Manufacturing method of heat insulating oil casing

A manufacturing method and oil casing technology, which is applied in the fields of oil production tools and its manufacture, the manufacture of heat-insulated oil casing, and steam injection, and can solve the problems of heat loss at coupling joints, cementing casing damage, and waste of economic benefits and other problems, to achieve the effect of improving heat insulation performance, prolonging heat insulation life, and solving the problem of sleeve damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

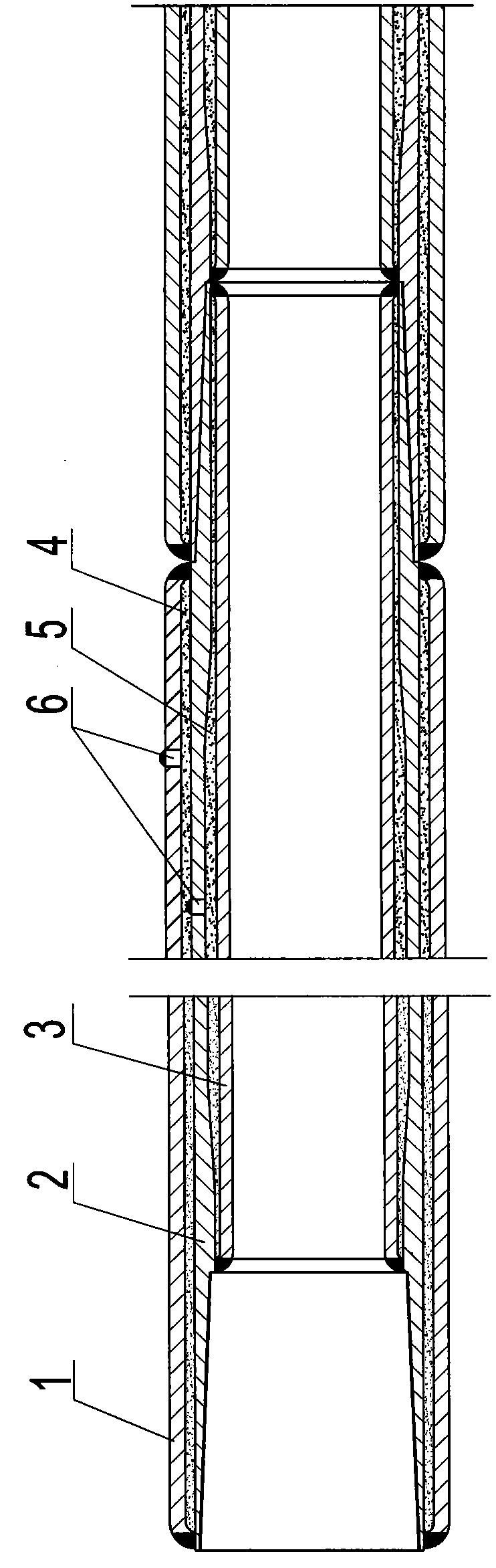

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] exist figure 1 In the shown embodiment: an outer pipe 1, an intermediate pipe 2 and an inner pipe 3 comprising a steel clearance suit, wherein one end of the intermediate pipe 2 is processed with an internal thread, and the other end is processed with an external thread, and one end of the intermediate pipe 2 is processed with an internal thread and an external thread. Pipe 1 is welded at the pipe end, and welded with inner pipe 3 at the reserved internal thread length, the end of the intermediate pipe 2 with external thread is welded with outer pipe 1 at the reserved external thread length, and with inner pipe 3 at the pipe end Welding; the annulus formed by the outer pipe 1 and the middle pipe 2 is filled with heat insulating material and evacuated to form the first heat insulation layer 4, and the annulus of the middle pipe 2 and the inner pipe 3 is evacuated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com