Hydraulic control system

A technology of hydraulic control system and controller, applied in the direction of fluid pressure actuation system components, presses, manufacturing tools, etc., can solve problems such as workpiece cannot be formed, product damage, insufficient pressure, etc., to improve the qualification rate and strong practicability , Reduce the effect of stretching scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

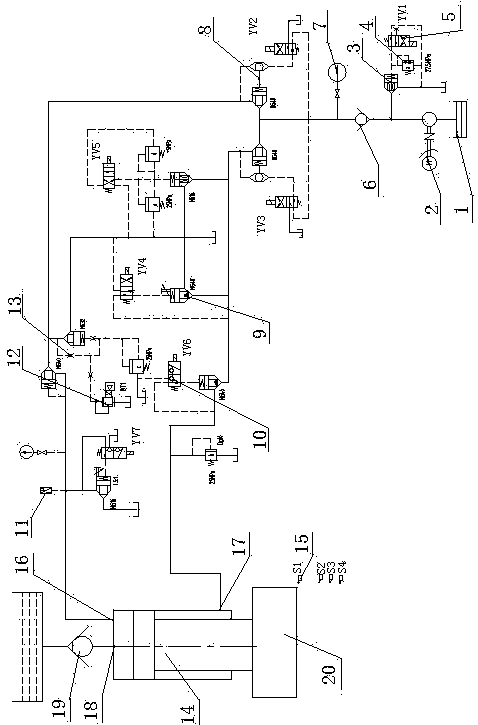

[0012] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, this embodiment provides a hydraulic control system, including a master cylinder 14 and an oil tank 1, the piston cylinder of the master cylinder 14 is connected with a slider 20, and also includes a slider 20 connected to the piston cylinder for controlling the master cylinder 14 The PLC controller of down, return, down speed and pressure is provided with a proximity switch 15 in the extending direction of the piston cylinder of the master cylinder 14, and the fuel tank 1 passes through the constant power variable pump 2, the cartridge valve 3, Relief valve 4, two-position four-way solenoid valve 5, one-way valve 6, cartridge valve with shuttle valve 8, throttle valve 13, proportional valve 12 are connected to oil port one 16 of the master cylinder 14, and the shuttle valve The valve cartridge valve 8 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com