Heat-curable silicone resin sheet having phosphor-containing layer and white pigment-containing layer, method of producing light emitting device using same and encapsulated light emitting semiconductor device produced thereby

A silicone resin, thermosetting technology, applied in the direction of semiconductor devices, chemical instruments and methods, transportation and packaging, etc., can solve the problems of high brightness, glare, etc., and achieve stability over time, good usability, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0191]The composition (2) used in the preparation of the silicone resin sheet of the present invention is obtained by uniformly mixing the components (A) to (D) and optional components blended as necessary, and the composition (1) by Components (E), (F), (C), and (G) and optional components blended as needed are uniformly mixed for further preparation. Usually, the two liquids are stored separately so that solidification does not occur, and the two liquids are mixed at the time of use, and then transferred to the next step. Of course, reaction inhibitors such as the acetylenic alcohols may be added in a small amount to be used as a single solution.

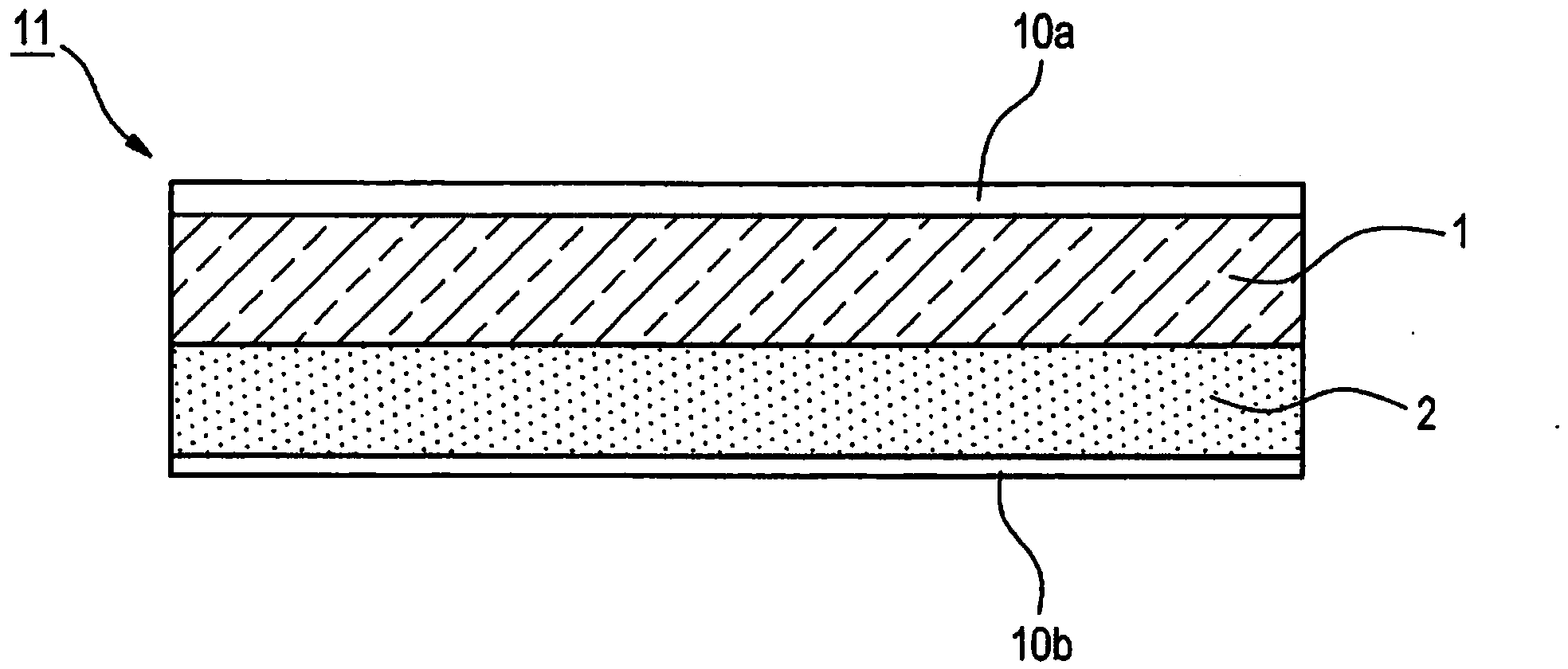

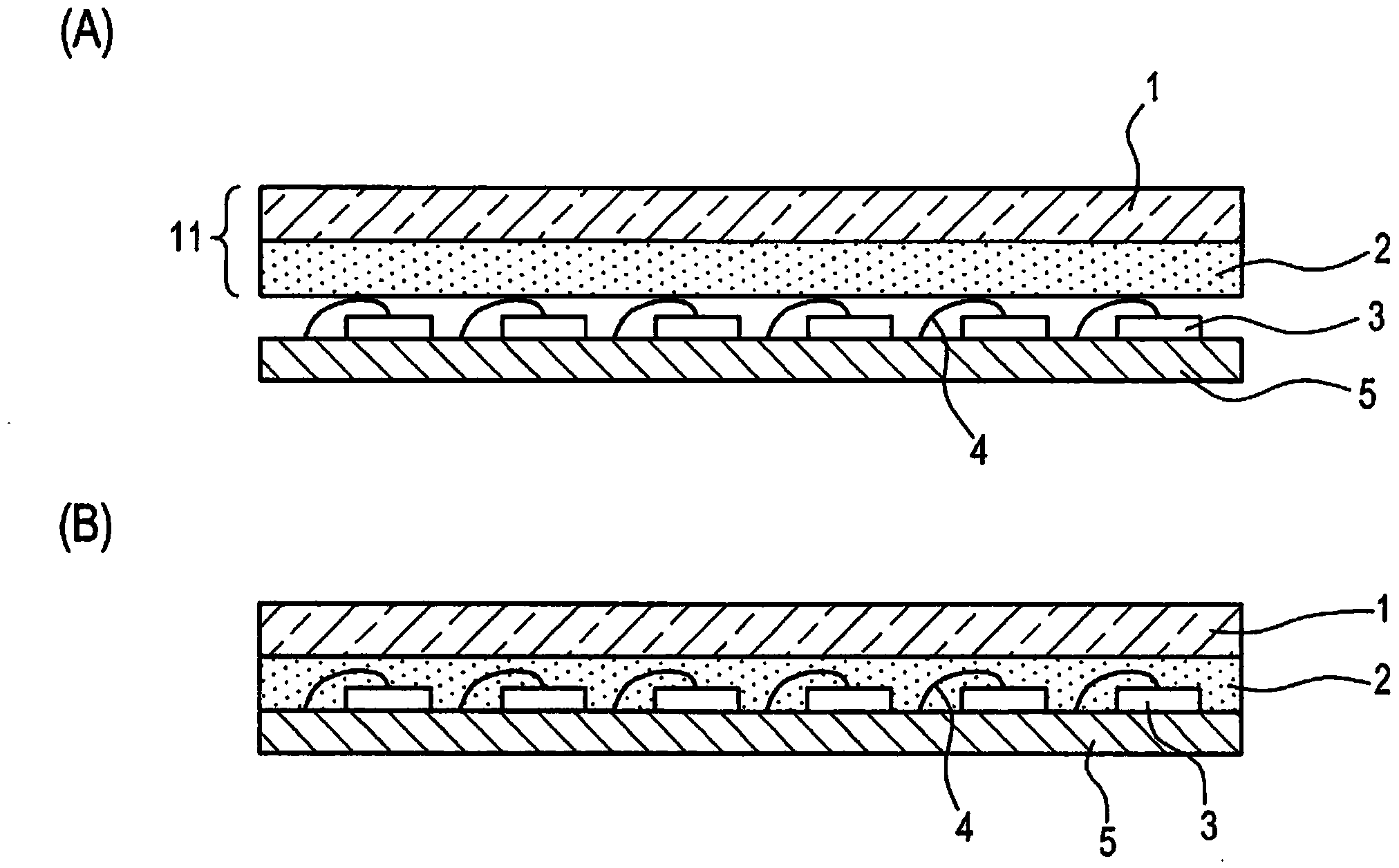

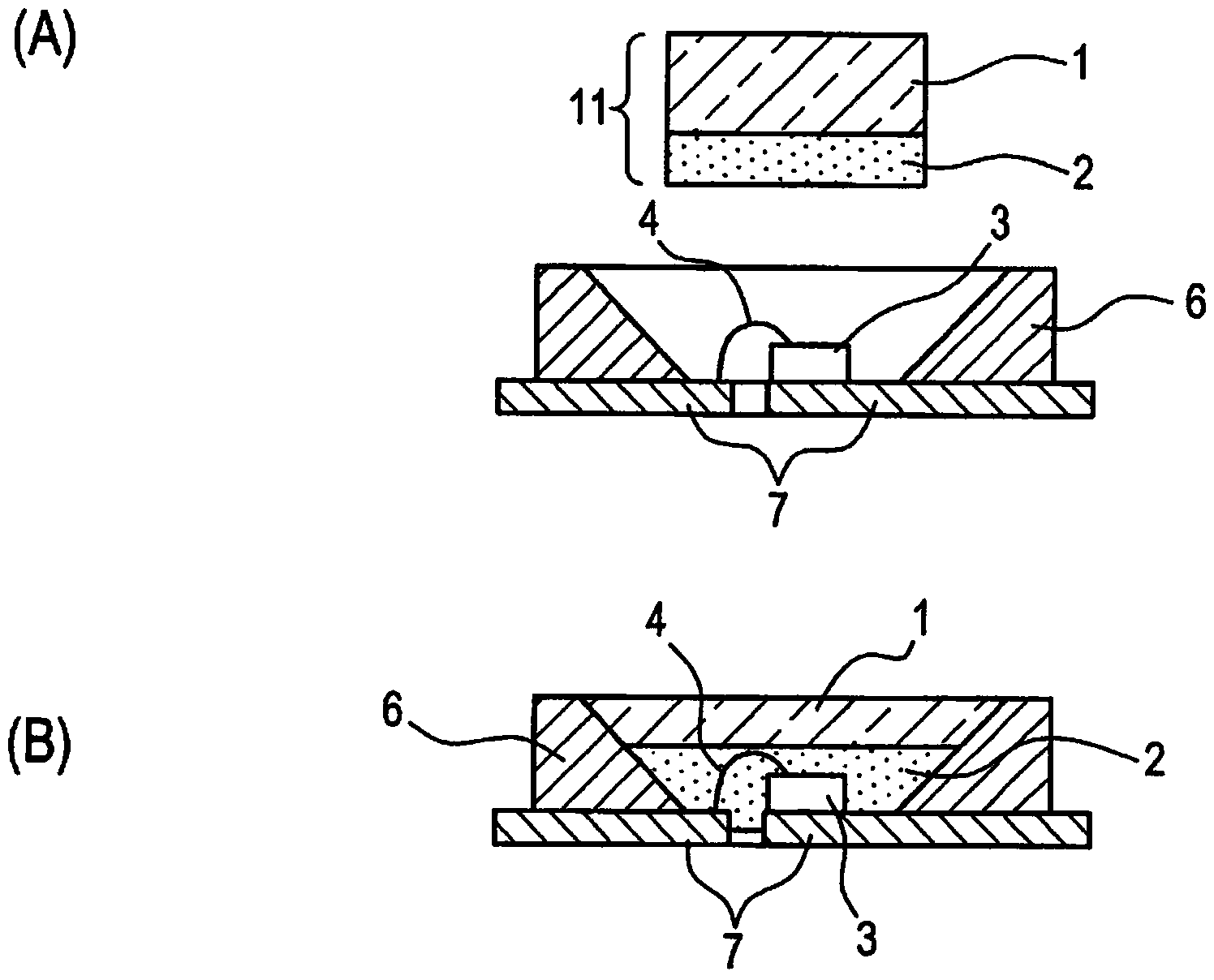

[0192] In order to produce the two-layer laminated silicone resin sheet of the present invention, the silicone resin composition (2) containing the phosphor is processed in a sheet form on a release film by using a film coater and a hot press. Then, a white heat-curable silicone resin composition (1) containing a white pigment is...

Embodiment

[0209] Although the present invention is specifically described below by describing synthesis examples, preparation examples, examples and comparative examples, the present invention is not limited to the following examples. In addition, in the following examples, the viscosity is a value at 25°C. In addition, weight average molecular weight is the polystyrene conversion value measured by gel permeation chromatography (GPC).

Synthetic example 1

[0211] -Organopolysiloxane resin containing vinyl group (A1)-

[0212] will consist of PhSiCl 3 Organosilanes shown: 27 moles, ClMe 2 SiO(Me 2 SiO) 33 SiMe 2 Cl: 1 mole, MeViSiCl 2 : After 3 moles were dissolved in toluene solvent, it was added dropwise in water, co-hydrolyzed, further washed with water, neutralized by washing with alkali, dehydrated, and then the solvent was removed to synthesize a vinyl group-containing resin (A1). The resin, its siloxane units and the [-SiMe 2 O-(Me 2 SiO) 33 -SiMe 2 o 2 / 2 ] The composition ratio of the structure represented by the chemical structural formula is expressed as:

[0213] [PhSiO 3 / 2 ] 0.27 [-SiMe 2 O-(Me 2 SiO) 33 -SiMe 2 o 2 / 2 ] 0.01 [MeViSiO 2 / 2 ] 0.03 . The resin had a weight average molecular weight of 62,000 and a melting point of 60°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com