Narrow-particle size distribution extra-coarse cemented carbide and preparation method thereof

A technology of narrow particle size distribution and cemented carbide, which is applied in the field of ultra-coarse cemented carbide with narrow particle size distribution and its preparation, can solve the problems of easy pollution of the environment, difficulty in obtaining high-performance ultra-coarse cemented carbide, and wide particle size distribution. Uniform particle size distribution, good thermal fatigue resistance, and uniform distribution of bonding phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of the ultra-coarse-grained cemented carbide with narrow particle size distribution of the present invention comprises the following steps:

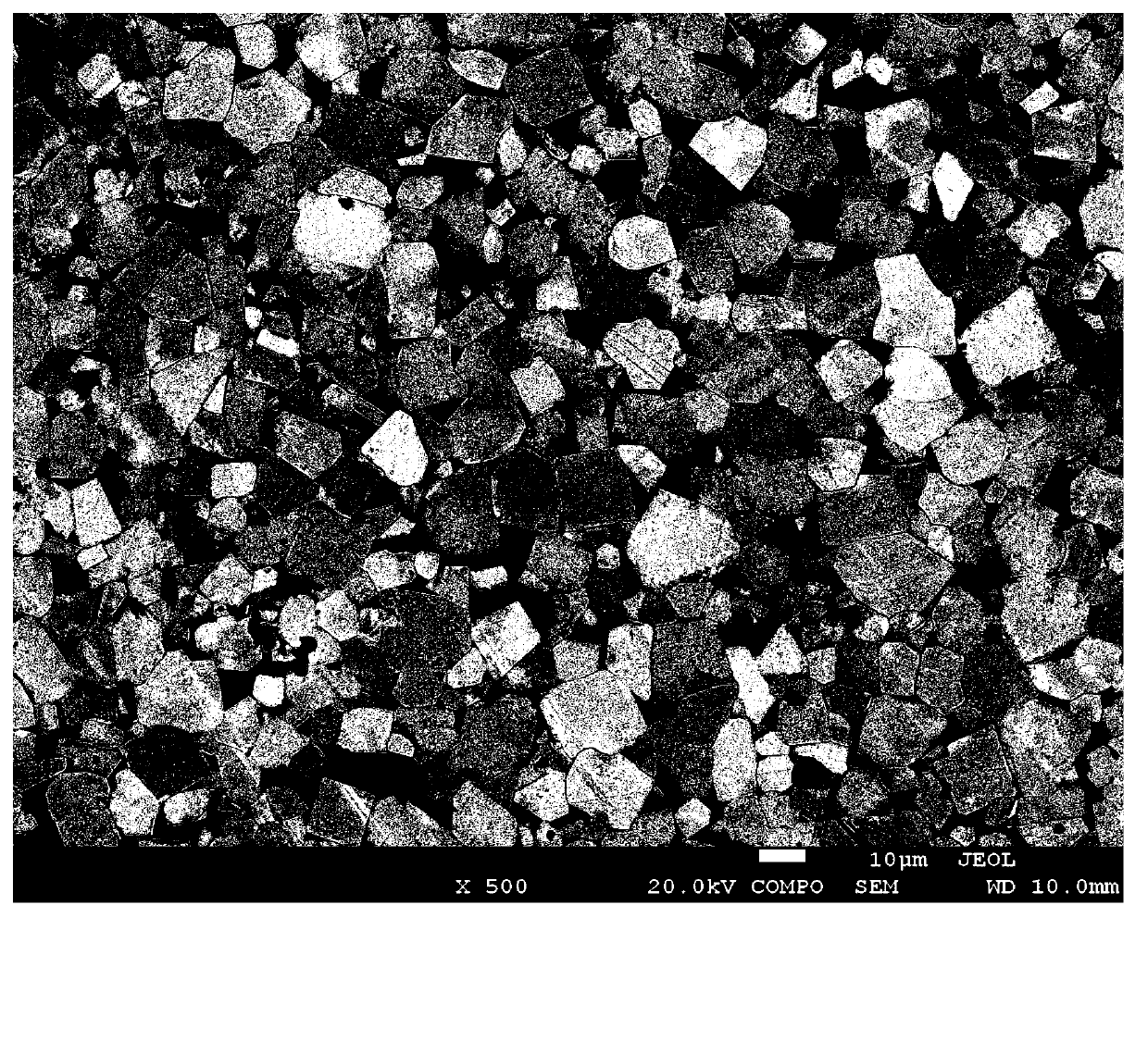

[0021] 1) Breaking of hard aggregates of ultra-coarse tungsten carbide powder: put ultra-coarse tungsten carbide powder with a Fischer particle size of 20 μm or more into a stirring ball mill or rolling ball mill, and perform ball milling to break the "hard aggregates" of WC powder.

