Laser anti-collision early warning system used for bulk cargo stockyard

An early warning system and anti-collision technology, which is applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as being easily affected by signal chains, being unable to obtain real-time distance and orientation information of obstacles, and affecting operations. Achieve the effect of avoiding ambiguity and false alarms, achieving accuracy and timeliness, and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

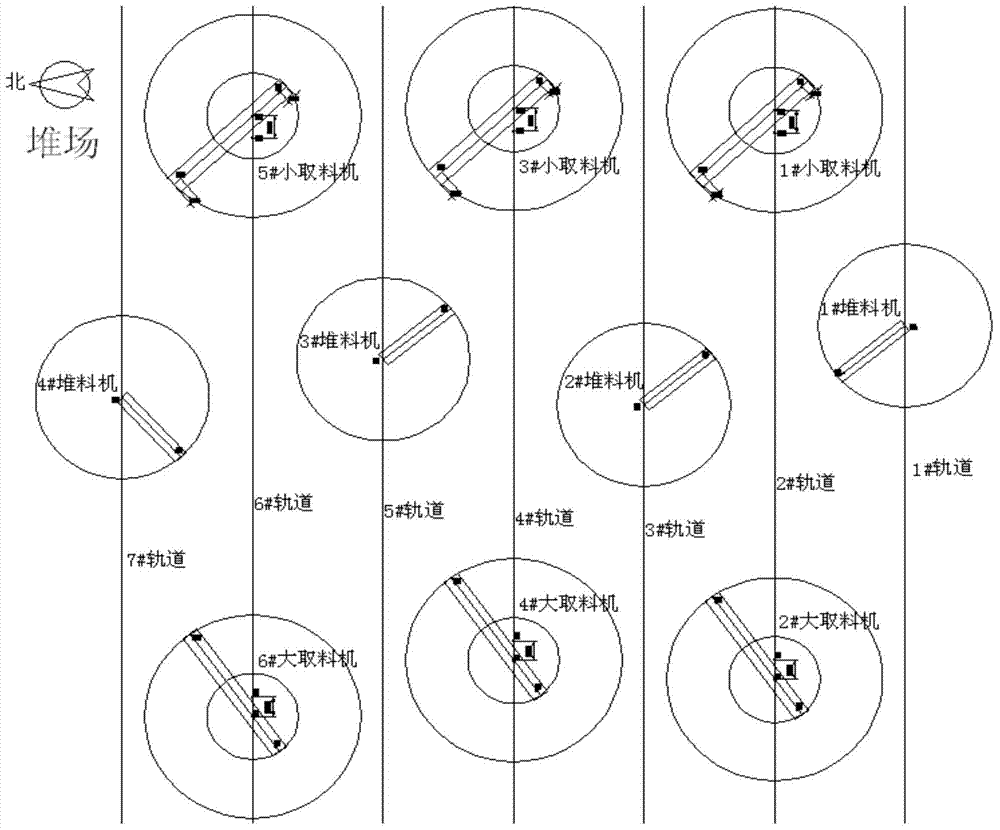

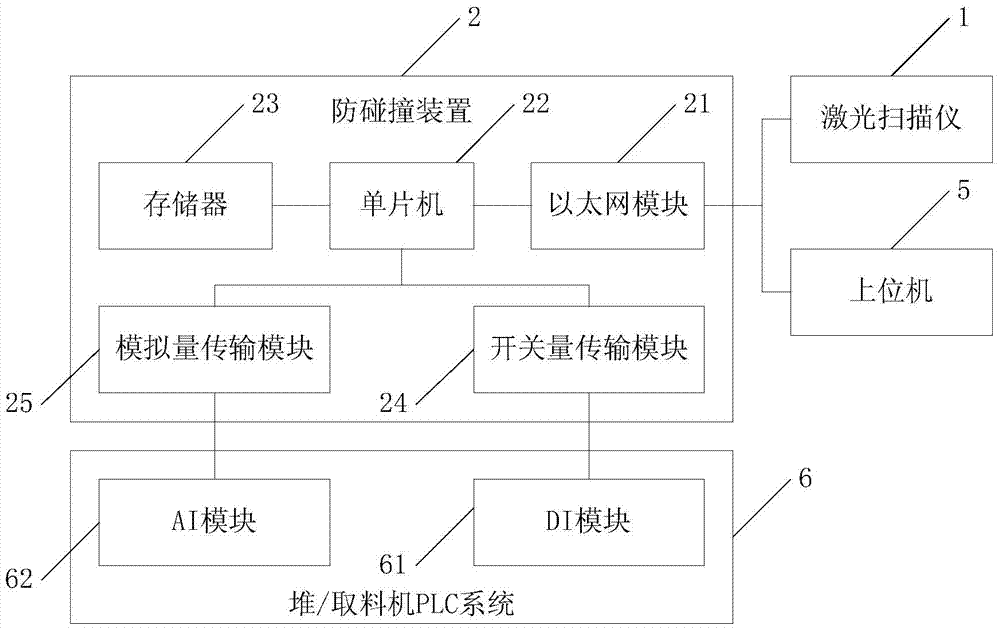

[0039] see Figure 2-Figure 4 , The present invention, that is, a laser anti-collision early warning system for bulk cargo yards, includes: two laser scanners 1 and an anti-collision device 2 connected to the laser scanner 1 network.

