A preparation method of an efficient oil absorption material

An oil-absorbing material and high-efficiency technology, applied in the field of preparation of high-efficiency oil-absorbing materials, can solve the problems of synthetic resin purity, performance, application range and production process being difficult to control, poor lipophilicity of ester groups, and small molecular network structure. , to achieve the effect of large molecular network structure, enhanced corrosion resistance and strong lipophilic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1. Preparation of water phase

[0028] In parts by weight, add 100 parts of pure water and 0.5 part of gelatin into the pressure reactor, and stir evenly.

[0029] Step 2. Preparation of oil phase

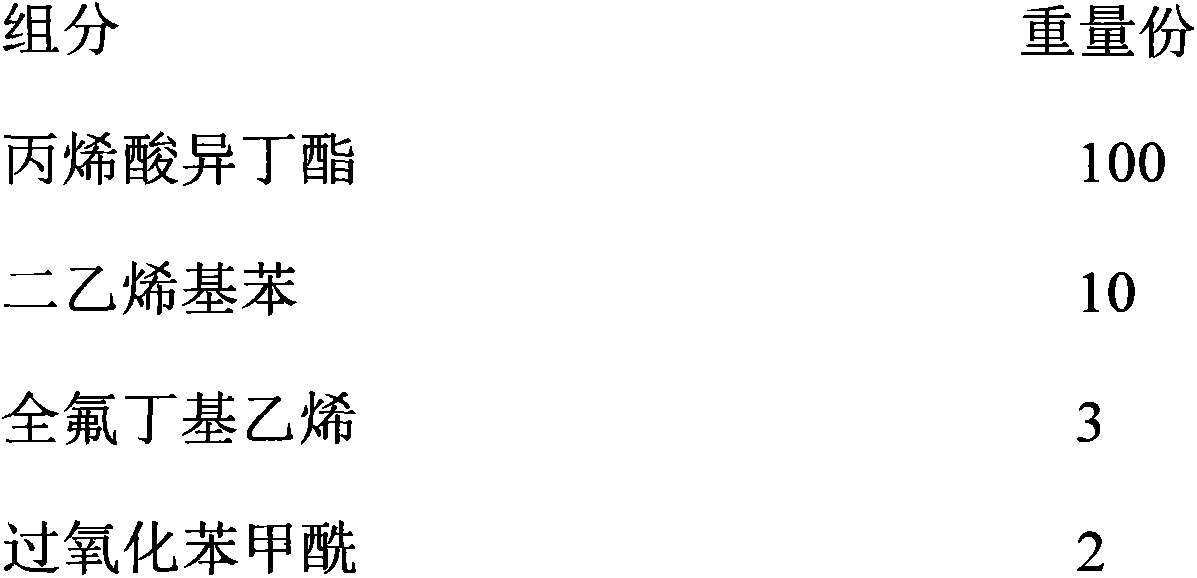

[0030] Mix the oil phase components in the following proportions in a beaker and stir evenly;

[0031]

[0032] Step 3. Suspension Polymerization

[0033] Add the oil phase solution prepared in the beaker in step 1.2 to the pressure reactor equipped with the prepared water phase in step 1.1, react at 80°C for 16 hours, discharge the material after the reaction, and wash the microspheres until The water is clear, and the product is obtained. The number is SX-1

Embodiment 2

[0035] Step 1. Preparation of water phase

[0036] In parts by weight, add 100 parts of pure water and 2 parts of gelatin into the pressure reactor, and stir evenly.

