Karst area drilling cast-in-place pile structure and construction method

A bored-in-place pile and regional technology, which is applied in the field of foundation engineering, can solve the problems of large foundation vibration, affecting the bearing capacity of the pile, and high requirements for the compactness of the backfill, and achieves the effect of strengthening the bond strength and increasing the strength of the soil body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In this embodiment, the binding and welding construction requirements for the main reinforcement of bored cast-in-situ piles, the construction requirements for backfilling the clay flake mixture at the karst cave, the drilling and installation construction requirements for prestressed anchor cables, and the tension construction requirements will not be repeated in this embodiment. The key points Embodiments of the invention are set forth concerning structures.

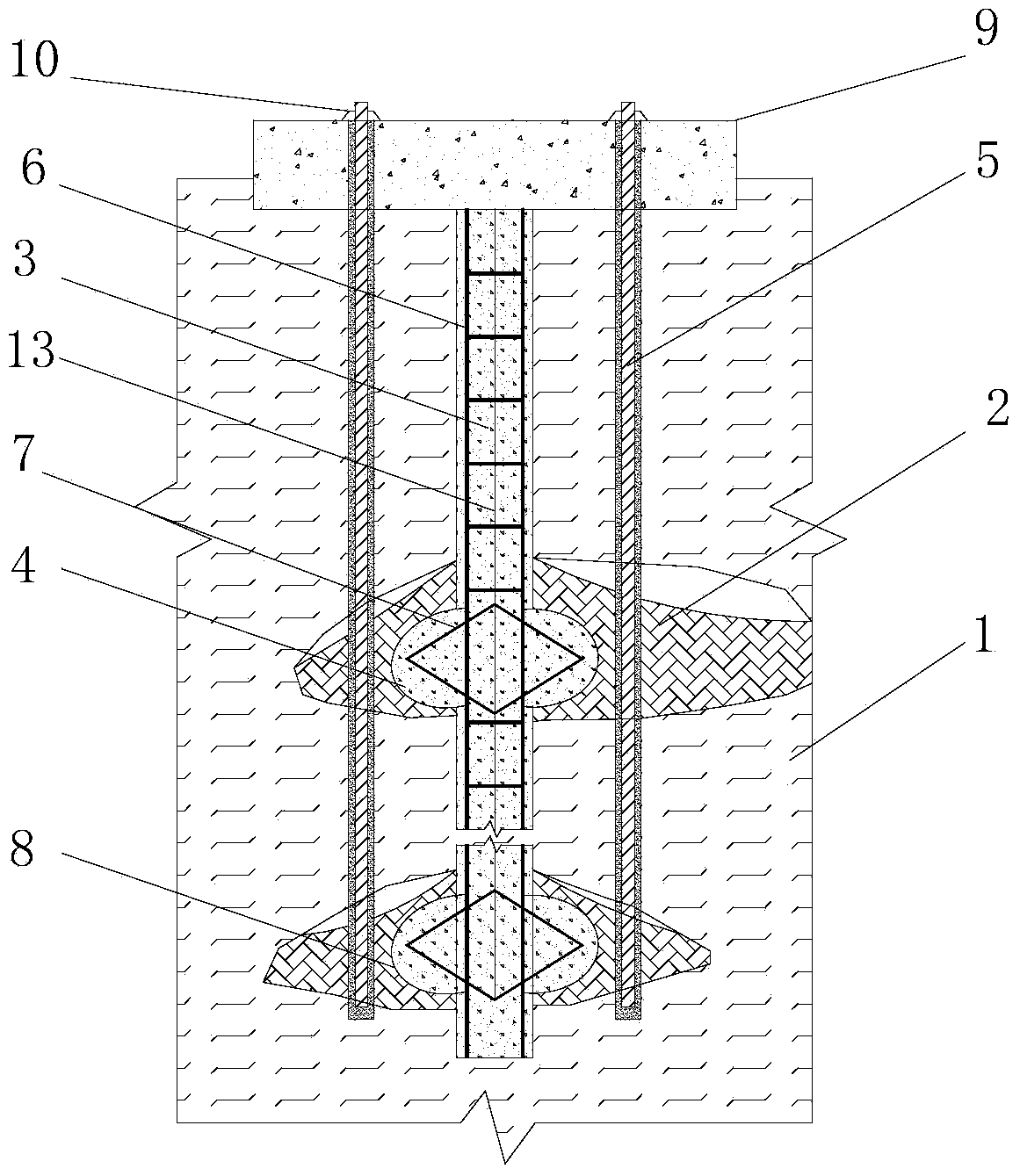

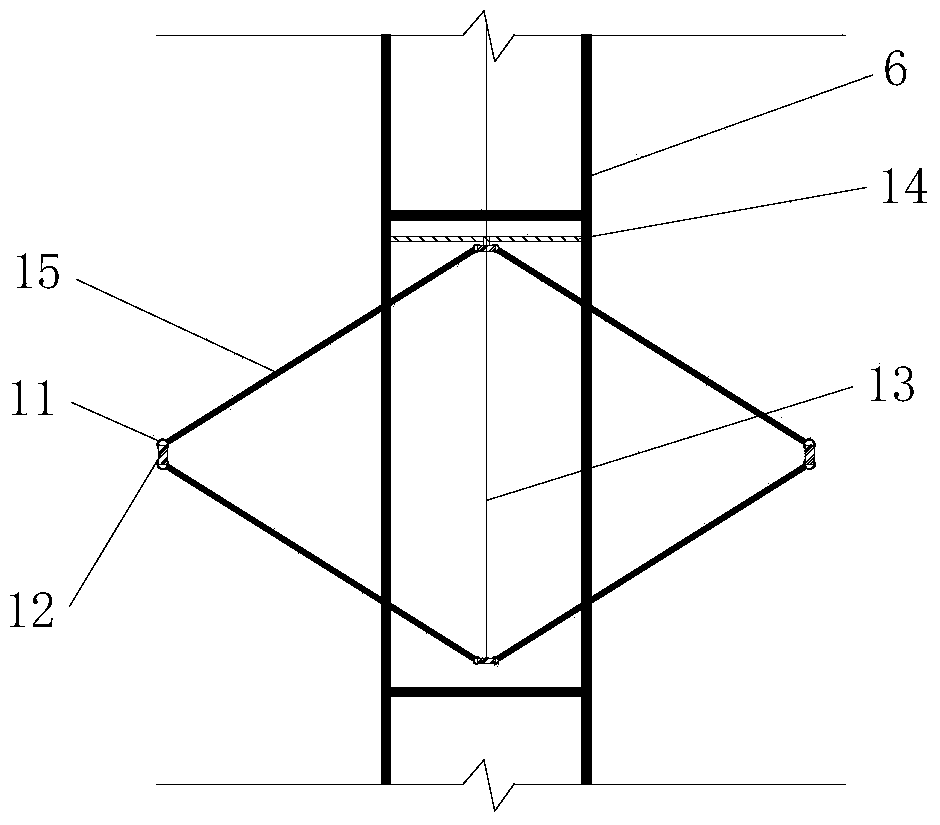

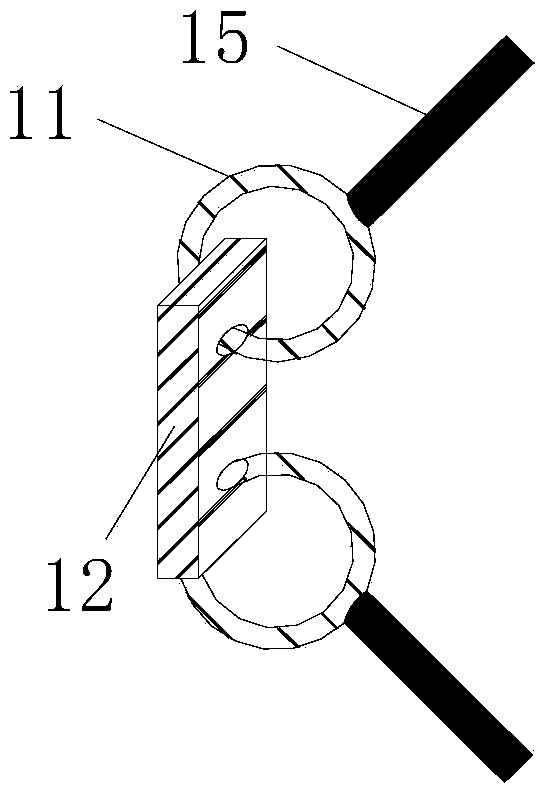

[0037] figure 1 It is a structural schematic diagram of the bored pile structure in the karst area of the present invention, figure 2 It is a schematic diagram of the structure of the extruded and expanded steel cage inside the expanded pile body at the karst cave, refer to figure 1 , figure 2 As shown, the structure of the bored pile in the karst area of the present invention is mainly composed of the bored pile 3, the bag grouting body 4, and the prestressed anchor cable 5.

[0038] One or more kars...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com