A black weather-resistant polyethylene insulating material for overhead cables and its preparation method

A polyethylene insulating material, overhead cable technology, applied in insulators, circuits, electrical components, etc., can solve problems such as limitations, and achieve the effects of improving uniformity, tight integration, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

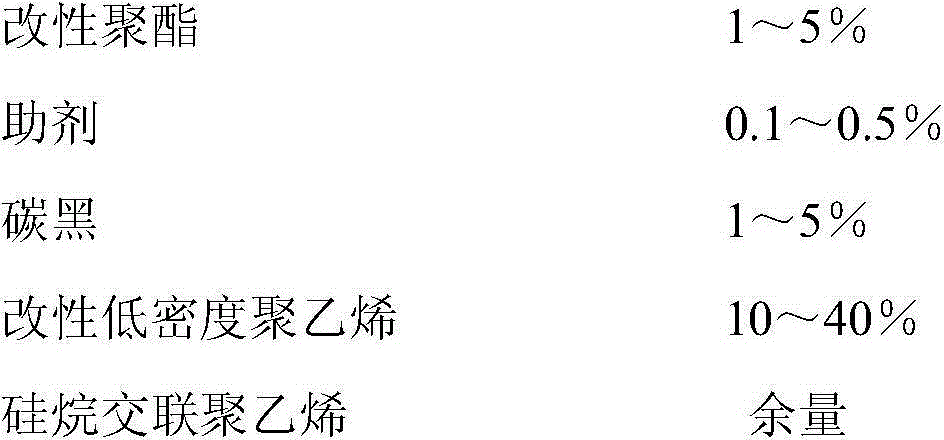

[0055] A black weather-resistant polyethylene insulating material for overhead cables, characterized in that the mass percentage of the raw materials is:

[0056]

[0057] The preparation method of described modified polyester, its concrete steps are:

[0058](1) Disperse inorganic particles under the condition that alcohol is a solvent, and the alcohol solution is ethanol, methanol or isopropanol solution; then under alkaline conditions, add aminotriethoxysilane, and carry out centrifugation after the reaction, to The solid is vacuum-dried to obtain surface-functionalized inorganic particles;

[0059] The concentration of the inorganic particles in the alcohol solution is 5-35kg / m 3 , the pH of the system is controlled to be 8.5 to 9.5, the reaction temperature is 60 to 75 °C, and the reaction time is 150 to 240 min;

[0060] The inorganic particles are nanometer indium tin oxide, nanometer indium antimony oxide and nanometer zinc oxide, the mass ratio of the three is 1:...

Embodiment 2

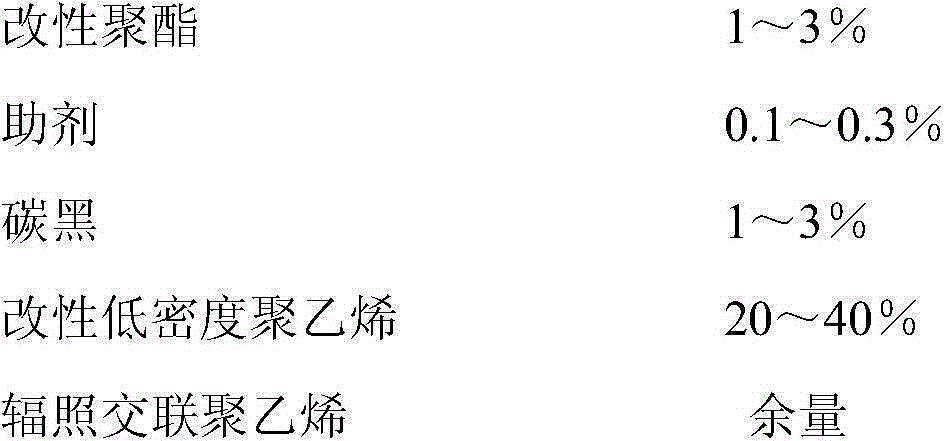

[0076] A black weather-resistant polyethylene insulating material for overhead cables, characterized in that the mass percentage of the raw materials is:

[0077]

[0078]

[0079] The preparation method of described modified polyester, its concrete steps are:

[0080] (1) Disperse inorganic particles under the condition that alcohol is a solvent, and the alcohol solution is ethanol, methanol or isopropanol solution; then under alkaline conditions, add aminotriethoxysilane, and carry out centrifugation after the reaction, to The solid is vacuum-dried to obtain surface-functionalized inorganic particles;

[0081] The concentration of the inorganic particles in the alcohol solution is 5-35kg / m 3 , the pH of the system is controlled to be 8.5 to 9.5, the reaction temperature is 60 to 75 °C, and the reaction time is 150 to 240 min;

[0082] The inorganic particles are nanometer indium tin oxide, nanometer indium antimony oxide and nanometer zinc oxide, the mass ratio of th...

Embodiment 3

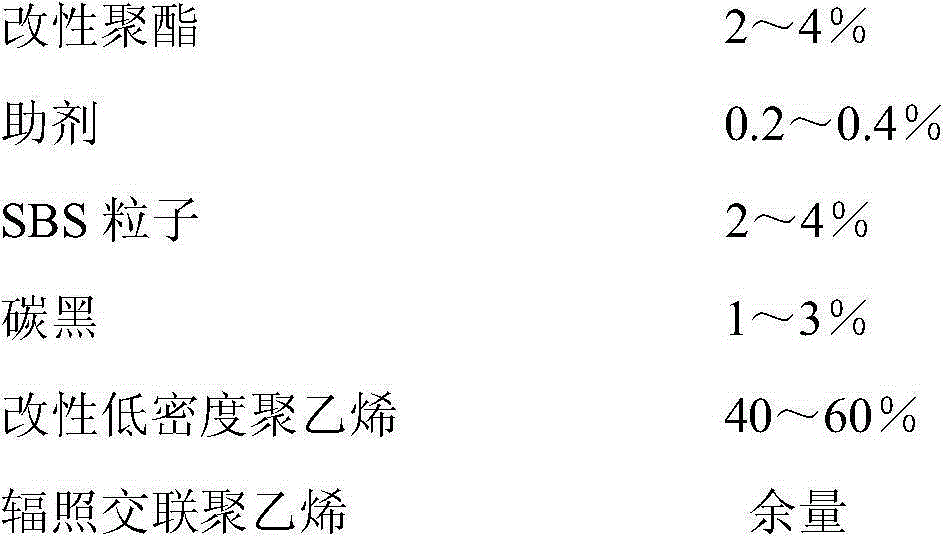

[0100] A black weather-resistant polyethylene insulating material for overhead cables, characterized in that the mass percentage of the raw materials is:

[0101]

[0102] The preparation method of described modified polyester, its concrete steps are:

[0103] (1) Disperse inorganic particles under the condition that alcohol is a solvent, and the alcohol solution is ethanol, methanol or isopropanol solution; then under alkaline conditions, add aminotriethoxysilane, and carry out centrifugation after the reaction, to The solid is vacuum-dried to obtain surface-functionalized inorganic particles;

[0104] The concentration of the inorganic particles in the alcohol solution is 5-35kg / m 3 , the pH of the system is controlled to be 8.5 to 9.5, the reaction temperature is 60 to 75 °C, and the reaction time is 150 to 240 min;

[0105] The inorganic particles are nanometer indium tin oxide, nanometer indium antimony oxide and nanometer zinc oxide, the mass ratio of the three is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com