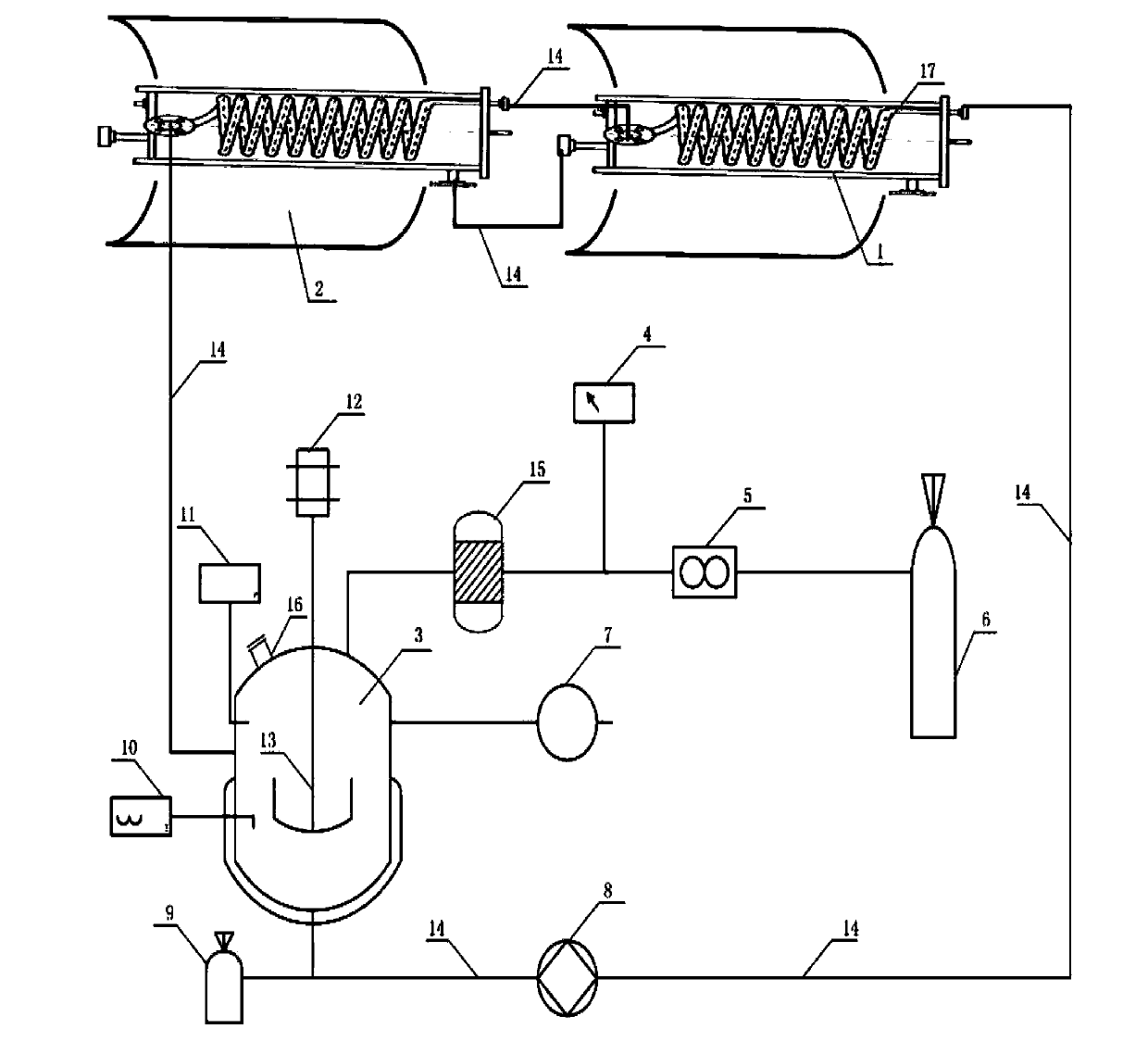

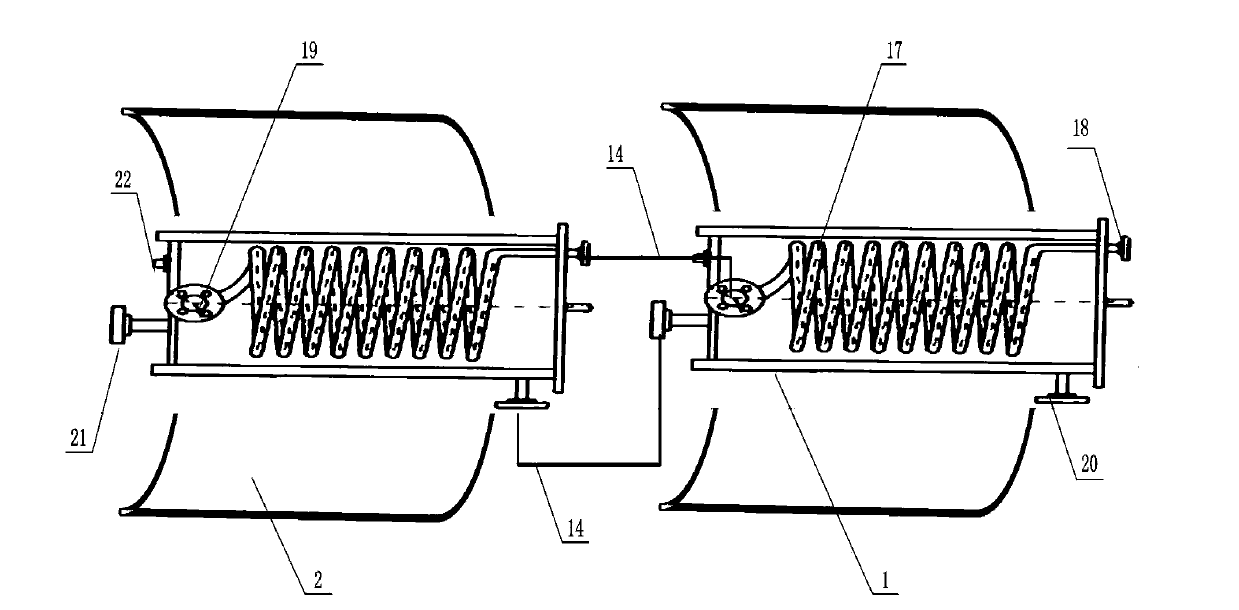

Reaction device for preparing hydrogen through solar photocatalysis

A photocatalytic reactor and reaction device technology, applied in separation and collection devices, new reaction devices, and hydrogen purification fields, can solve the problems of limited light-receiving area, sedimentation of photocatalysts, and limited sunlight utilization, etc., to improve stability, The effect of improving the efficiency of photocatalytic reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: set the parameters of the high-precision automatic solar tracking system on the axial solar concentrator so that it can track the sun in real time. The linear parabolic concentrator on the axial solar concentrator has a width of 0.5 meters and a length of 4 meters, the width of the focused spot produced by it is 0.10m. The serpentine coil reactor is made of thin glass tubes with an outer diameter of 0.008 meters and an inner diameter of 0.006 meters and a total length of 50 meters. The outer diameter of the serpentine coil reactor is 0.08 meters and the length is 4 meters. The catalyst CdS concentration added to the system was 1.0 g / L, the reaction solution was deionized water, and the total volume was 12 L. The circulation rate of the reaction liquid is 60.2mL / min, and the average direct solar radiation is 480W / m 2 Under certain conditions, the device can realize continuous and stable hydrogen production, with an average hydrogen production rate of 0.66L...

Embodiment 2

