Heat supply unit combining compression heat pump with water heating device and heat supply method of heat supply unit

A compression heat pump and water heating device technology, applied in the energy field, can solve the problems of limited heat recovery capacity, no consideration of wind power abandonment of wind power to save energy, complex structure, etc., to ensure peak heating load and reduce heating Cost, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

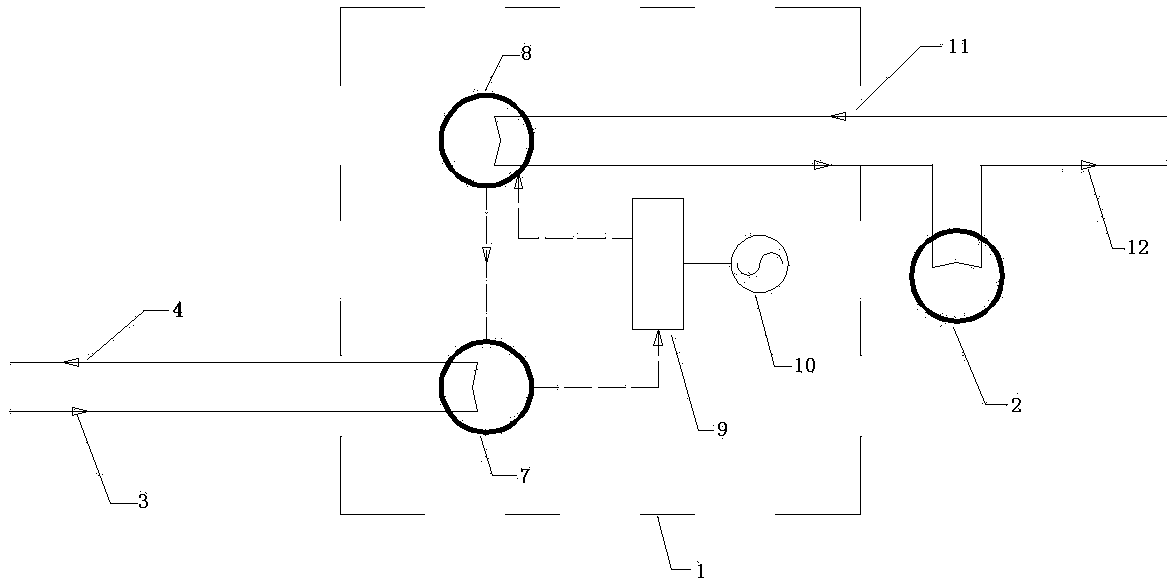

[0048] Such as figure 1 As shown, the circulating water used to cool the exhaust steam of the steam turbine in the power plant absorbs heat in the steam turbine condenser 5, and then enters the electric energy-driven compression heat pump evaporator 7 through the circulating water inlet pipe, and is absorbed by the low-temperature working medium in the evaporator 7 After cooling, the water is transported back to the steam turbine condenser 5 through the circulating water outlet pipe 4, and a new round of heat-absorbing and cooling process for the exhaust steam of the steam turbine is started, and so forth. The compression heat pump system 1 connects the evaporator 7 , the condenser 8 , and the compressor 9 sequentially through internal connecting pipelines to form a loop for the circulating use of working fluid in the compression heat pump system 1 . The working fluid in the evaporator 7 of the compression heat pump system absorbs the heat of low-grade circulating water, and t...

Embodiment 2

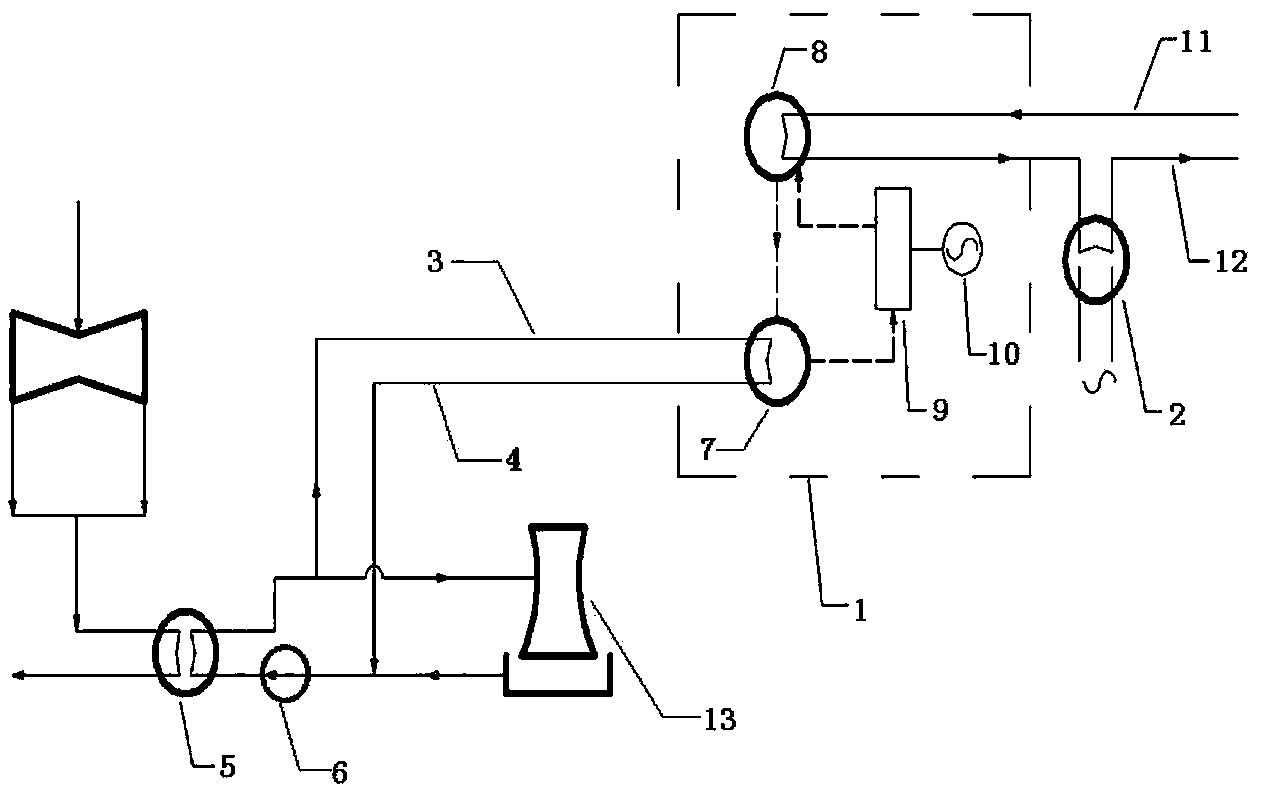

[0050] Such as figure 2 As shown, the circulating water used to cool the exhaust steam of the steam turbine in the power plant absorbs heat in the steam turbine condenser 5 and enters the electric energy-driven compression heat pump evaporator 7 through the circulating water inlet pipe 3, and is absorbed by the low-temperature working medium in the evaporator 7. After the heat is cooled, it is sent back to the condenser of the steam turbine through the circulating water outlet pipe 4, and a new round of heat absorption and cooling process for the exhaust steam of the steam turbine is started, and so forth. In this embodiment, in addition to being connected to the evaporator 7 of the compression heat pump system, the steam turbine condenser 5 is also connected in parallel with a circuit entering the cooling tower 13 to provide an additional cooling device for circulating water that is surplus or does not reach the temperature required for cooling the steam turbine. , the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com