Organic electroluminescence device and preparing method thereof

An electroluminescent device and luminescence technology, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as hole and electron imbalance, reduce device turn-on voltage, and affect device stability. Achieve the effects of reducing void ratio, improving injection capacity and prolonging working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

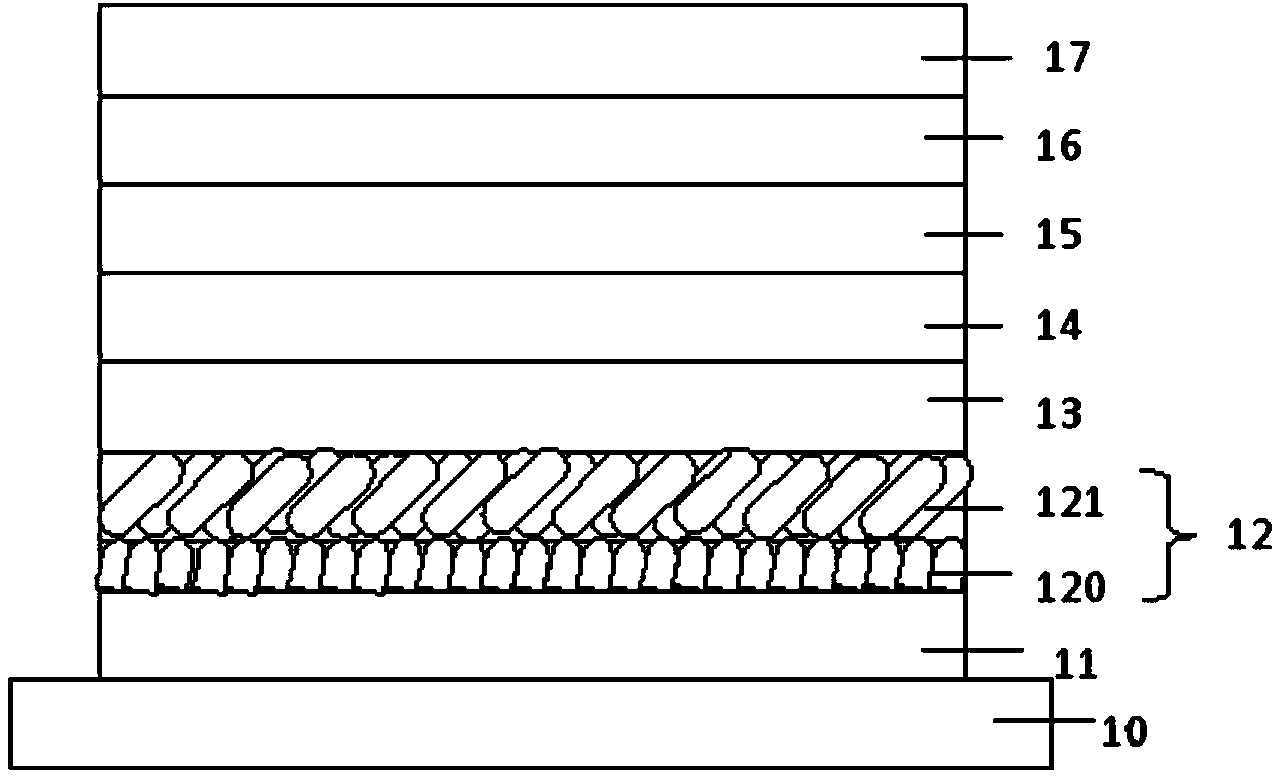

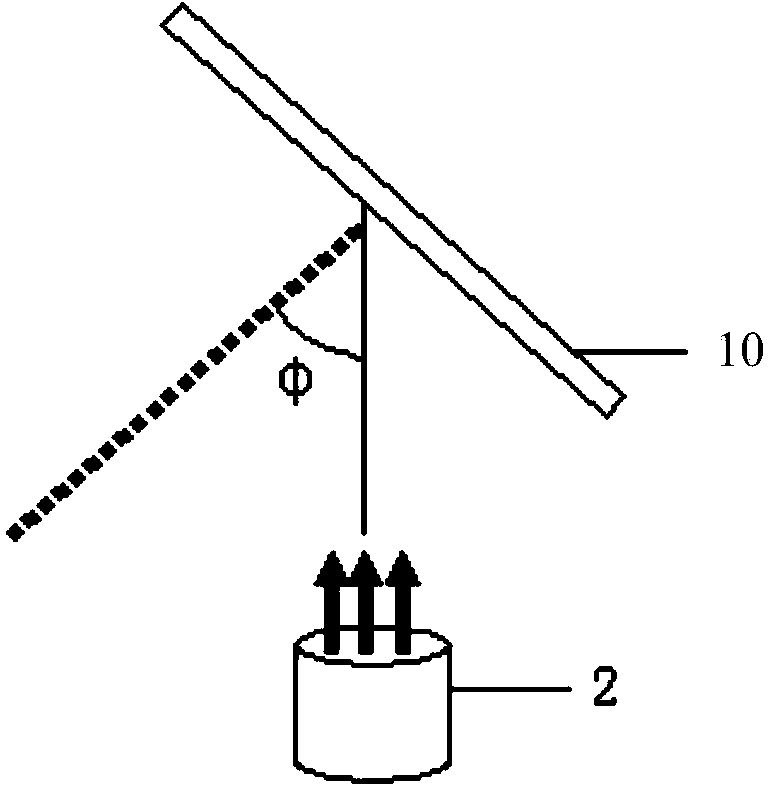

[0022] Such as figure 1 As shown, the organic electroluminescent device in this embodiment includes a substrate 10, a first electrode 11, a hole injection layer 12, a hole transport layer 13, an organic light-emitting layer 14, an electron transport layer 15, and an electron injection layer stacked in sequence. 16 and the second electrode 17, the hole injection layer 12 is formed by stacking the first layer of inorganic nano-column film 120 and the second layer of inorganic nano-column film 121, wherein the inclination angle of the inorganic nano-column of the inorganic nano-column film 120 is smaller than that of the inorganic nano-column film. The inclination angle of the inorganic nanocolumns of the nanocolumn thin film 121 , the inclination angle refers to the included angle between the axial direction of the inorganic nanocolumns and the normal direction of the substrate 10 .

