A kind of polyester plastic for cable and preparation method thereof

A polyester plastic and cable technology, applied in the field of power materials, can solve problems such as limitations, and achieve the effects of easy large-scale production, tight integration, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

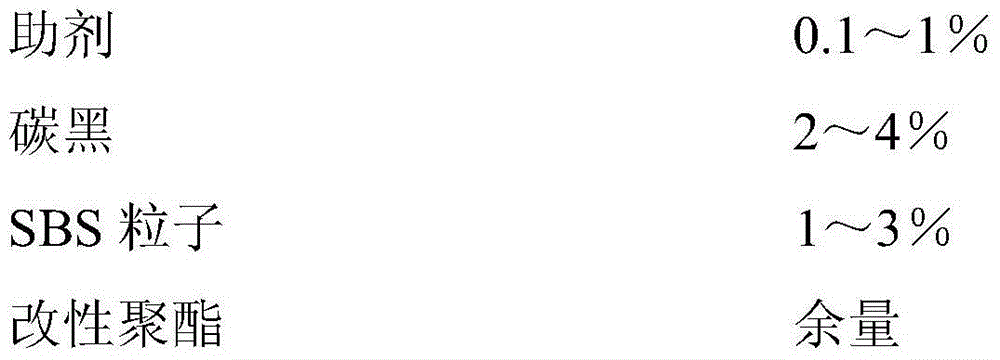

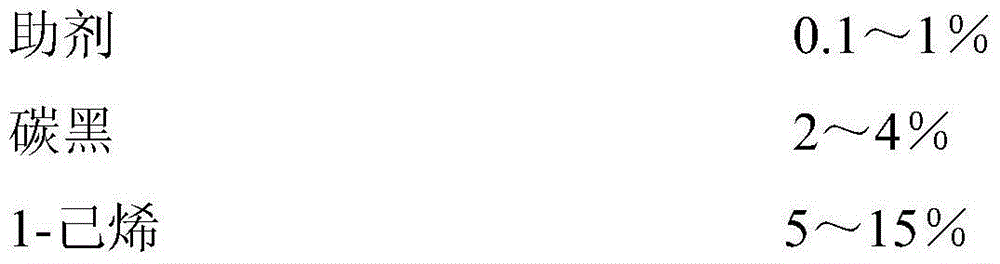

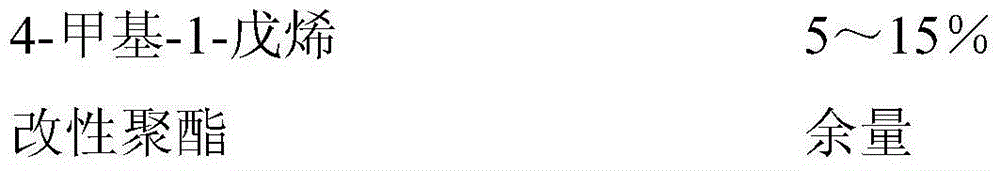

[0047] A kind of polyester plastics for electric cable, it is characterized in that, the mass percent of its raw material is:

[0048] Auxiliary 0.1%

[0049] Masterbatch 2%

[0050] Modified polyester 97.9%

[0051] The preparation method of described modified polyester, its concrete steps are:

[0052] (1) Dispersing inorganic particles under the condition of ethanol as a solvent; then adding aminopropyltrimethoxysilane under alkaline conditions, performing centrifugation after the reaction, and vacuum drying the solid to prepare surface functionalized inorganic particles;

[0053] The concentration of the inorganic particles in the alcohol solution is 1-20kg / m 3 , the pH of the system is controlled at 8.5-9.5, the reaction temperature is 60-75°C, and the reaction time is 150-240min;

[0054] The inorganic particles are nano-indium tin oxide, nano-indium antimony oxide and nano-titanium dioxide particles, the mass ratio of the three is 1:2:3, the average particle size is...

Embodiment 2

[0063] A kind of polyester plastics for electric cable, it is characterized in that, the mass percent of its raw material is:

[0064] Auxiliary 0.5%

[0065] Masterbatch 3%

[0066] Modified polyester 96.5%

[0067] The preparation method of described modified polyester, its concrete steps are:

[0068] (1) Dispersing inorganic particles under the condition of ethanol as a solvent; then adding aminopropyltrimethoxysilane under alkaline conditions, performing centrifugation after the reaction, and vacuum drying the solid to prepare surface functionalized inorganic particles;

[0069] The concentration of the inorganic particles in the alcohol solution is 1-20kg / m 3 , the pH of the system is controlled at 8.5-9.5, the reaction temperature is 60-75°C, and the reaction time is 150-240min;

[0070] The inorganic particles are nano-indium tin oxide, nano-indium antimony oxide and nano-titanium dioxide particles, the mass ratio of the three is 1:2:3, the average particle size is 1...

Embodiment 3

[0079] A kind of polyester plastics for electric cable, it is characterized in that, the mass percent of its raw material is:

[0080] Auxiliary 1%

[0081] Masterbatch 4%

[0082] Modified polyester 95%

[0083] The preparation method of described modified polyester, its concrete steps are:

[0084] (1) Dispersing inorganic particles under the condition of ethanol as a solvent; then adding aminopropyltrimethoxysilane under alkaline conditions, performing centrifugation after the reaction, and vacuum drying the solid to prepare surface functionalized inorganic particles;

[0085] The concentration of the inorganic particles in the alcohol solution is 1-20kg / m 3 , the pH of the system is controlled at 8.5-9.5, the reaction temperature is 60-75°C, and the reaction time is 150-240min;

[0086] The inorganic particles are nano-indium tin oxide, nano-indium antimony oxide and nano-titanium dioxide particles, the mass ratio of the three is 1:2:3, the average particle size is 10-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com