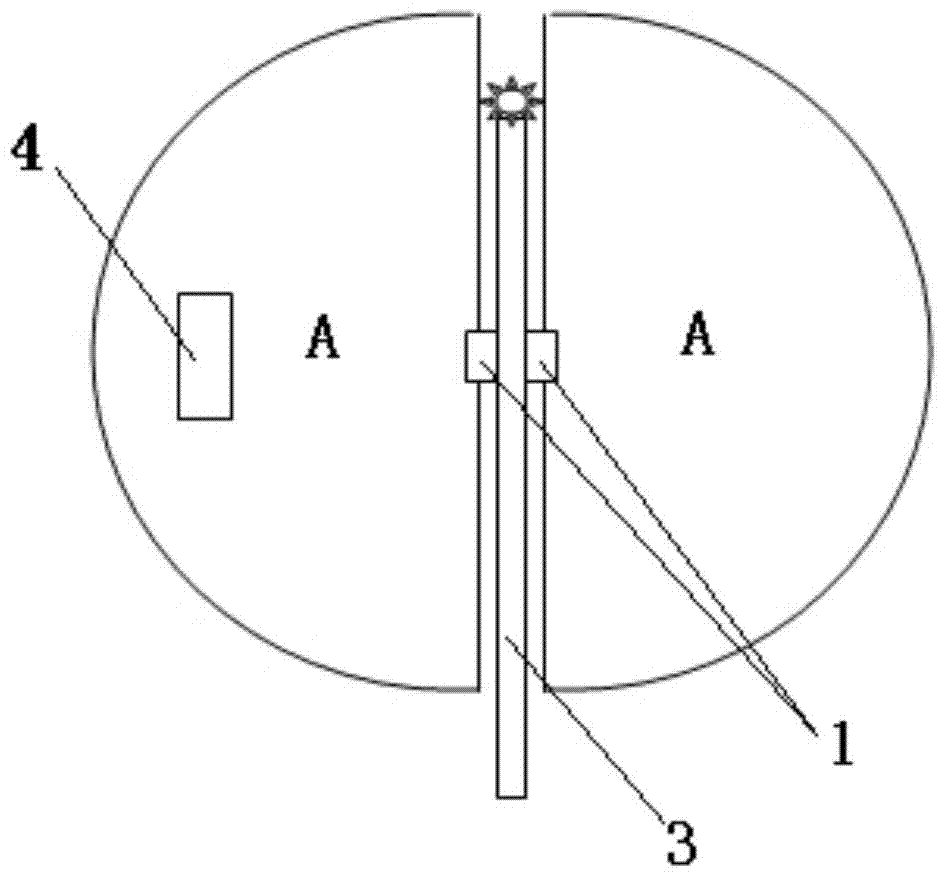

[0040] The laser scanner 1 is installed on the cantilever 3 of the stacker / reclaimer distributed in the bulk cargo yard, and a laser scanner 1 is respectively installed at a fixed position on both sides of each cantilever 3, and the laser scanner 1 is used for Obtain the information of obstacle 4 within the scanning range A (including the distance and orientation of the obstacle), and transmit the scanning point data containing the obstacle information to the anti-collision device 2 in real time in the form of communication messages through Ethernet; In the embodiment, the laser scanner 1 adopts the German SICK LMS5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com