The synthetic method of substituted nitroaniline

A technology of nitroaniline and synthesis method, applied in the formation/introduction of nitro/nitroso group, preparation of amino compounds, chemical instruments and methods, etc., can solve problems such as environmental pollution, unsafe production process, cumbersome and complicated, and achieve The effect of simple post-processing, less environmental pollution and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

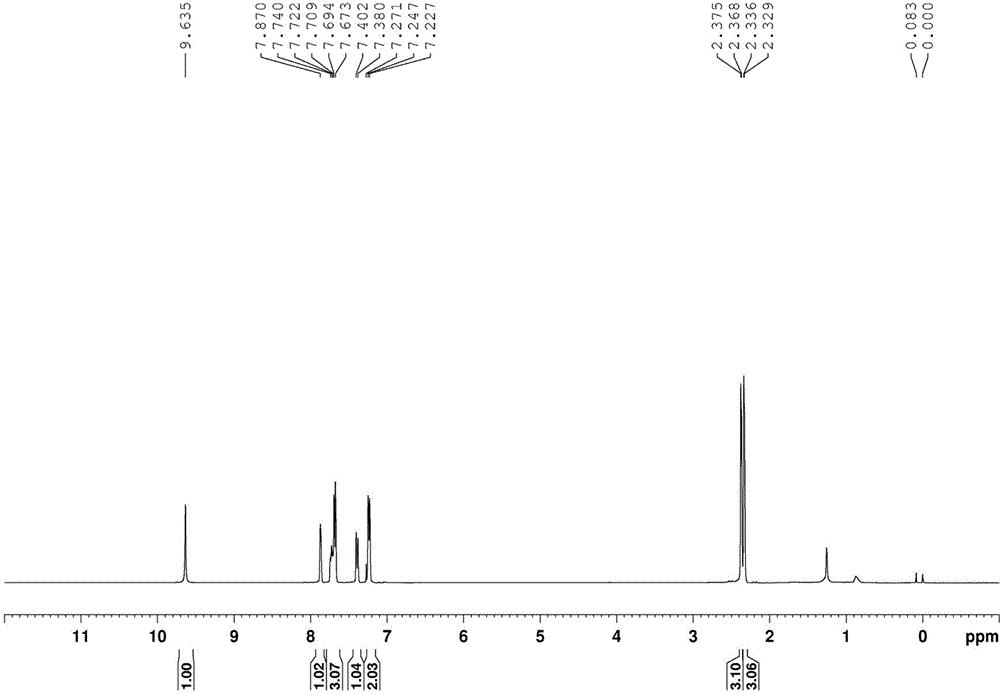

Embodiment 1

[0031] , Ts is p-toluenesulfonyl.

[0032] compound a (0.3mmol), 0.6mmol NaNO 2 and 0.2mmol potassium persulfate into the reaction vessel, add 3ml of nitromethane, and stir for 2 hours at 50°C; Volume ratio 1:10) was used as the eluent to pass through a silica gel column to obtain the product a' with a yield (98%).

