Novel LTCC double-layer single-feed circular polarization micro-strip patch array antenna

A microstrip patch and array antenna technology, which is applied to antenna unit combinations, antennas, slot antennas and other directions with different polarization directions, can solve the problem of high requirements on the dimensional accuracy of the patch cut angle, increasing the complexity of the antenna structure, and disadvantageous antennas. Miniaturization and other issues, to achieve the effect of more size, simple structure and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below with reference to the drawings and examples, but the embodiments of the present invention are not limited thereto.

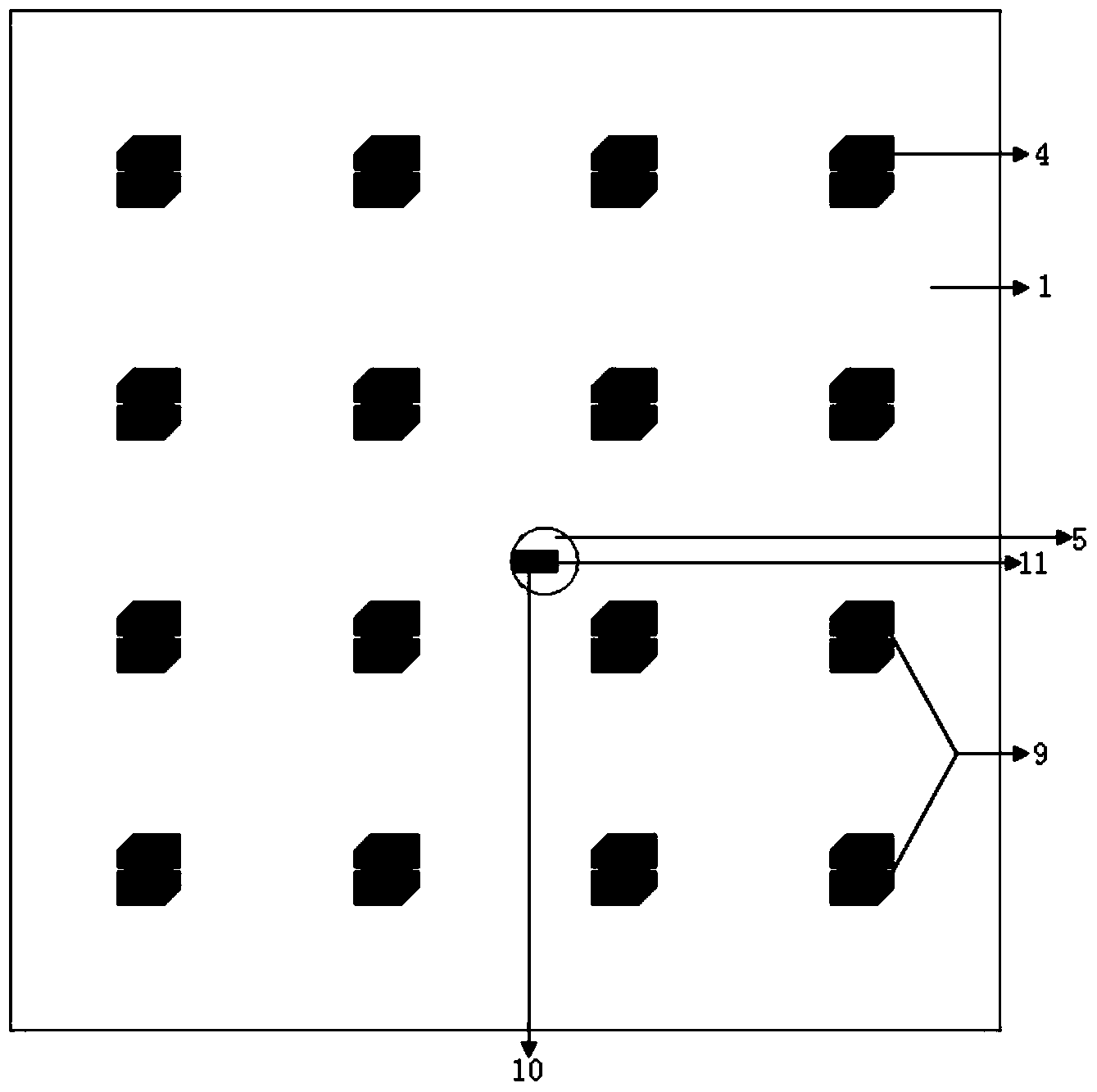

[0029] The center frequency point of the microstrip patch array antenna provided in this embodiment is 10GHz, such as Figure 6 As shown, the present invention can realize a microstrip patch array antenna with an impedance bandwidth of 1.5 GHz and a maximum gain of more than 16.7 dB within a section thickness of 2 mm, and the axial ratio of the antenna can be less than 1.5 dB.