[0030] Embodiment 2: set the parameters of the high-precision automatic solar tracking system on the axial solar concentrator so that it can track the sun in real time. The linear parabolic concentrator on the axial solar concentrator has a width of 0.5 meters and a length of 4 meters, the width of the focused spot produced by it is 0.10m. The serpentine coil reactor is made of thin glass tubes with an outer diameter of 0.008 meters and an inner diameter of 0.006 meters and a total length of 50 meters. The outer diameter of the serpentine coil reactor is 0.08 meters and the length is 4 meters. The concentration of catalyst CdS added in the system is 1.0g / L, and the reaction solution is Na 2 S and Na 2 SO 3 The mixed solution, the concentration is 0.5mol / L, the total volume is 12L. The circulation rate of the reaction liquid is 60.2mL / min, and the average direct solar radiation is 480W / m 2 Under certain conditions, the device can realize continuous and stable hydrogen produ...

Embodiment 3

[0031] Embodiment 3: set the parameters of the high-precision automatic solar tracking system on the axial solar concentrator so that it can track the sun in real time. The linear parabolic concentrator on the axial solar concentrator has a width of 0.5 meters and a length of 4 meters, the width of the focused spot produced by it is 0.10m. The serpentine coil reactor is made of thin glass tubes with an outer diameter of 0.008 meters and an inner diameter of 0.006 meters and a total length of 50 meters. The outer diameter of the serpentine coil reactor is 0.08 meters and the length is 4 meters. The concentration of the catalyst P25 added in the system is 2.0g / L, the reaction solution is a methanol solution, the concentration is 5.0mol / L, and the total volume is 12L. The circulation rate of the reaction liquid is 60.2mL / min, and the average direct solar radiation is 480W / m 2 Under certain conditions, the device can realize continuous and stable hydrogen production, with an aver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com