High wear-resistant silica molybdenum brick and its preparation method

A kind of silicon mulberry brick, high wear resistance technology, applied in the field of refractory materials, can solve the problem that the service life is only in the interval of half a year to one year, the fire resistance, wear resistance, corrosion resistance and thermal shock resistance are average, and the ability to resist the erosion of cement clinker. Weakness and other problems, to achieve the effect of compact structure, improved thermal shock resistance, high load soft temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

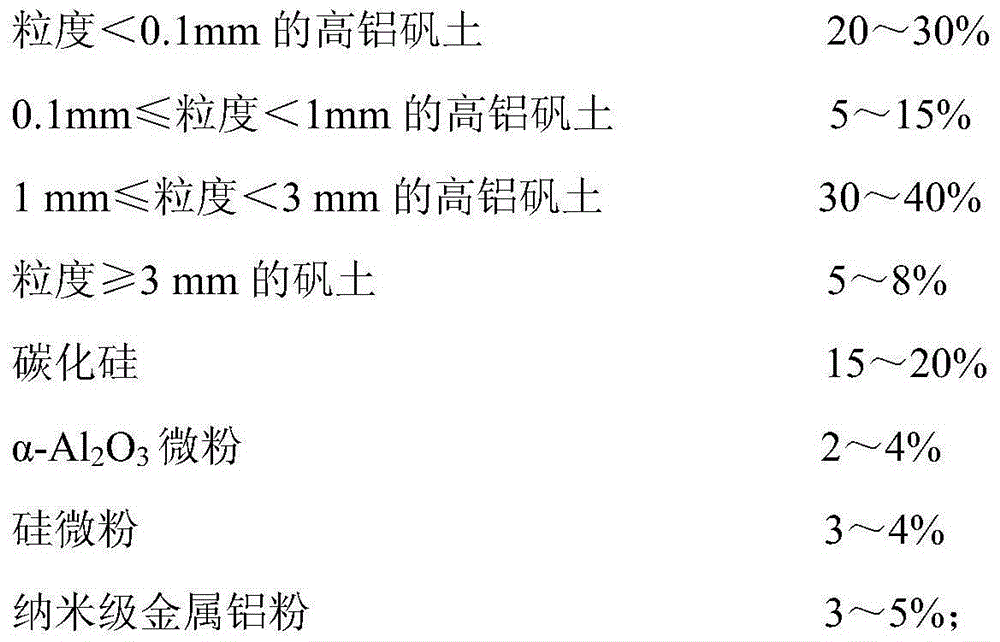

[0029] A high wear-resistant silica brick prepared from the following components in weight percentage:

[0030]

[0031]

[0032] Wherein, the high alumina bauxite is Al 2 o 3 Special grade high bauxite with a weight percentage of 89%; bauxite is Al 2 o 3 Special-grade alumina with a weight percentage of 86%; the main component of silicon carbide, SiC, has a content of 98%, a bulk density of 3.215g / cm3, and a particle size of ≤3mm; α-Al 2 o 3 The main component of micropowder is Al 2 o 3 The content of silicon dioxide is 99.0%, the bulk density is 3.99g / cm3, and the particle size is 2 content of 97%, specific surface area of 16m 2 / g, particle size <1μm, pH value 5.6.

[0033] The preparation method of high wear-resistant silica molybdenum brick comprises the following steps:

[0034] The first step, making mud: Weigh the above components according to the proportion, add pulp waste liquid with a total component weight of 6.0%, and mix and grind in a planetary m...

Embodiment 2

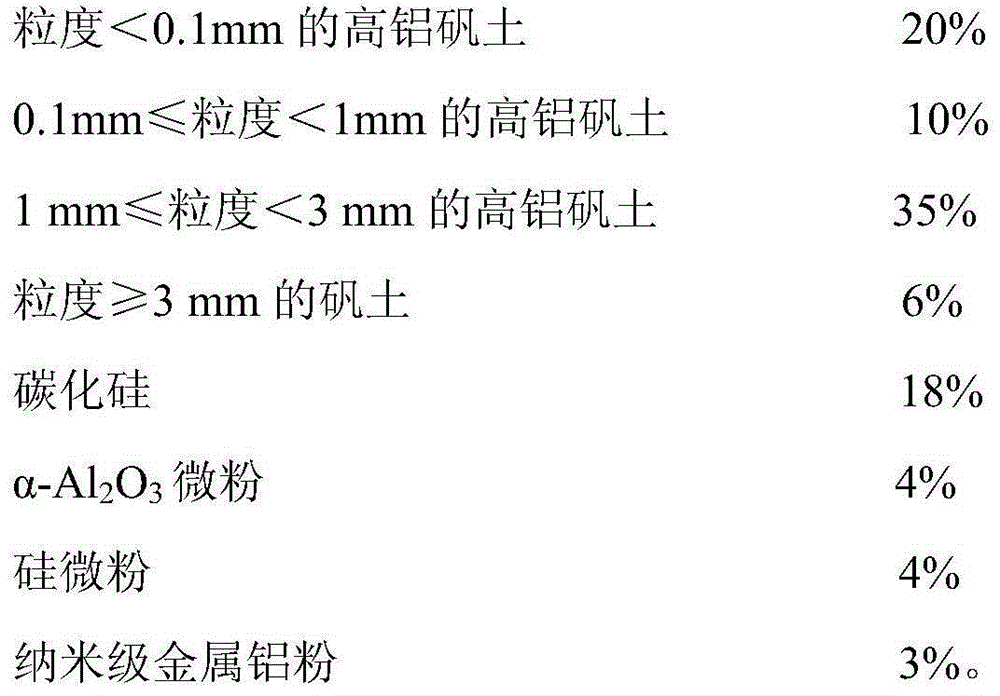

[0041] A high wear-resistant silica brick prepared from the following components in weight percentage:

[0042]

[0043]

[0044] Wherein, the high alumina bauxite is Al 2 o 3 Special grade high bauxite with 90% by weight; bauxite is Al 2 o 3 Special grade bauxite with a weight percentage of 87%; the main component of silicon carbide, SiC, with a content of 98%, a bulk density of 3.215g / cm3, and a particle size of ≤3mm; α-Al 2 o 3 The main component of micropowder is Al 2 o 3 The content of silicon dioxide is 99.3%, the bulk density is 3.98g / cm3, and the particle size is 2 content of 97%, specific surface area of 18m 2 / g, particle size <1μm, pH 6.3.

[0045] The preparation method of high wear-resistant silica molybdenum brick comprises the following steps:

[0046] The first step, making mud: weigh the above components according to the proportion, add pulp waste liquid with a total component weight of 5.0%, and mix and grind in a planetary mixer to make mud; ...

Embodiment 3

[0052] A high wear-resistant silica brick prepared from the following components in weight percentage:

[0053]

[0054] Wherein, the high alumina bauxite is Al 2 o 3 Special grade high bauxite with 92% by weight; bauxite is Al 2 o 3 Special-grade alumina with a weight percentage of 86%; the main component of silicon carbide, SiC, has a content of 98%, a bulk density of 3.215g / cm3, and a particle size of ≤3mm; α-Al 2 o 3 The main component of micropowder is Al 2 o 3 The content of silicon powder is 99.5%, the bulk density is 3.99g / cm3, and the particle size is less than 5μm; the main component of silicon micropowder is SiO 2 content of 97%, specific surface area of 26m 2 / g, particle size <1μm, pH value 7.5.

[0055] The preparation method of high wear-resistant silica molybdenum brick comprises the following steps:

[0056] The first step, making mud: weigh the above components according to the proportion, add pulp waste liquid with a total component weight of 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com