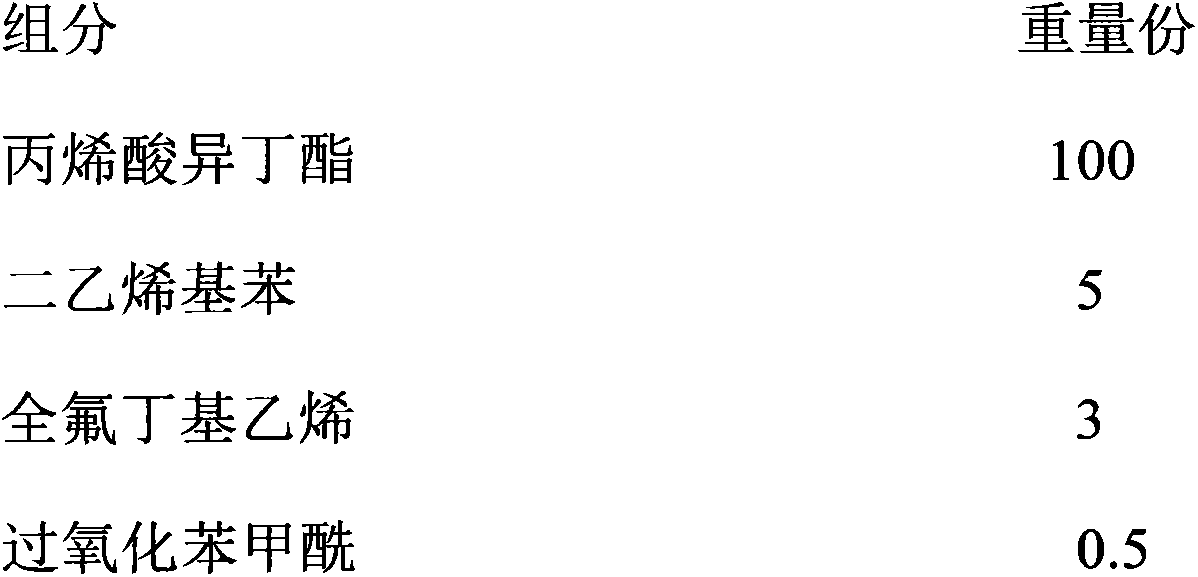

[0037] Step 2. Preparation of oil phase

[0038] Mix the oil phase components in the following proportions in a beaker and stir evenly;

[0039]

[0040] Step 3. Suspension Polymerization

[0041] Add the oil phase solution prepared in the beaker in step 1.2 to the pressure reactor equipped with the prepared water phase in step 1.1, react at 60°C for 20h, discharge the material after the reaction, and wash the microspheres until The water is clear, and the product is obtained. The number is SX-2

Embodiment 3

[0043] Step 1. Preparation of water phase

[0044] In parts by weight, add 100 parts of pure water and 1 part of gelatin into the pressure reactor, and stir evenly.

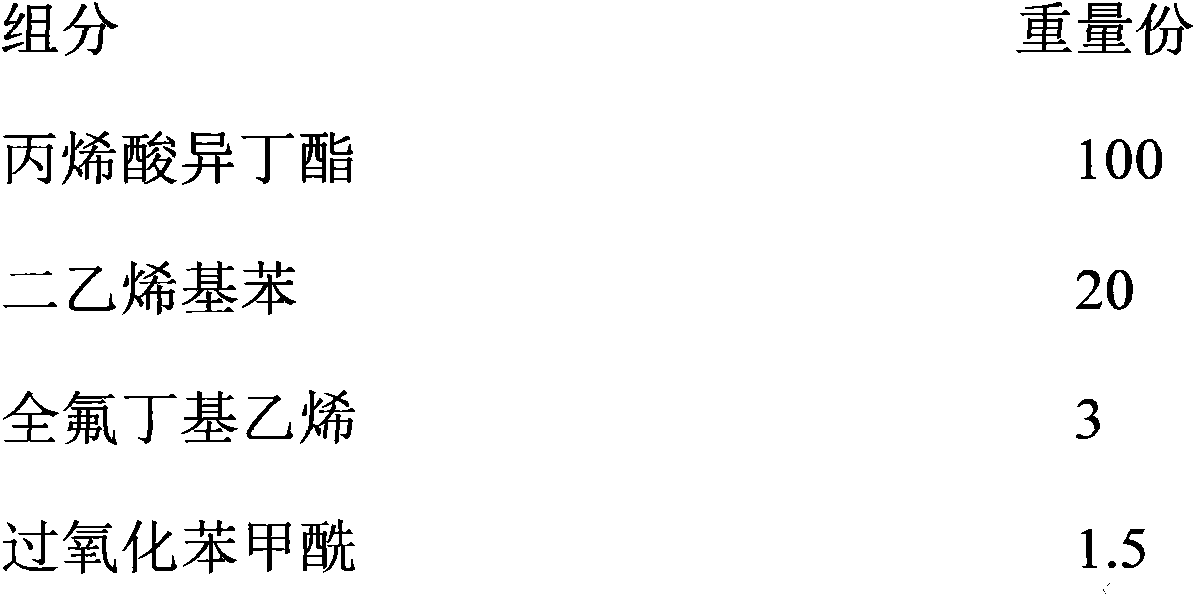

[0045] Step 2. Preparation of oil phase

[0046] Mix the oil phase components in the following proportions in a beaker and stir evenly;

[0047]

[0048] Step 3. Suspension Polymerization

[0049] Add the oil phase solution prepared in the beaker in step 1.2 to the pressure reactor equipped with the prepared water phase in step 1.1, react at 90°C for 8 hours, discharge the material after the reaction, and wash the microspheres until The water is clear, and the product is obtained. The number is SX-3

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com