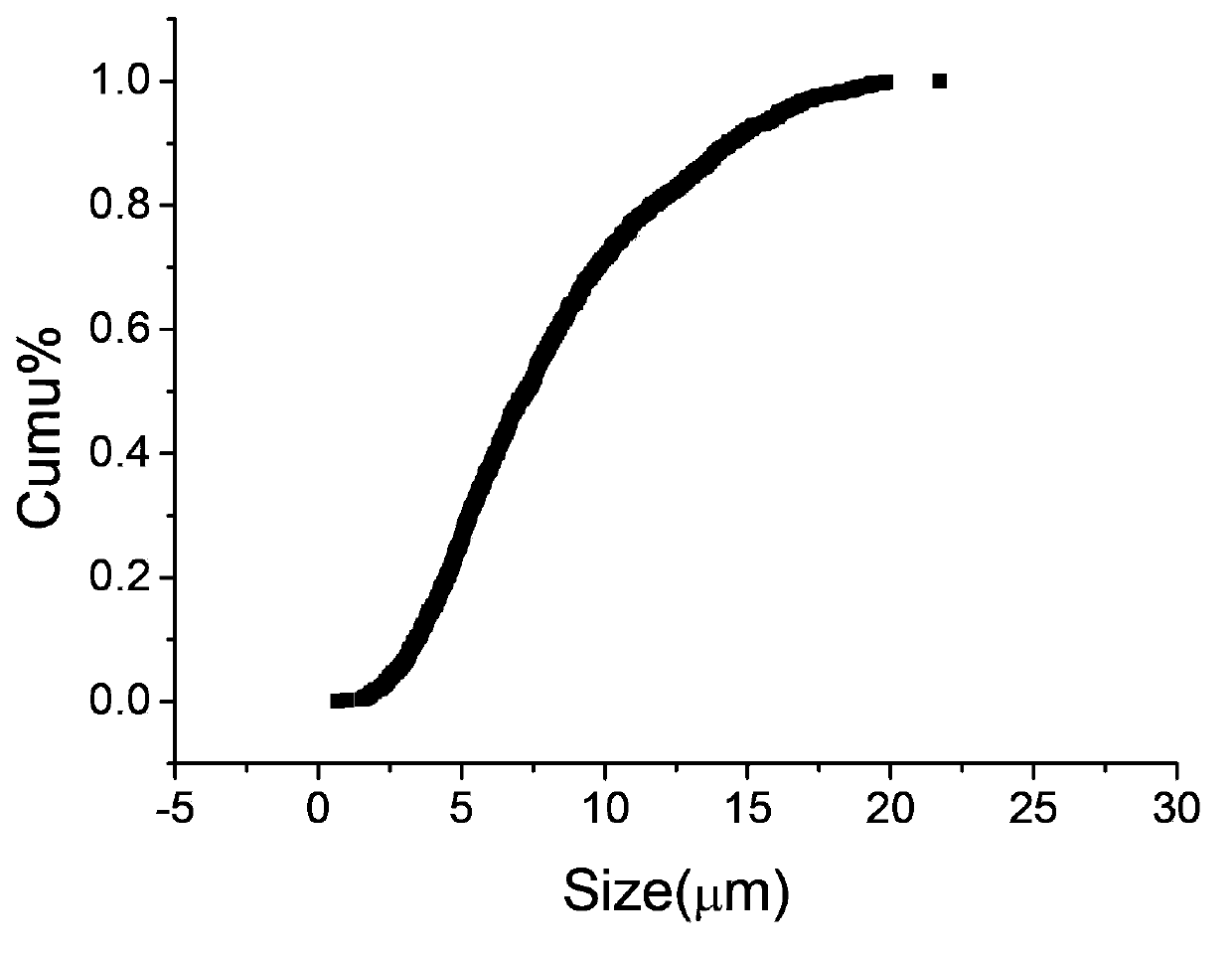

[0022] 2) Particle size classification of tungsten carbide powder: the ultra-coarse tungsten carbide powder crushed by the ball mill is classified by airflow classification or passing through a vibrating sieve to remove finer and particularly coarse tungsten carbide powder particles, and obtain the average particle size required for subsequent processes. Ultra-coarse tungsten carbide powder in particle size and particle size distribution.

[0023] 3) Cobalt coating by magnetron sputtering of tungsten carbide powder: put the gra...

Embodiment 1

[0029] The WC powder with a Fsss particle size of 20 μm and a carbon content of 6.17% was ball milled in a rolling ball mill for 16 hours to deagglomerate, with a ball-to-material ratio of 3:1; then air classification to remove finer and particularly coarse tungsten carbide powder particles, Obtain 90wt% tungsten carbide powder with a narrow particle size distribution of tungsten carbide powder with a particle size between 3.5 μm and 14 μm; put the tungsten carbide powder into a magnetron sputtering coating machine for cobalt plating, and increase the quality of the powder by 1% by cobalt plating ;The cobalt-coated WC, paraffin wax and 5wt% cobalt powder were wet-mixed in a rolling ball mill, and a small amount of cemented carbide grinding balls were added during the wet-mixing. The ball-to-material ratio was 1:1, and the wet-mixing time was 36 hours; Finally, dry in a vacuum oven at 80°C to remove alcohol and pass through a 80-mesh sieve, then mold the powder at 200 MPa. The ...

Embodiment 2

[0032]The WC powder with a Fsss particle size of 30 μm and a carbon content of 6.16% was ball milled in a stirring mill for 4 hours to deagglomerate, and the ball-to-material ratio was 3:1; then air classification was performed to remove finer and particularly coarse tungsten carbide particles, Obtain 90wt% tungsten carbide powder with a narrow particle size distribution of tungsten carbide powder with a particle size between 6 μm and 24 μm; then put the tungsten carbide powder into a magnetron sputtering coating machine for cobalt plating, and increase the quality of the powder by 2% by cobalt plating ;The cobalt-coated WC, PEG and 12wt% cobalt powder are wet-mixed in a rolling ball mill, and a small amount of cemented carbide grinding balls are added during the wet-mixing. The ball-to-material ratio is 1:5, and the wet-mixing time is 16 hours; mix well After that, the alcohol was removed by spray drying, and then the powder was isostatically pressed at 200MPa. The product is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com