Apparatus and process for nitration selectivity flexibility enabled by azeotropic distillation

Azeotropic distillation, water-based technology, applied in chemical instruments and methods, preparation of nitro compounds, preparation of organic compounds, etc., can solve problems such as high cost, acid loss of overhead distillate, energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

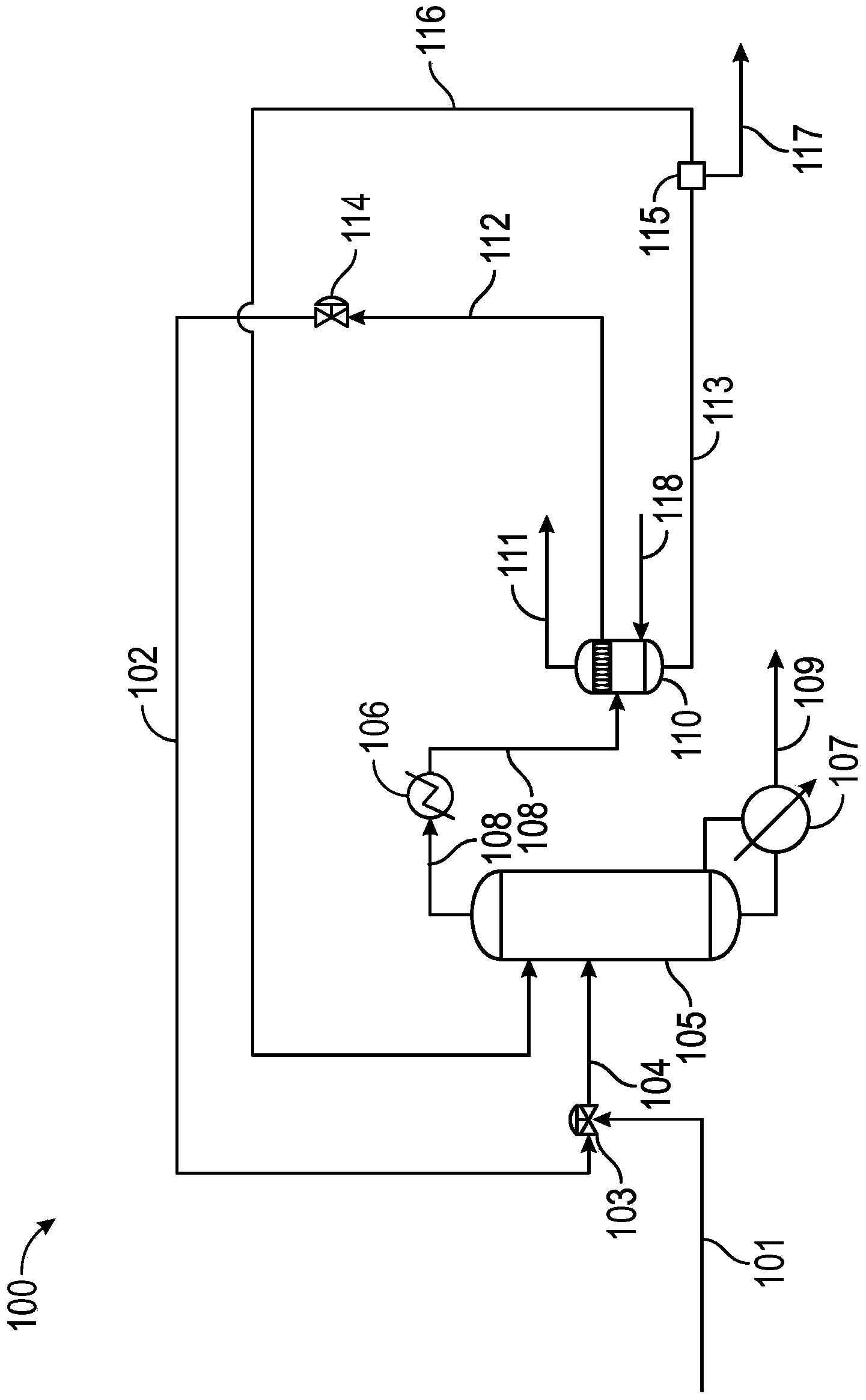

[0049] Example 1:Heterogeneous azeotropic distillation scheme for the concentration of acetic acid using isopropyl acetate

[0050] This example illustrates the use of isopropyl acetate as an entrainer. The Heterogeneous Azeotropic Distillation (HAD) column is designed to yield acetic acid product of desired purity in the bottoms, while simultaneously yielding an isopropyl acetate / water azeotrope as overhead. The overhead stream forms two liquid phases upon condensation and decantation - an organic phase and an aqueous phase. The organic phase mainly contained isopropyl acetate, while the aqueous phase mainly contained water (Acid Free Aqueous Stream (AFAS)). The entire organic phase is refluxed back to the HAD column to provide enough isopropyl acetate to act as an entrainer. It is then mixed with the feed stream and co-fed to the HAD column. The aqueous phase is withdrawn from the system for further processing or discharge. If the organic reflux does not meet the colum...

