Multilayer high-power nearly-spherical nano friction generator and application thereof

A nano-friction and generator technology, applied in the direction of friction generators, can solve the problems of poor contact area effect, etc., and achieve the effects of stable output performance, improved output characteristics, and high output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Such as Figure 5 As shown, the nano friction generator of this embodiment is an opaque hollow ball, and the ball radius of the power generating ball is 2 cm. The triboelectric generator includes three layers, a first electrode layer 51, a high molecular polymer layer 52 disposed on the first electrode, and a second electrode layer 53 disposed on the high polymer layer. The preparation method is as follows:

[0083] (1) Preparation of the hollow sphere core: The hollow sphere core is prepared by the conventional template method. Specifically, the sacrificial silicon sphere is used as the template to copolymerize styrene and KH570 monomer through the dispersion polymerization method. The SiOH group is introduced into the surface of the PSt latex particles through chemical bonds, and then an ethanol solution of butyl silicate (TEOS) is added dropwise to cause the TEOS to undergo polycondensation reaction with the copolymer obtained in the previous step, thereby obtaining a S...

Embodiment 2

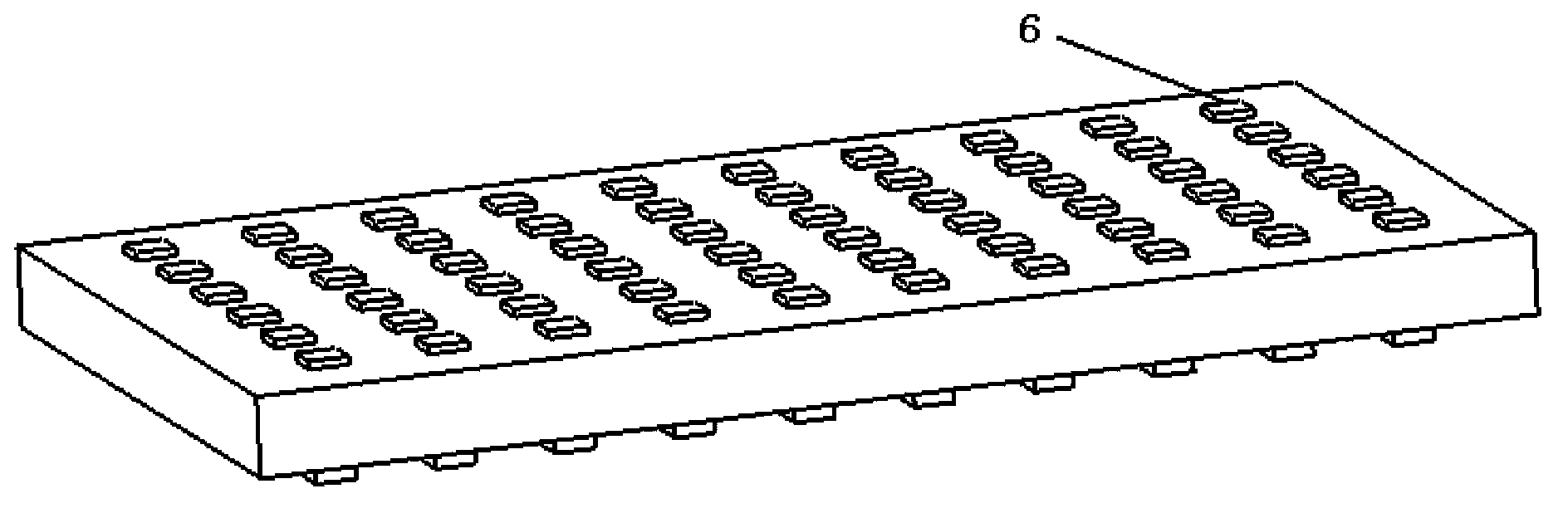

[0088] Such as Image 6 As shown, the nano friction generator of this embodiment is an opaque solid ball, and the ball radius of the power generating ball is 2 cm. The triboelectric generator includes three layers, a first electrode layer 61, a high molecular polymer layer 62 disposed on the first electrode, and a second electrode layer 63 disposed on the high molecular polymer layer. The inner core material is rubber. The preparation method is as follows:

[0089] (1) A solid rubber ball with a radius of 2 cm is obtained by conventional injection molding.

[0090] (2) Gold is plated on the surface of the rubber solid ball by magnetron sputtering to form the first electrode layer 61, and the solid ball is put into the polyimide solution to coat the polymer evenly on the surface of the ball. After the ball is lifted out of the liquid surface, it is dried. After drying, sandpaper is used to polish the surface of the polyimide layer to form a Wiener concave-convex structure to form ...

Embodiment 3

[0094] Such as Figure 7 As shown, the nano friction generator of this embodiment is a transparent hollow ball, and the ball radius of the power generating ball is 5 cm. The triboelectric generator includes four layers, a first electrode layer 71, a first high polymer layer 72 disposed on the first electrode, a second high polymer layer 74, and a second high polymer layer 74 The second electrode layer 73. The preparation method is as follows:

[0095] (1) Preparation of the hollow sphere core: The hollow sphere core is prepared by the conventional template method. Specifically, the sacrificial silicon sphere is used as the template to copolymerize styrene and KH570 monomer through the dispersion polymerization method. The SiOH group is introduced into the surface of the PSt latex particles through chemical bonds, and then an ethanol solution of butyl silicate (TEOS) is added dropwise to cause the TEOS to undergo polycondensation reaction with the copolymer obtained in the previo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com