Long-service-life and high-specific-capacity poly-dopamine-coated hollow sulfur microsphere composite positive electrode material and preparation method thereof

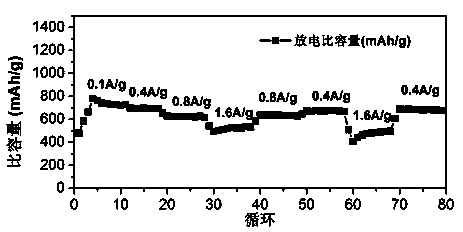

A composite positive electrode material, polydopamine technology, applied in battery electrodes, electrical components, non-aqueous electrolyte storage batteries, etc., can solve the problems that restrict the marketization of lithium-sulfur batteries, poor cycle performance and poor rate performance of lithium-sulfur batteries, and achieve high The effects of rate performance, high specific capacity, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

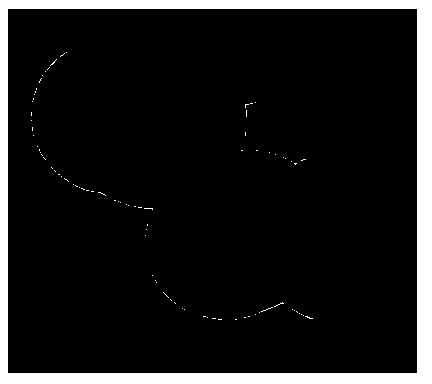

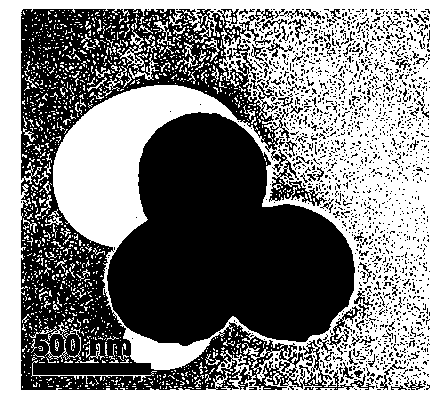

[0027] first step: Slowly add 50 milliliters of 4% sodium thiosulfate aqueous solution into 100 milliliters of 3% polyvinylpyrrolidone (PVP, molecular weight 40,000) aqueous solution, and stir at a rate of 300 rpm for 60 minutes; then Slowly add 50 ml of hydrochloric acid aqueous solution with a mass concentration of 2%, and stir for 120 minutes at a rate of 300 rpm. After the reaction is completed, the product is filtered and cleaned to obtain hollow sulfur microspheres with a particle diameter of about 460 nanometers. (See figure 1 ).

[0028] Step two: Disperse the hollow sulfur microspheres into 100 ml of dopamine aqueous solution with a mass concentration of 1% and a pH value of 8.5, and stir at a rate of 200 rpm for 16 hours. After the reaction is completed, the product is filtered, washed and vacuum-dried ( The absolute vacuum degree is 1000 Pa, the drying temperature is 60 ° C, and the drying time is 10 hours), and the polydopamine-coated hollow sulfur microspher...

Embodiment 2

[0032] first step: Except that polyvinylpyrrolidone with a molecular weight of 50,000 was used as the surfactant, other operating steps were the same as in Example 1.

[0033] Step two:Disperse the hollow sulfur microspheres into 100 ml of dopamine aqueous solution with a mass concentration of 2% and a pH value of 8.5, and stir at a rate of 500 rpm for 10 hours. After the reaction is completed, the product is filtered, washed and vacuum-dried ( The absolute vacuum degree is 5000 Pa, the drying temperature is 200°C, and the drying time is 10 hours), and finally polydopamine-coated hollow sulfur microspheres with a particle diameter of 540 nm are obtained.

[0034] third step: Same as Embodiment 1.

[0035]

Embodiment 3

[0037] first step: Slowly pour 50 ml of the pre-configured ammonium thiosulfate aqueous solution with a mass concentration of 3% into 100 ml of a 4% polyethylene glycol (molecular weight 1000) aqueous solution, and stir at a speed of 400 rpm 60 minutes; then 50 milliliters of hydrochloric acid aqueous solution with a mass concentration of 1.8% was slowly added therein, and stirred at a speed of 500 rpm for 120 minutes. After the reaction was completed, the product was filtered and cleaned to obtain a particle diameter of about 500 nanometers. hollow sulfur microspheres.

[0038] Step two: Disperse the hollow sulfur microspheres into 100 ml of dopamine aqueous solution with a mass concentration of 1% and a pH value of 8.2, and stir at a rate of 200 rpm for 20 hours. After the reaction is completed, the product is filtered, washed and vacuum-dried (absolute The vacuum degree is 100 Pa, the drying temperature is 50°C, and the drying time is 15 hours), and finally polydopamine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com