Starlike isoprene-styrene block copolymer and preparation method thereof

A styrene block and polystyrene block technology, which is applied in the field of polymer material synthesis and preparation, can solve the problems of wide and complex polymer molecular weight, and achieve the effects of strong thickening ability, convenient operation and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

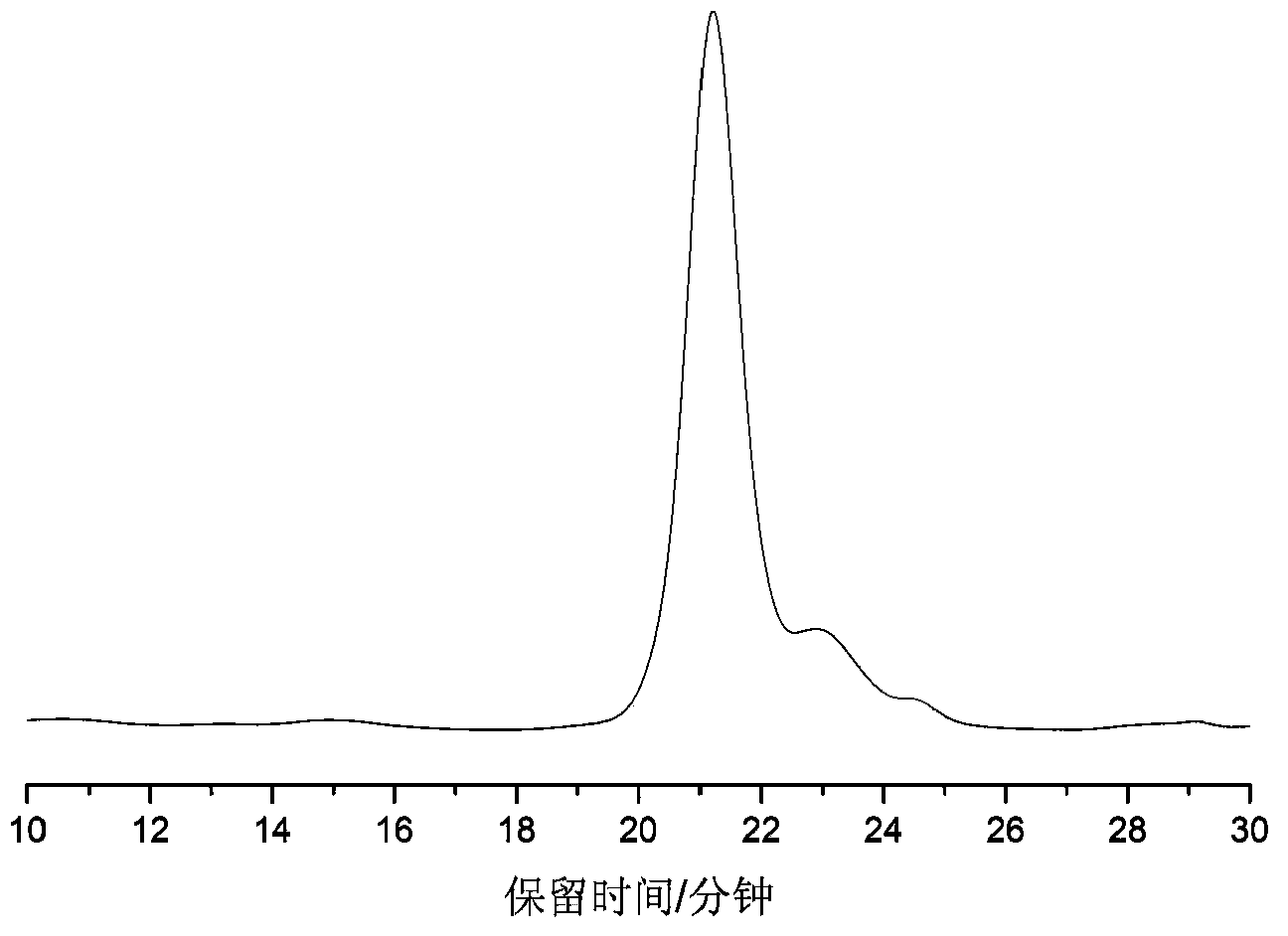

[0021] In a 500mL glass reaction bottle with magnetic stirring, add 90g cyclohexane and 7.5g isoprene, raise the temperature to 50°C, add 1.0mmol n-butyllithium initiator, when the polymerization reaction reaches 60 minutes, the isoprene The pentadiene polymerization reaction is completely completed, that is, the isoprene is completely consumed, and the polyisoprene block PI is obtained. Add 2.5 g of styrene and continue the reaction for 90 minutes until all styrene monomers are consumed to obtain polystyrene block S. The reaction temperature is lowered from 50°C to 20°C, adding tetrahydrofuran polar additives and divinylbenzene coupling agent for coupling reaction, wherein the molar ratio of tetrahydrofuran to n-butyllithium is 3:1, divinylbenzene to n-butyl The molar ratio of the base lithium is 3:1, and the divinylbenzene coupling agent is added dropwise, with an interval of 20 minutes each time. After all the divinylbenzene coupling agents are added, the reaction is contin...

