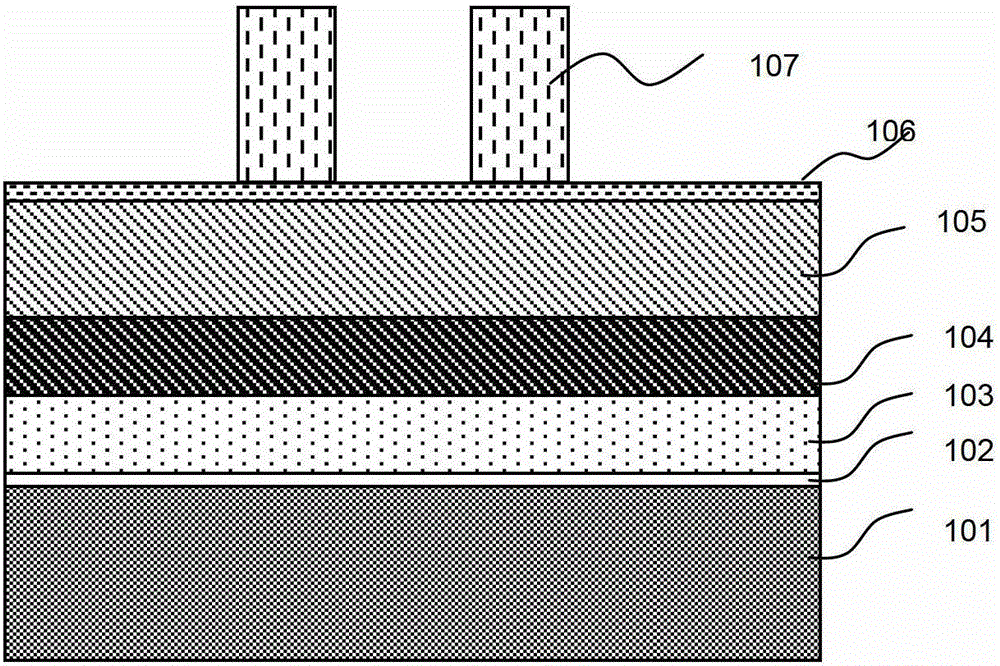

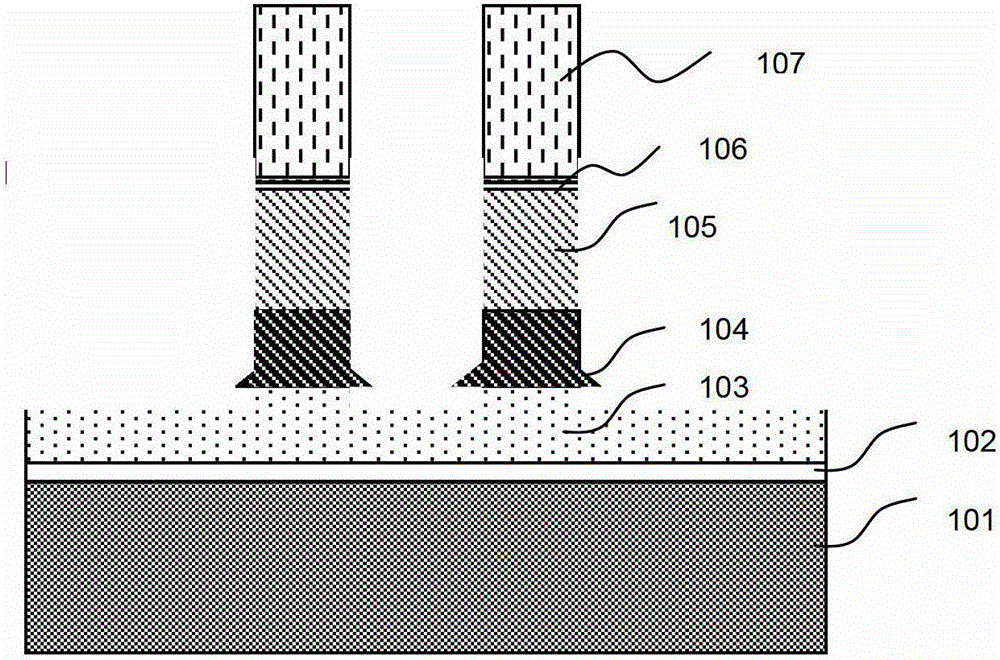

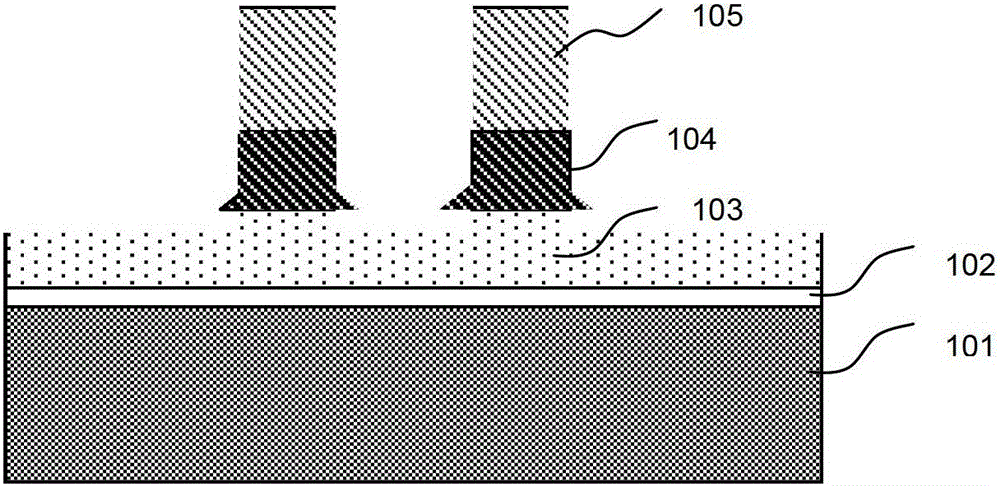

[0030] figure 1 Fig. 5 has shown processing steps of the present invention, and the inventive method mainly comprises the following steps:

[0031] 1. If figure 1 As shown, a gate dielectric layer 102 (a gate oxide film is used in this embodiment) with a thickness of 20-40 angstroms is grown on a silicon substrate 101 by thermal oxidation; on the gate dielectric layer, a CVD method is used to deposit A layer of polysilicon 103 of about 700-800 angstroms, polysilicon deposition temperature is selected at 500-600 degrees Celsius, CVD or PVD is used to grow tungsten silicide (WSix) 104 on the polysilicon 103, the thickness is 600-750 angstroms, and the process temperature of CVD and PVD can not exceed 600 degrees Celsius, so as to avoid the formation of silicon clusters in WSix; on the tungsten silicide 104, use PECVD or CVD process to deposi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com