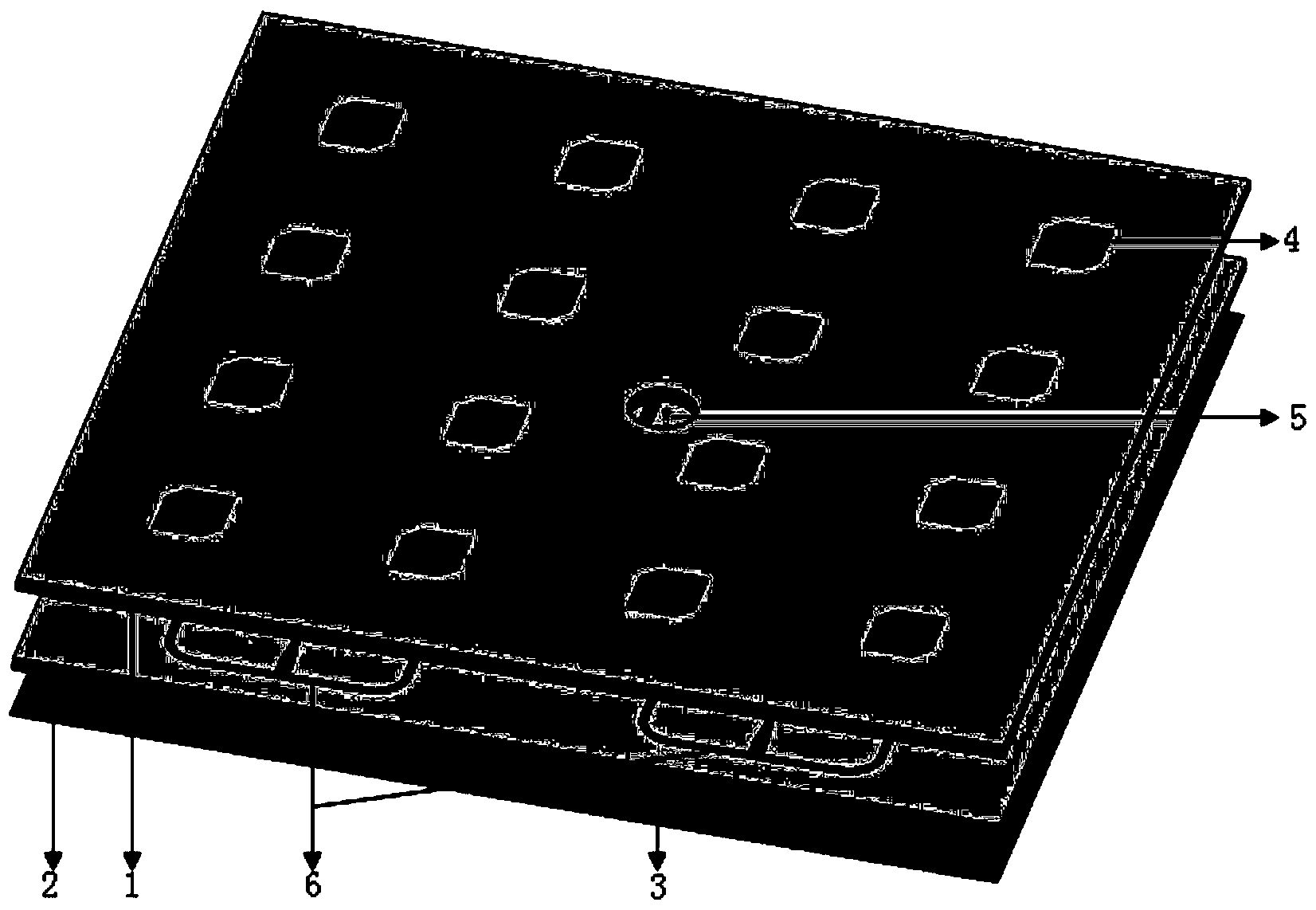

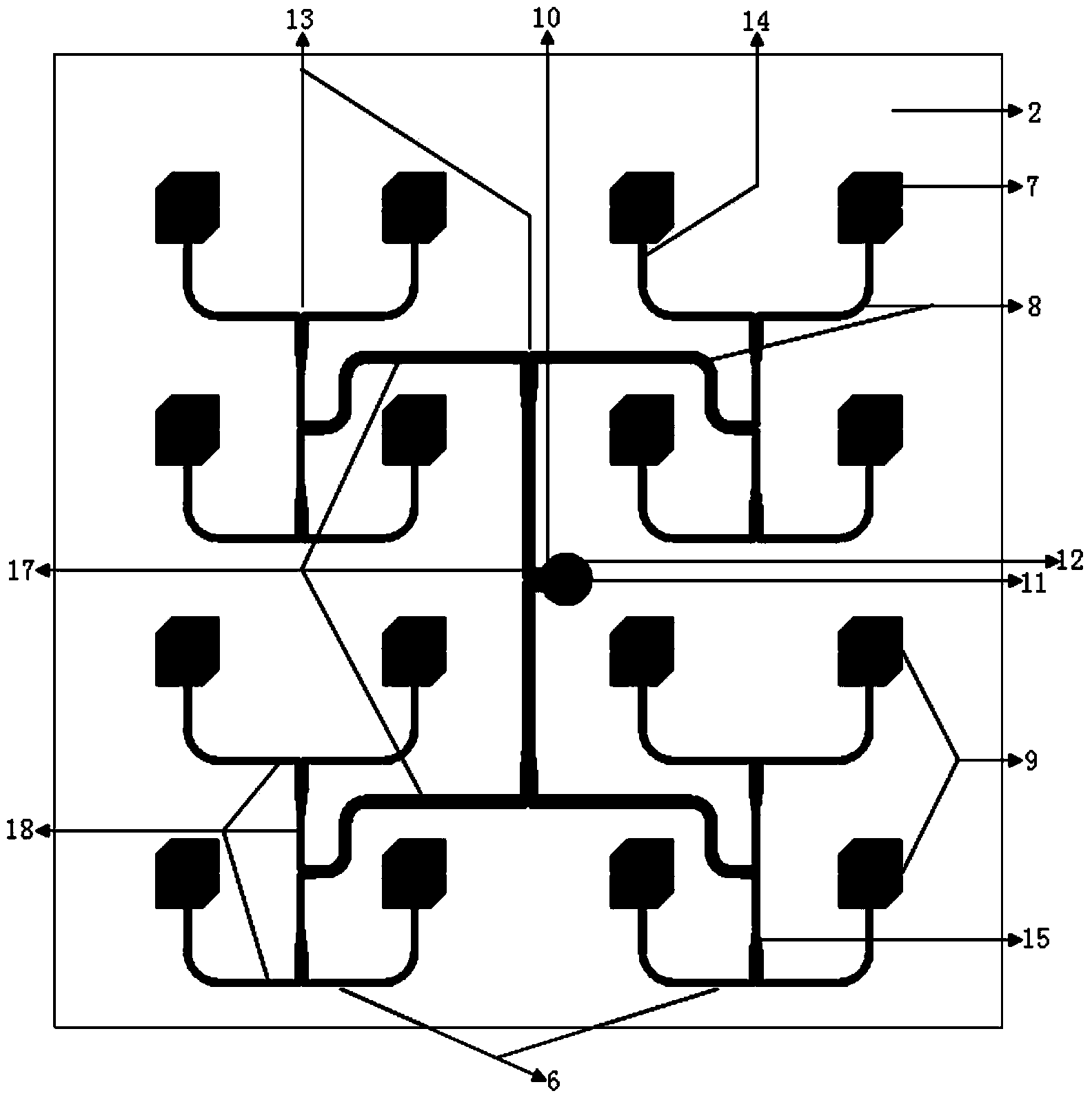

[0030] An LTCC double-layer single-feed circularly polarized microstrip patch array antenna provided in this embodiment includes:

[0031] Upper LTCC substrate 1: The substrate is laminated with 10 LTCC cast films with a thickness of 0.1mm and a dielectric constant of 5.9. The lateral dimension of the substrate is 74.2mm and the longitudinal dimension is 76.3mm. The upper surface of the substrate is printed with silv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com