Ceramic quenched and tempered steel and preparation method thereof

A technology of ceramics and molten steel, applied in the field of ceramic quenched and tempered steel and its preparation, can solve the problem of high cost and achieve the effect of not being prone to fatigue cracks, high strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

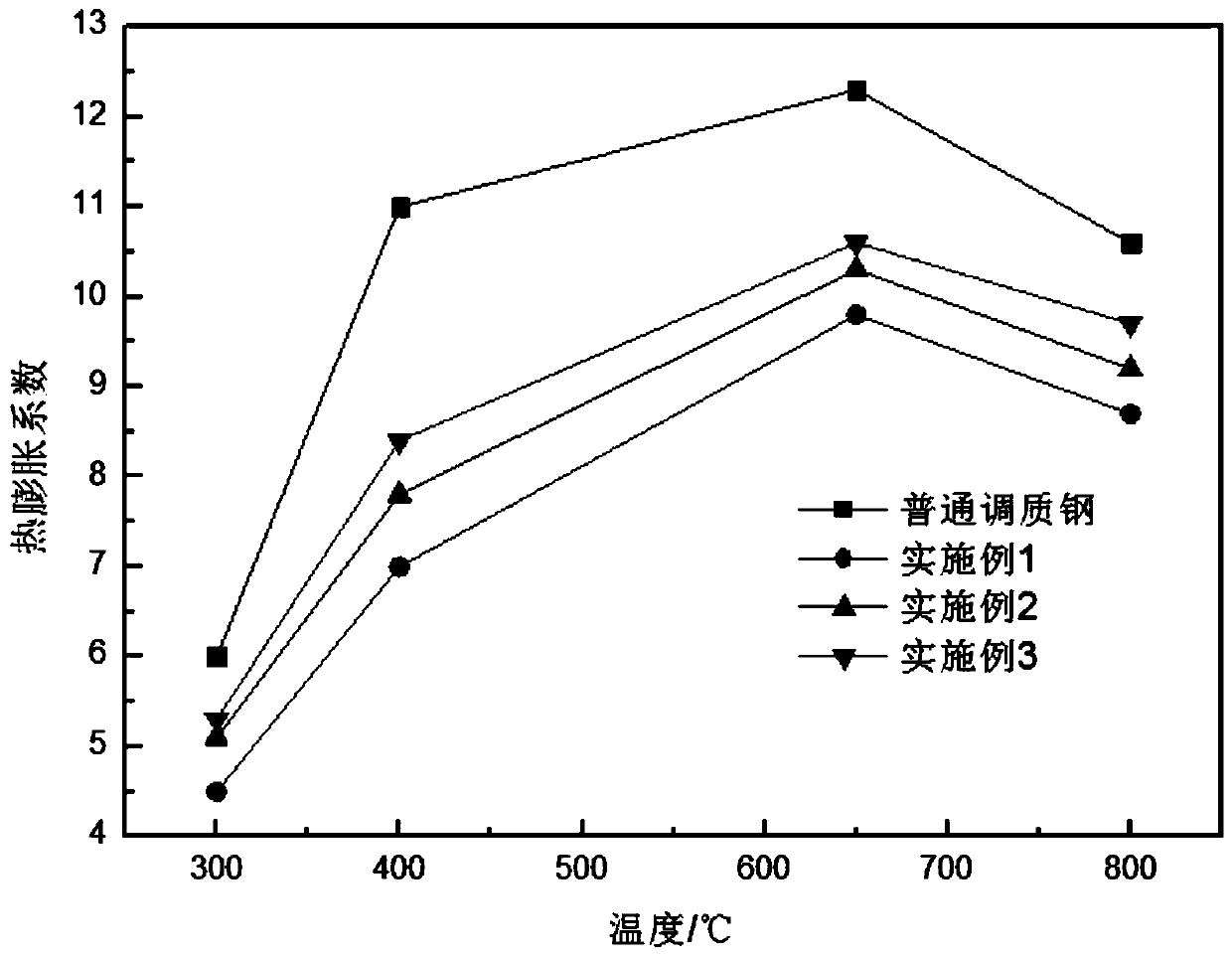

Examples

Embodiment 1

[0035] A kind of ceramic modulation steel, including the following raw materials in weight percentage: scrap steel (not limited by materials) 71.5%, kaolin 3%, bauxite 5%, quartz sand 5%, mica (series) 1%, bentonite 1%, blue 1% spar, 1% barite, 1% calcite, 1% graphite, 1% fluorite, 1% feldspar, 1% mullite, 1% SiC, 1% zeolite, 1% wollastonite, spinel Stone 1%, crystal stone 1.5%, bauxite 1%.

[0036] The preparation method of the ceramic modulated steel comprises the following steps:

[0037] (1) Add the raw materials in formula quantities other than scrap steel into the intermediate frequency electric furnace or electric arc furnace, and add scrap steel one after another as the raw materials continue to melt; and add covering agent or slagging agent during the melting process to avoid steel The liquid is directly in contact with the air; metals that are difficult to melt and are not easy to oxidize or burn are put into the bottom of the crucible, and small pieces of scrap ste...

Embodiment 2

[0048] A kind of ceramic modulation steel, including the following raw materials in weight percentage: scrap steel (not limited by material) 70%, kaolin 3%, bauxite 3%, quartz sand 4%, mica (series) 2%, bentonite 2%, blue 1% spar, 1% barite, 1% calcite, 1% graphite, 2% fluorite, 1% feldspar, 2% mullite, 1% SiC, 1% zeolite, 1% wollastonite, spinel Stone 1%, crystal stone 1%, bauxite 2%.

[0049] The preparation method of the ceramic modulated steel comprises the following steps:

[0050] (1) Add the raw materials in formula quantities other than scrap steel into the intermediate frequency electric furnace or electric arc furnace, and add scrap steel one after another as the raw materials continue to melt; and add covering agent or slagging agent during the melting process to avoid steel The liquid is directly in contact with the air; metals that are difficult to melt and are not easy to oxidize or burn are put into the bottom of the crucible, and small pieces of scrap steel ar...

Embodiment 3

[0061] A kind of ceramic modulation steel, including raw materials in the following weight percentages: scrap steel (not limited by materials) 72%, kaolin 2%, bauxite 3%, quartz sand 5%, mica (series) 1%, kyanite 1% , barite 1%, calcite 1%, fluorite 1%, feldspar 1%, mullite 1%, SiC 1%, zeolite 1%, wollastonite 3%, spinel 1%, bentonite 1%, Graphite 1%, crystal stone 1%, bauxite 2%.

[0062] The preparation method of the ceramic modulated steel comprises the following steps:

[0063] (1) Add the raw materials in formula quantities other than scrap steel into the intermediate frequency electric furnace or electric arc furnace, and add scrap steel one after another as the raw materials continue to melt; and add covering agent or slagging agent during the melting process to avoid steel The liquid is directly in contact with the air; metals that are difficult to melt and are not easy to oxidize or burn are put into the bottom of the crucible, and small pieces of scrap steel are add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com