Terahertz pulse intensity device

A technology of terahertz pulse and intensity, applied in the field of terahertz technology, can solve problems such as the decline of terahertz wave efficiency, and achieve the effect of wide application range and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

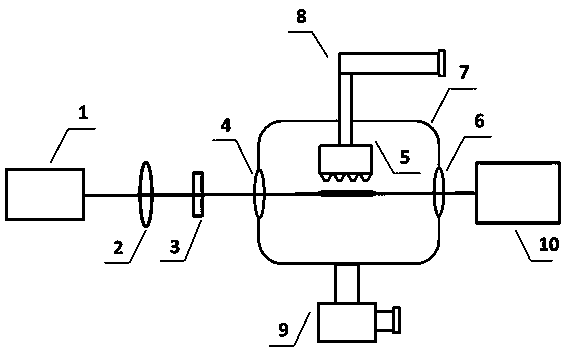

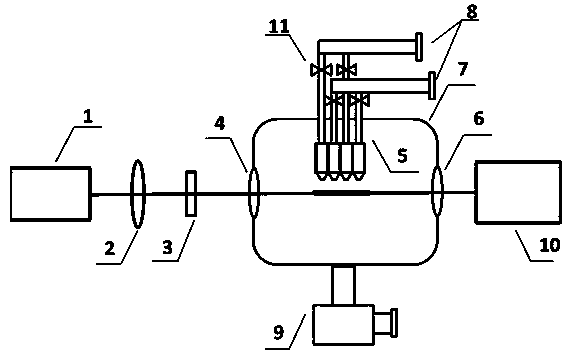

[0011] Such as figure 1 The schematic diagram of the device structure of the terahertz pulse intensity is shown. The device includes a femtosecond laser 1, a focusing lens 2, a frequency doubling crystal 3, a vacuum chamber entrance window 4, a gas nozzle group 5, a vacuum chamber exit window 6, a vacuum chamber 7, Gas pipeline 8, vacuum pump 9 and terahertz detection system 10. The pump laser light emitted from the femtosecond laser 1 passes through the focusing lens 2 and the frequency doubling crystal 3 in turn to form a two-color field light source. The two-color field light source enters the vacuum chamber 7 after passing through the vacuum chamber incident window 4, and is focused in the vacuum chamber 7. Plasma drawing is formed near the focal point of the focusing lens 2, the gas inlet of the gas pipeline 8 is placed outside the vacuum chamber 7, and the gas outlet of the gas pipeline 8 communicates with the variable-structure gas nozzle group 5 placed in the vacuum ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com