[0023] The inclination angle of the inorganic nanocolumns is generally achieved by evaporation,...

Embodiment 2

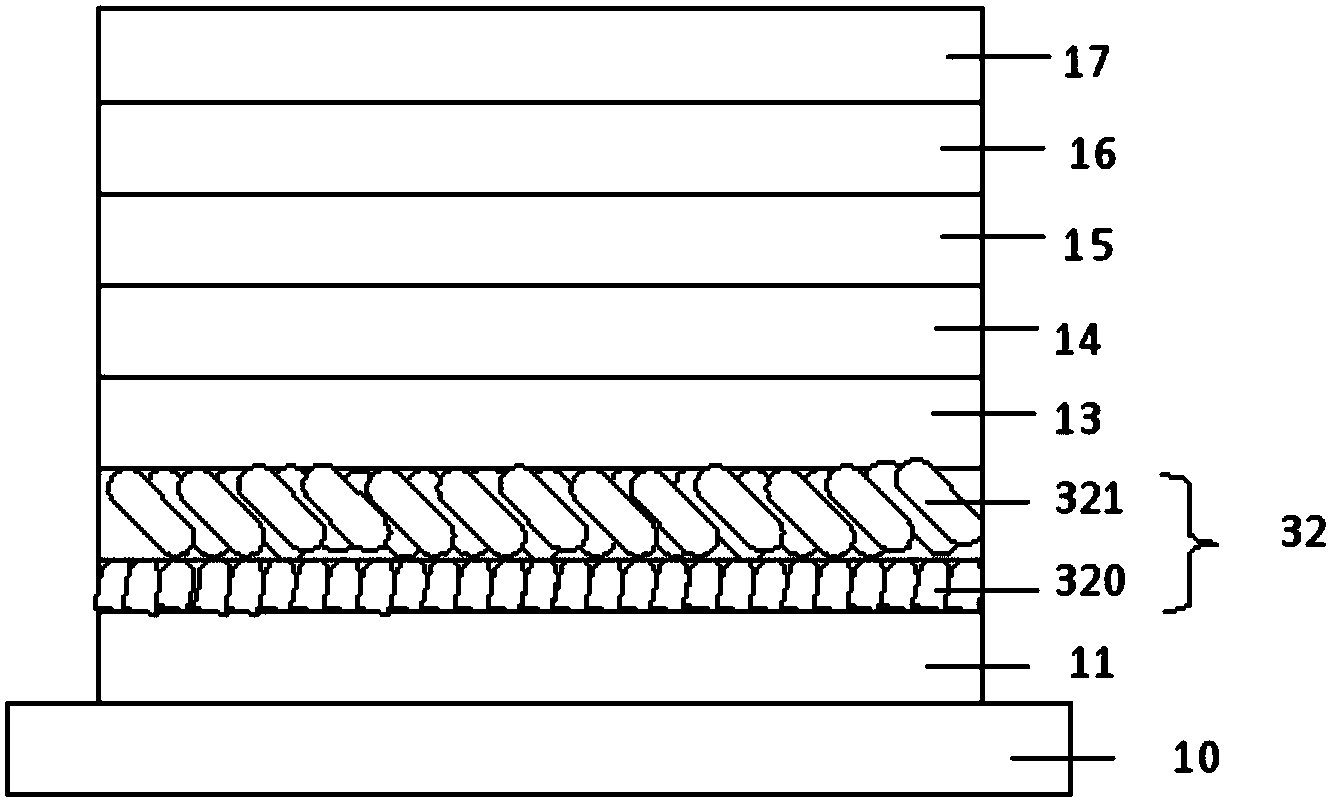

[0034] Such as image 3 As shown, the structure of the organic electroluminescent device in this embodiment is consistent with the structure of the organic electroluminescent device in embodiment 1, the difference is that the first layer of inorganic nanocolumn thin film 120 constituting the hole injection layer 12 The growth angle range of the inorganic nanocolumns is 10-30°, and the growth angle range of the inorganic nanocolumns of the second layer of inorganic nanocolumn film 121 is -45~-85°

Embodiment 3

[0036] The structure of the organic electroluminescent device in this embodiment is consistent with the structure of the organic electroluminescent device in Embodiment 1, the difference is that the inorganic nanocolumn thin film 120 of the first layer of the hole injection layer 12 consists of inorganic nano The growth angle of the pillars ranges from -10° to -30°, and the growth angle of the inorganic nanopillars of the second inorganic nanopillar thin film 121 ranges from 45° to 85°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com