Chromium-silver co-doped nano TiO2 photo-catalyst, and preparation method and use thereof

A photocatalyst, co-doping technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The invention provides a chromium-silver co-doped nano-TiO 2 The preparation method of the photocatalyst adopts the sol-gel method, and the specific operation steps are:

[0032] (1) Add 10mL of butyl titanate to 20mL of absolute ethanol, add dropwise 2mL of glacial acetic acid, and stir magnetically for 30 minutes until uniformly mixed to obtain solution A;

[0033] (2) Dissolve silver nitrate and ferric nitrate in 2mL of distilled water, pour into 20mL of absolute ethanol, add dropwise 2mL of glacial acetic acid, 2mL of dilute nitric acid (concentration 0.1mol / L), stir magnetically for 25 minutes until uniformly mixed, and obtain solution B The amount of silver nitrate added is 0.1% of the molar fraction of the corresponding titanium particles in the solution A obtained in step (1); the added amount of iron nitrate is 0.5% of the molar fraction of the corresponding titanium particles in the solution A obtained in step (1);

[0034] (3) Under the condition of vigorous...

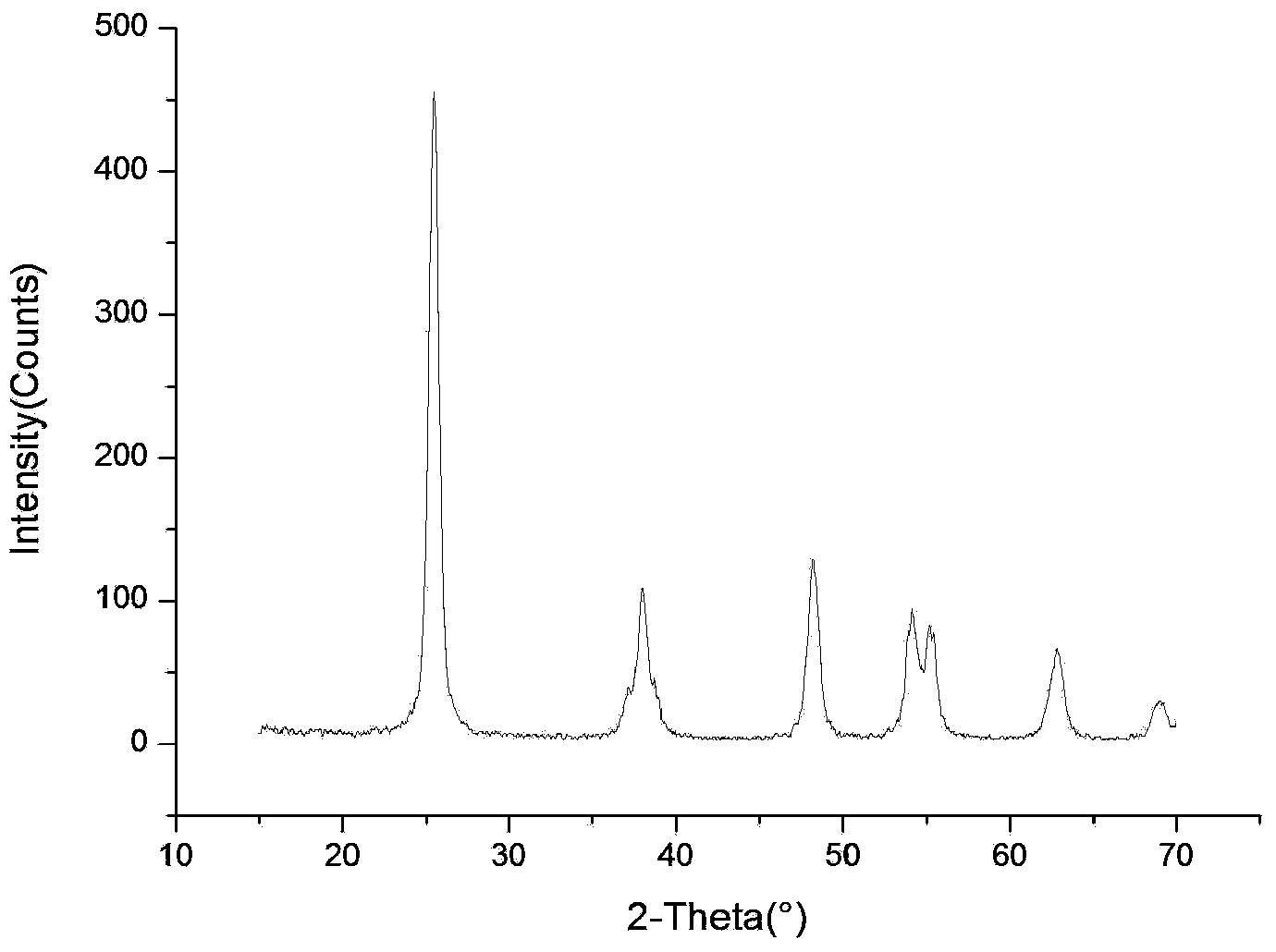

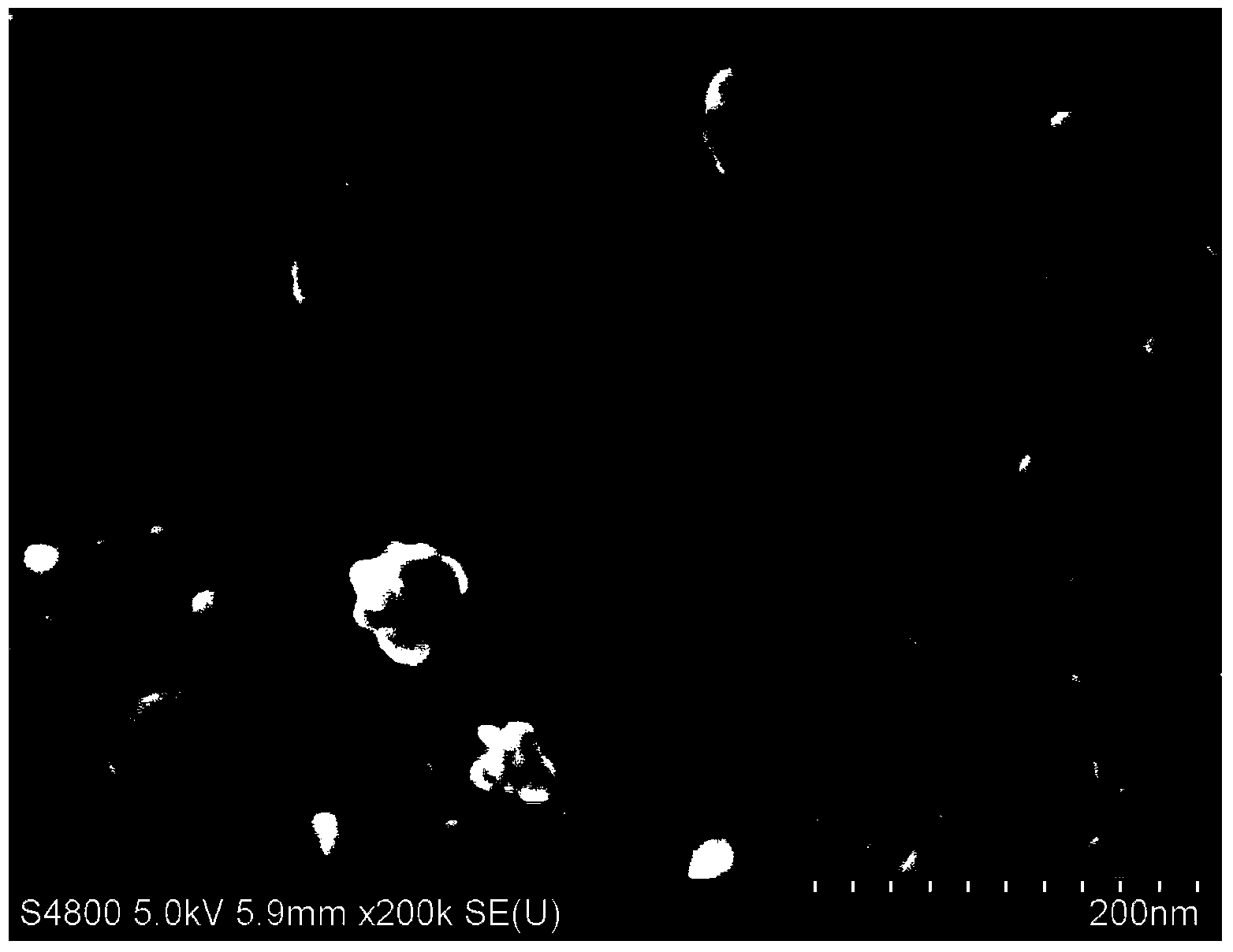

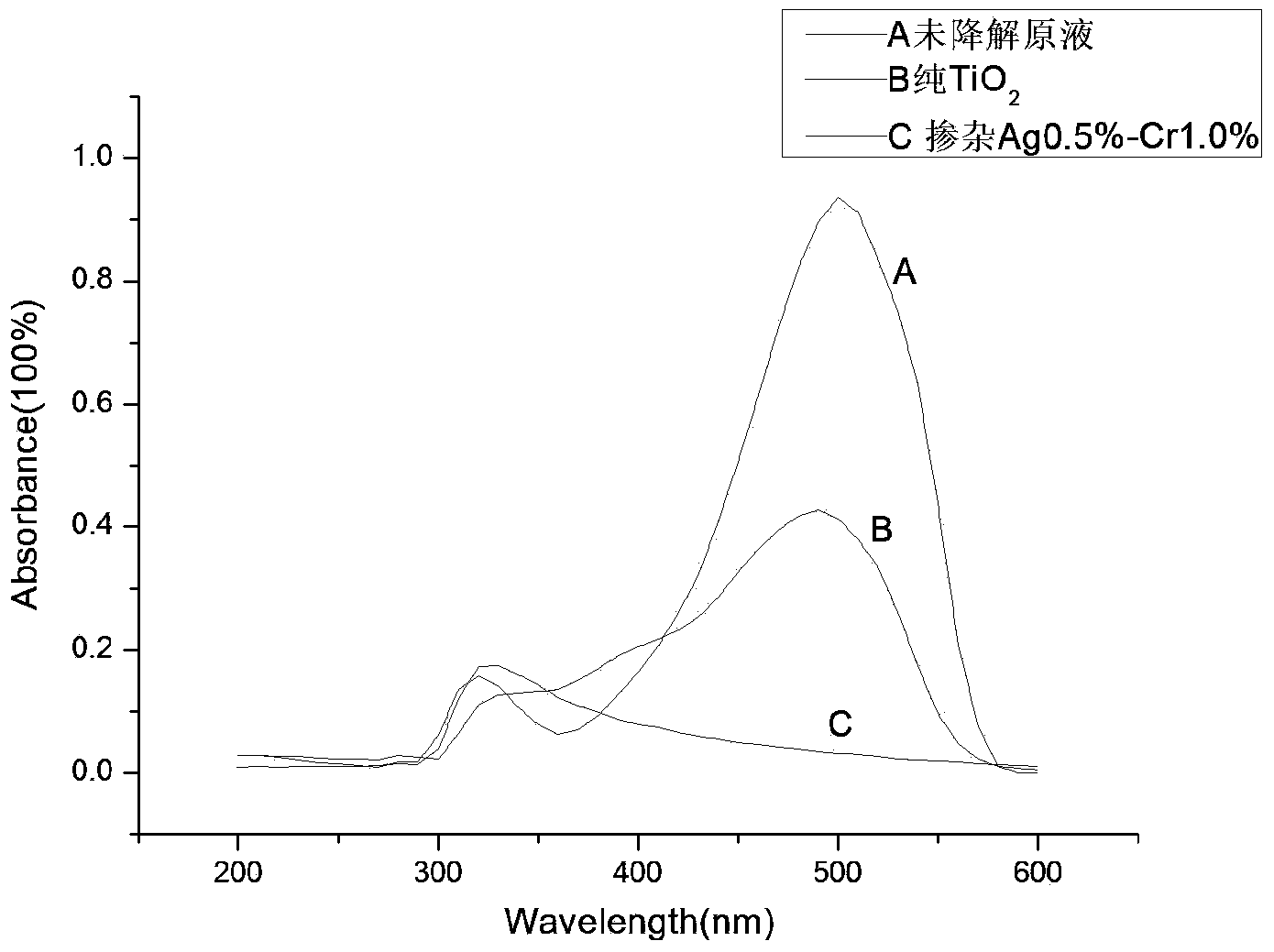

Embodiment 2

[0038] The invention provides a chromium-silver co-doped nano-TiO 2 The preparation method of the photocatalyst adopts the sol-gel method, and the specific operation steps are:

[0039] (1) Add 10mL of butyl titanate to 20mL of absolute ethanol, add dropwise 2mL of glacial acetic acid, and stir magnetically for 30 minutes until uniformly mixed to obtain solution A;

[0040] (2) Dissolve silver nitrate and ferric nitrate in 2mL of distilled water, pour into 20mL of absolute ethanol, add dropwise 2mL of glacial acetic acid, 2mL of dilute nitric acid (concentration 0.1mol / L), stir magnetically for 25 minutes until uniformly mixed, and obtain solution B The amount of silver nitrate added is 0.5% of the molar fraction of the corresponding titanium particles in the solution A obtained in step (1); the added amount of iron nitrate is 1.0% of the molar fraction of the corresponding titanium particles in the solution A obtained in step (1);

[0041] (3) Under the condition of vigorous...

Embodiment 3

[0048] The invention provides a chromium-silver co-doped nano-TiO 2 The preparation method of the photocatalyst adopts the sol-gel method, and the specific operation steps are:

[0049] (1) Add 10mL of butyl titanate to 20mL of absolute ethanol, add dropwise 2mL of glacial acetic acid, and stir magnetically for 30 minutes until uniformly mixed to obtain solution A;

[0050] (2) Dissolve silver nitrate and ferric nitrate in 2mL of distilled water, pour into 20mL of absolute ethanol, add dropwise 2mL of glacial acetic acid, 2mL of dilute nitric acid (concentration 0.1mol / L), stir magnetically for 25 minutes until uniformly mixed, and obtain solution B The amount of silver nitrate added is 1.0% of the molar fraction of the corresponding titanium particles in the solution A obtained in step (1); the added amount of iron nitrate is 2.5% of the molar fraction of the corresponding titanium particles in the solution A obtained in step (1);

[0051] (3) Under the condition of vigorous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com