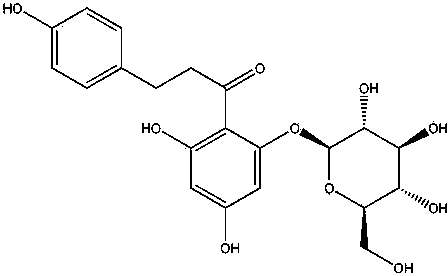

Method for efficiently extracting phlorizin from plants

A phloridzin and high-efficiency technology, applied in the field of medicine, can solve the problems of high equipment requirements, low extraction efficiency, heat-labile components, etc., and achieve the effects of simple process environmental protection, high extraction yield, and low equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

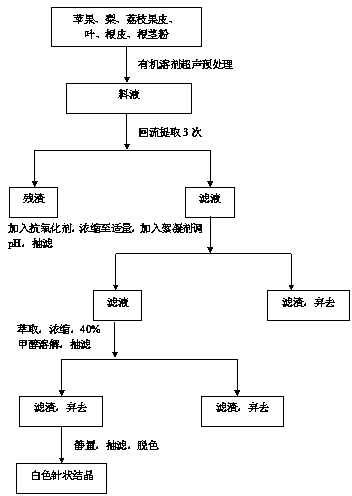

Method used

Image

Examples

Embodiment 1

[0020] Take 1 kg of dried litchi peel powder of 40 mesh, add 5 L of 70% ethanol, conduct ultrasonic treatment at 30 °C for 2 h, then heat and reflux the feed liquid for 3 times for 30 min each time, combine the filtrate, add the total amount of extract to the filtrate 0.2% by weight of antioxidant Vc, distilled under reduced pressure at 60°C until ethanol-free, add 0.5% of the concentrated liquid’s mass of polymerized alumina to the concentrated solution, adjust the pH to 7.5 with 0.3M sodium hydroxide solution, and keep it warm at 60°C 30 min, suction filtration, the filtrate was cooled and extracted 3 times with 1 times the amount of ethyl acetate, the combined extracts were concentrated under reduced pressure to 10:1, then dissolved in 40% methanol, suction filtration, the filtrate was allowed to stand for 24 h, suction Filtrate, dissolve the obtained crystals in water, add activated carbon with 10% of the mass of crystals, stir, filter, let the filtrate stand for 24 hours, ...

Embodiment 2

[0022] Take dried apple branches or leaves and crush them, pass through a 20-mesh sieve, add 10 L of 40% methanol, conduct ultrasonic treatment at 45 °C for 1 h, then heat the feed liquid under reflux and extract 3 times, each time for 1 h, combine the filtrates, and add to the filtrate 0.5% of the total weight of the extract was added to the antioxidant DTT, distilled under reduced pressure at 60°C until there was no ethanol, and 0.7% of the concentrated solution was added to the concentrated solution. Adjust the pH to 7.5 with 0.3M sodium hydroxide solution. Keep warm at 60°C for 30 min, filter with suction, extract the filtrate three times with 1 times the amount of ethyl acetate after cooling, combine the extracts, concentrate under reduced pressure to 10:1, dissolve with 40% methanol, filter with suction, and statically Set aside for 24 h, filter with suction, dissolve the obtained crystals in water, add activated carbon with 10% of the mass of the crystals, stir, filter, ...

Embodiment 3

[0024] The dried pear branches or leaves were crushed, passed through a 20-mesh sieve, 15 L of 40% ethanol was added, ultrasonic treatment was performed at 70 °C for 30 min, and then the material liquid was heated and refluxed for 3 times, each time for 2 h, the filtrate was combined and poured into the filtrate. Add 0.3% of the total weight of the extract to the antioxidant DTT, distill under reduced pressure at 80°C until there is no ethanol, add tartaric acid with a mass of 1% of the concentrate to the concentrated solution, adjust the pH to 7.5 with 0.3M sodium hydroxide solution, and set the temperature at 60°C Keep warm for 30 min, filter with suction, extract the filtrate with 1 times the amount of ethyl acetate three times after cooling, combine the extracts, concentrate under reduced pressure to 10:1, dissolve with 40% methanol, filter with suction, and let the filtrate stand for 24 h , suction filtration, the obtained crystals were dissolved in water, activated carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com