Embodiment 2

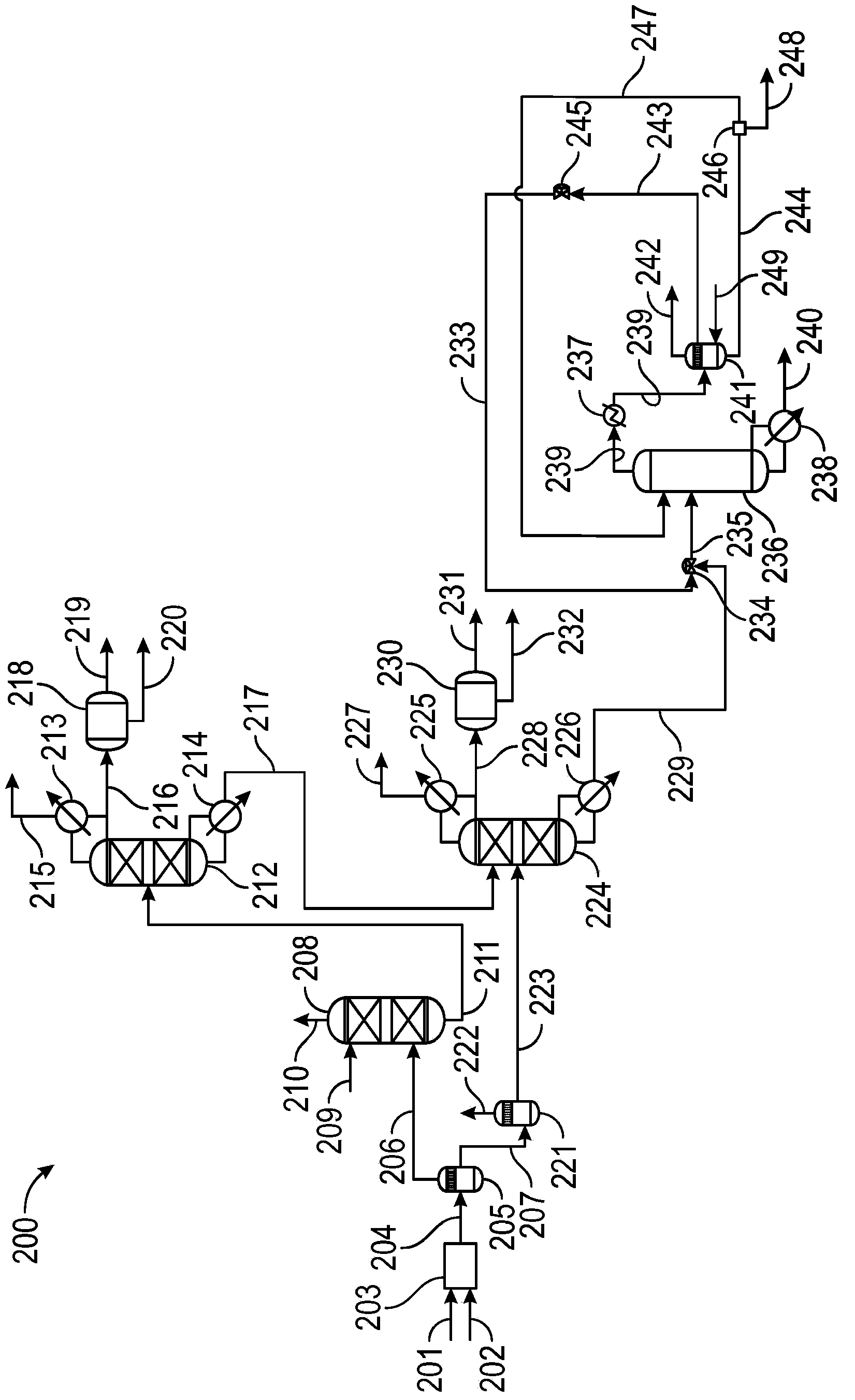

[0058] Example 2: Heterogeneous azeotropic distillation scheme for the concentration of acetic acid using n-butyl acetate

[0059] This example illustrates the use of n-butyl acetate as the entrainer. The HAD column is designed to yield acetic acid product of the desired purity in the bottoms while simultaneously yielding an n-butyl acetate / water azeotrope as overhead. The overhead stream forms two liquid phases upon condensation and decantation - an organic phase and an aqueous phase. The organic phase mainly contained n-butyl acetate, while the aqueous phase mainly contained water (Acid Free Aqueous Stream (AFAS)). The entire organic phase is refluxed back to the HAD column to provide enough n-butyl acetate to act as an entrainer. It is then mixed with the feed stream and co-fed to the HAD column. The aqueous phase is withdrawn from the system for further processing or discharge. If the organic reflux does not meet the column specifications, a portion of the aqueous ph...

Embodiment 3

[0064] Example 3: Heterogeneous azeotropic distillation scheme for the concentration of acetic acid using isobutyl acetate

[0065] This example illustrates the use of isobutyl acetate as an entrainer. The HAD column is designed to yield acetic acid product of the desired purity in the bottoms while simultaneously yielding the isobutyl acetate / water azeotrope as overhead. The overhead stream forms two liquid phases upon condensation and decantation - an organic phase and an aqueous phase. The organic phase mainly contained isobutyl acetate, while the aqueous phase mainly contained water (Acid Free Aqueous Stream (AFAS)). The entire organic phase is refluxed back to the drying column to provide enough isobutyl acetate to act as an entrainer. It is then mixed with the feed stream and co-fed to the HAD column. The aqueous phase is withdrawn from the system for further processing or discharge. If the organic reflux does not meet the column specifications, a portion of the aq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com