System and method for deeply removing sulfur oxides in coal-fired flue gas

A flue gas purification system and a technology for burning coal flue gas, which are applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems of pollution, difficult to remove droplets, and high emission concentration, and improve the removal efficiency. , Solve the effect of acid corrosion and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

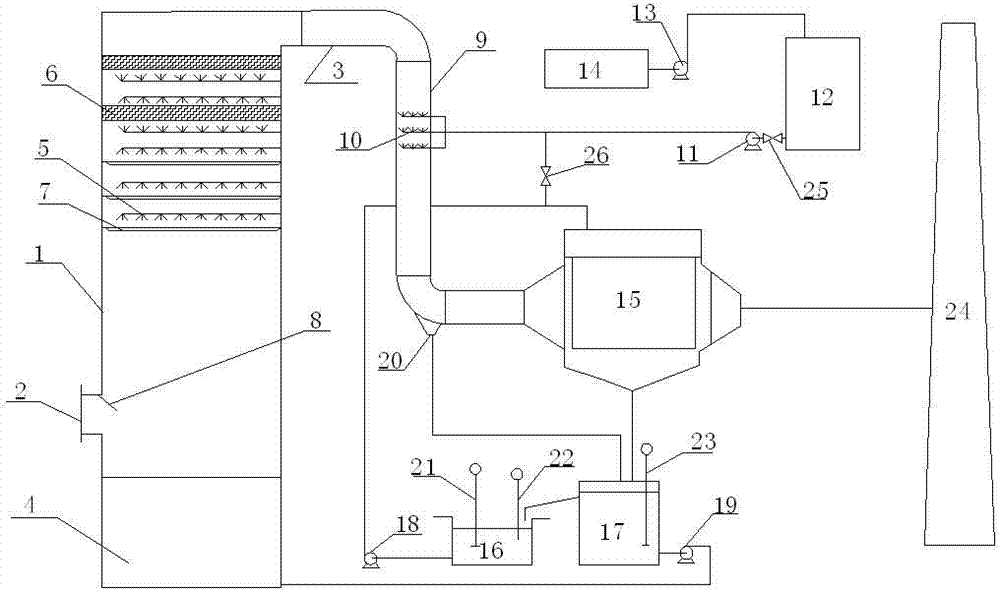

[0039] refer to figure 1 , a system for deep removal of sulfur oxides from coal-fired flue gas, the system includes a wet single-tower high-efficiency desulfurization system, an absorbent injection system and a wet-type electrostatic flue gas purification system, and the wet single-tower high-efficiency desulfurization system and The absorbent injection system is connected, the absorbent injection system is connected with the wet electrostatic flue gas purification system, and the wet electrostatic flue gas purification system is connected with the chimney 24 .

[0040] The wet single-tower high-efficiency desulfurization system includes a desulfurization tower 1, the lower part of the desulfurization tower 1 is provided with an air inlet 2, the upper part is provided with an air outlet 3, the lower part of the air inlet 2 is provided with a slurry pool 4, and the upper part of the slurry pool 4 is provided with There are 2 to 5 layers of spray layers 5 and 1 to 2 layers of de...

Embodiment 2

[0049] A method for deep removal of sulfur oxides from coal-fired flue gas, comprising the steps of:

[0050] (1) The coal-fired flue gas enters the desulfurization tower from the air inlet, and realizes SO 2 Concentration emission less than 50mg / Nm 3 , to achieve SO 3 The removal efficiency reaches 50%;

[0051] (2) After the coal-fired flue gas passes through the wet single-tower high-efficiency desulfurization system, it enters the absorbent injection system, and the lye sodium hydroxide or ammonia water is mixed with the coal-fired flue gas through the injection device to realize the removal of SO 2 further removal of SO 2 Concentration below 15mg / Nm 3 , part SO 3 formation of sulphate particles;

[0052] (3) After the coal-fired flue gas passes through the absorbent injection system, some excess lye entrained enters the wet electrostatic flue gas purification system, and the excess lye is efficiently removed by the wet electrostatic flue gas purification system; in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com