Embodiment 2

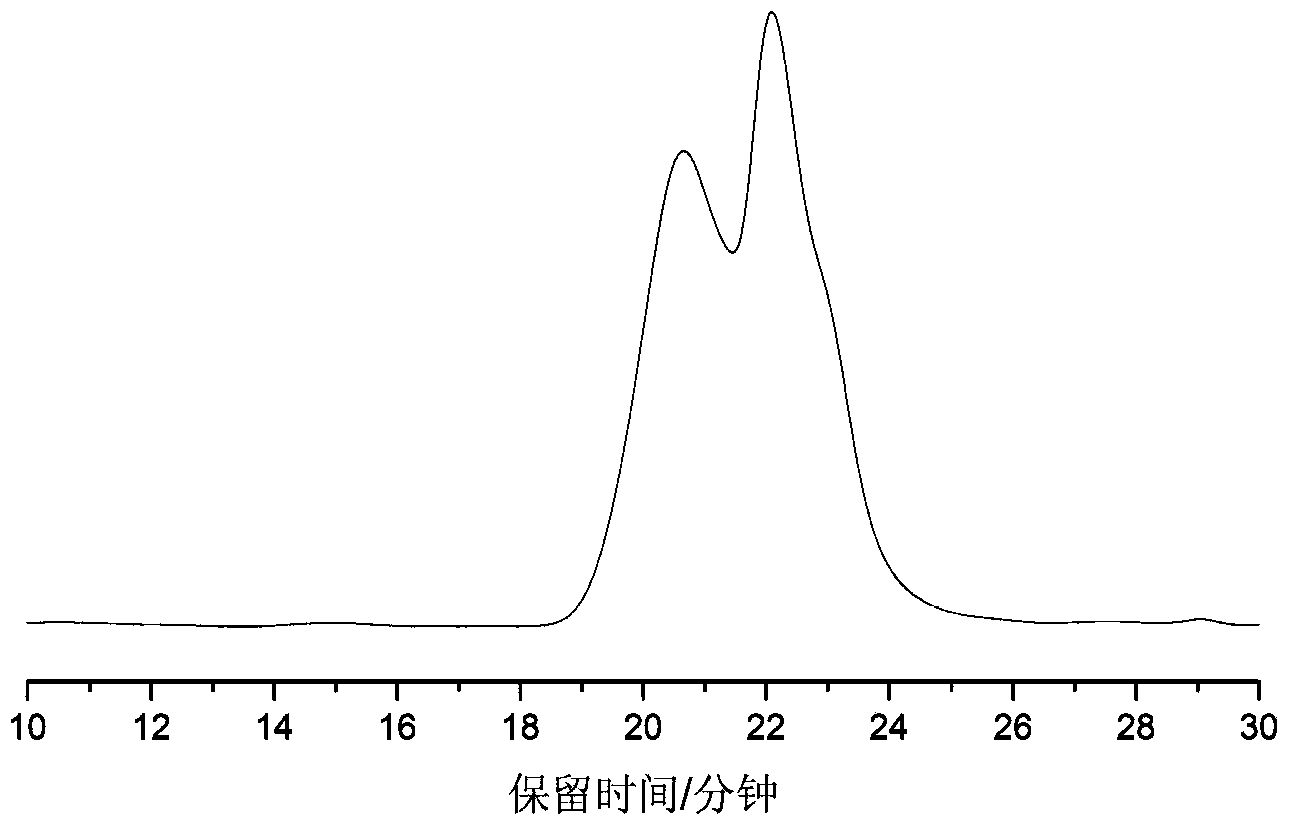

[0025]In a 500mL glass reaction bottle with magnetic stirring, add 90g cyclohexane and 9.5g isoprene, heat up to 90°C, add 0.1mmol n-butyllithium Li initiator, when the polymerization reaction reaches 30 minutes The pentadiene polymerization reaction is completely completed, that is, the isoprene is completely consumed, and the polyisoprene block PI is obtained. Then add 0.5 g of styrene and continue the reaction for 60 minutes until all the styrene monomers are consumed to obtain polystyrene blocks. Cool down to 50°C, add tetrahydrofuran (THF) and divinylbenzene (DVB) for coupling reaction, where THF: Li (molar ratio) = 1:1, DVB: Li (molar ratio) = 3:1, DVB is added The method is to add dropwise, with an interval of 15 minutes each time. After all the DVB is added, the reaction is continued for 120 minutes, and a terminator containing 2,6,4-anti-aging agent is added to terminate the reaction; then the glue is settled by the traditional method, Drying in a vacuum oven at 50°C...

Embodiment 3

[0027] In a 500mL glass reaction bottle with magnetic stirring, add 90g cyclohexane and 5g isoprene, the temperature of the water bath is 20°C, add n-butyllithium Li initiator, when the polymerization reaction reaches 120 minutes, the isoprene The olefin polymerization reaction is all completed, that is, the isoprene is completely consumed, and the polyisoprene block PI is obtained; 5 g of styrene is added, and the reaction is continued for 150 minutes until the styrene monomer is completely consumed, and the polystyrene block PI is obtained. Section; add tetrahydrofuran (THF) and divinylbenzene (DVB) for coupling reaction, where THF: Li (molar ratio) = 5: 1, DVB: Li (molar ratio) = 1: 1, DVB is added in a split Dropping each time with an interval of 15 minutes. After all the DVB is added, continue the reaction for 180 minutes, and add a terminator containing 2,6,4-anti-aging agent to terminate the reaction. Subsequently, the glue solution was settled by traditional methods, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com