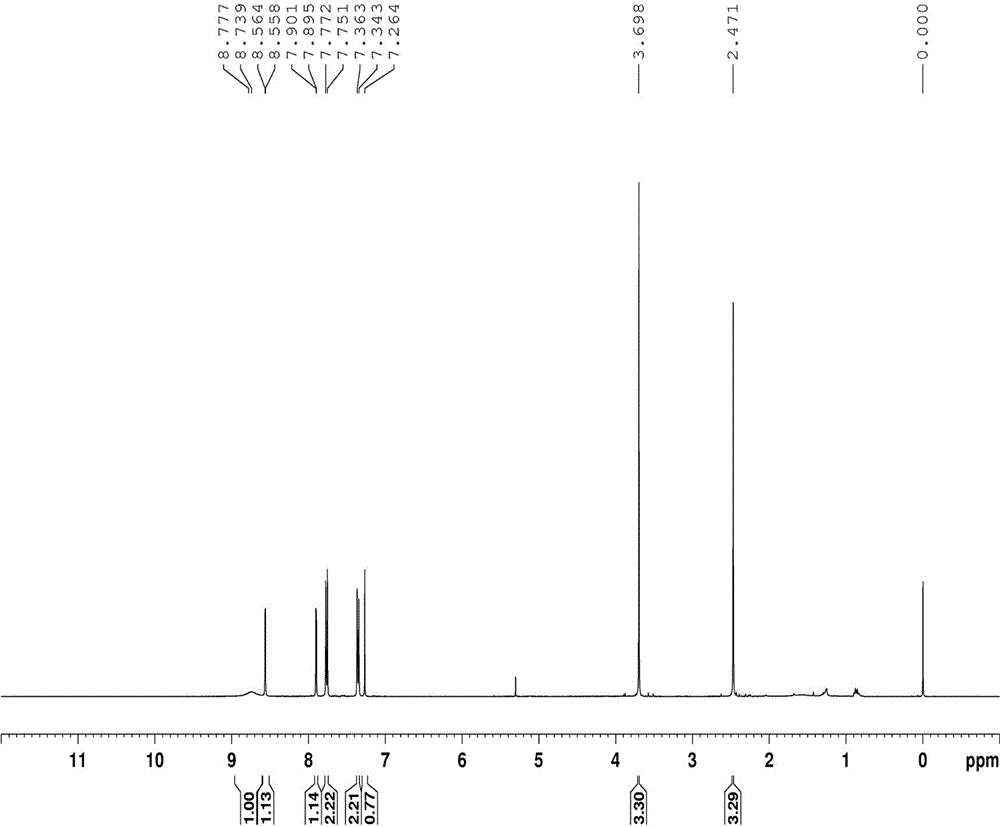

Embodiment 2

[0034]

[0035] compound b (0.3mmol), 0.6mmol NaNO 2 and 0.2 mmol of potassium hydrogen persulfate were added to the reaction vessel, 3ml of nitromethane was added, and stirred at 50°C for 3 hours; (volume ratio 1:8) was used as the eluent to pass through a silica gel column to obtain products b' (50% yield) and b'' (32% yield).

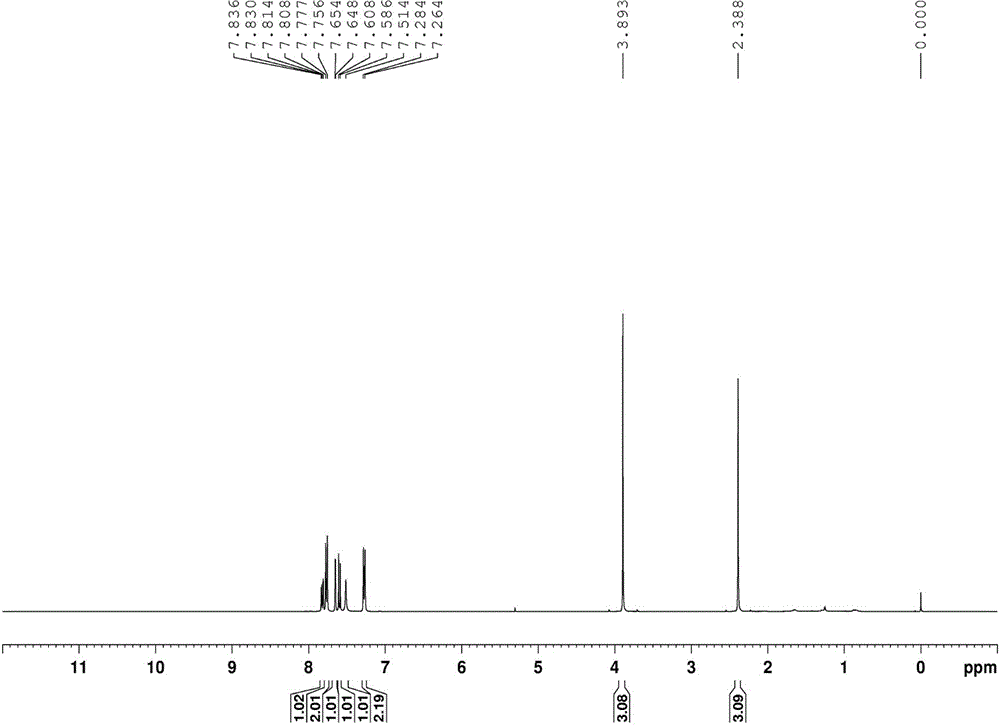

Embodiment 3

[0037]

[0038] compound c (0.3mmol), 0.6mmol NaNO 2 and 0.2mmol of potassium hydrogen persulfate were added to the reaction vessel, 3ml of nitromethane was added as solvent, and stirred at 50°C for 3 hours; after the detection reaction was completed, the nitromethane was removed by rotary evaporation, and the The mixed solution (volume ratio 1:8) was used as the eluent to pass through the silica gel column to obtain the product c' with a yield of 62%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com