Method for preparing carbon black through wet granulation

A technology of wet granulation and granular carbon black, which is applied in the chemical industry, can solve problems such as temperature fluctuations of carbon black at the outlet of the dryer, achieve stable quality, prevent the temperature from being too low, and avoid the effects of product combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

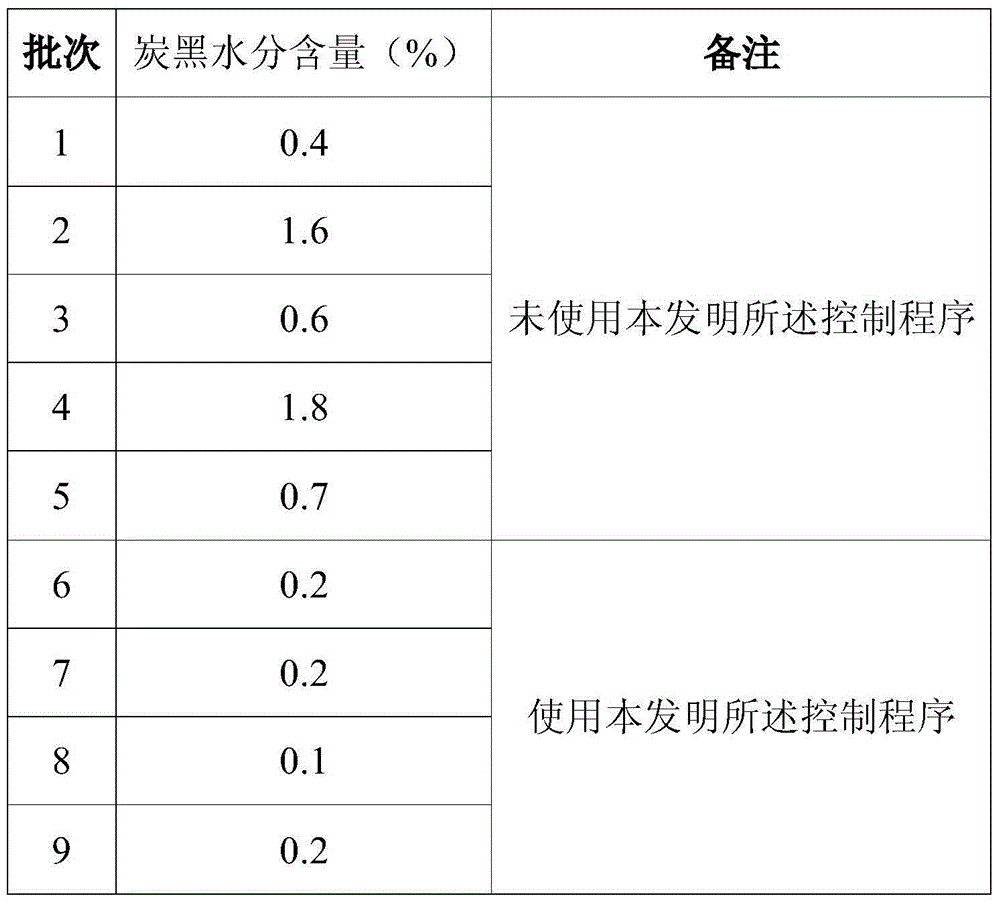

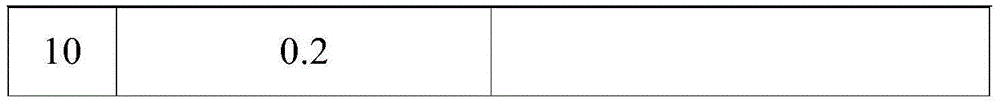

Examples

Embodiment 1

[0040]The hot air preheated by the air preheater to 550-650°C is provided by the main supply fan, sent to the combustion chamber of the reaction furnace through the hot air pipeline, mixed with the preheated and fully atomized fuel, and burned. The temperature range is 1500~1800℃. After the raw oil is preheated to 130-170°C by the raw oil preheater, it is sprayed from the rear of the combustion chamber of the reaction furnace, atomized and sheared (the force of the high-temperature air flow on the oil droplets breaks the oil droplets, thereby further Atomization), the cracking reaction is carried out in the reaction section of the reaction furnace, and the carbon black flue gas including powdered carbon black and tail gas is produced.

[0041] The carbon black flue gas is quenched once in the quenching section of the reaction furnace, then passes through the air preheater and the raw material oil preheater in turn, and finally undergoes secondary quenching to reduce the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com