Method for preparing high-purity thymalfasin

A new and high-purity technology of thymus method, which is applied in the preparation method of peptides, thymosin, chemical instruments and methods, etc., can solve the problems such as the difficulty of synthesizing peptides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

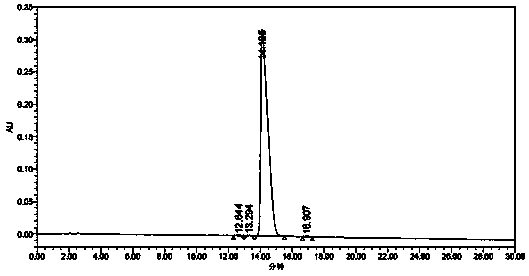

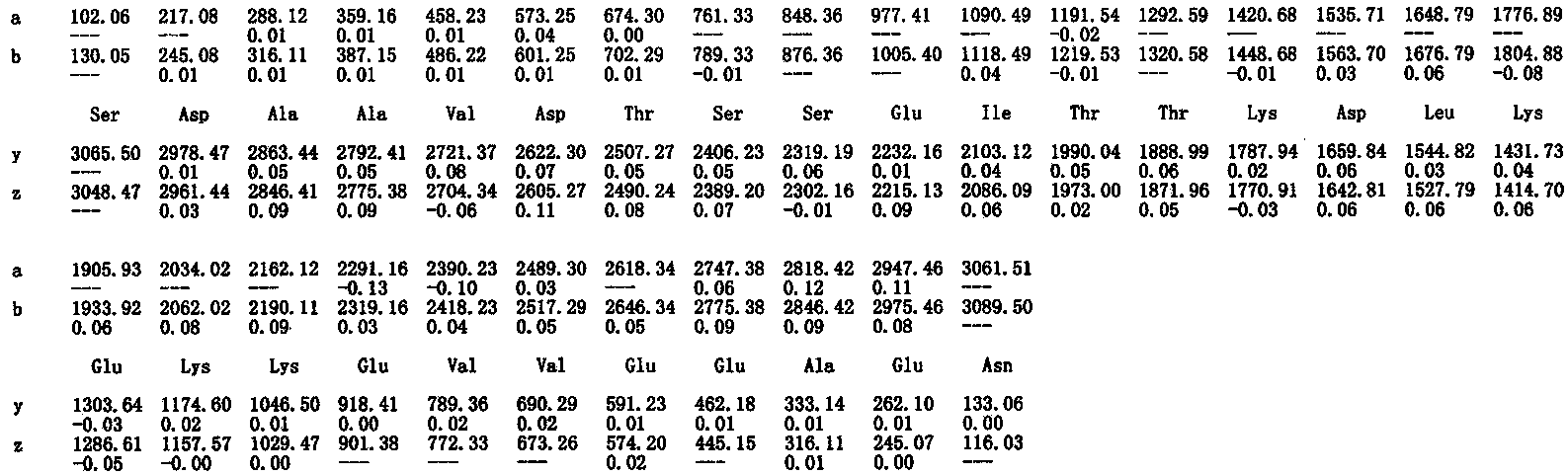

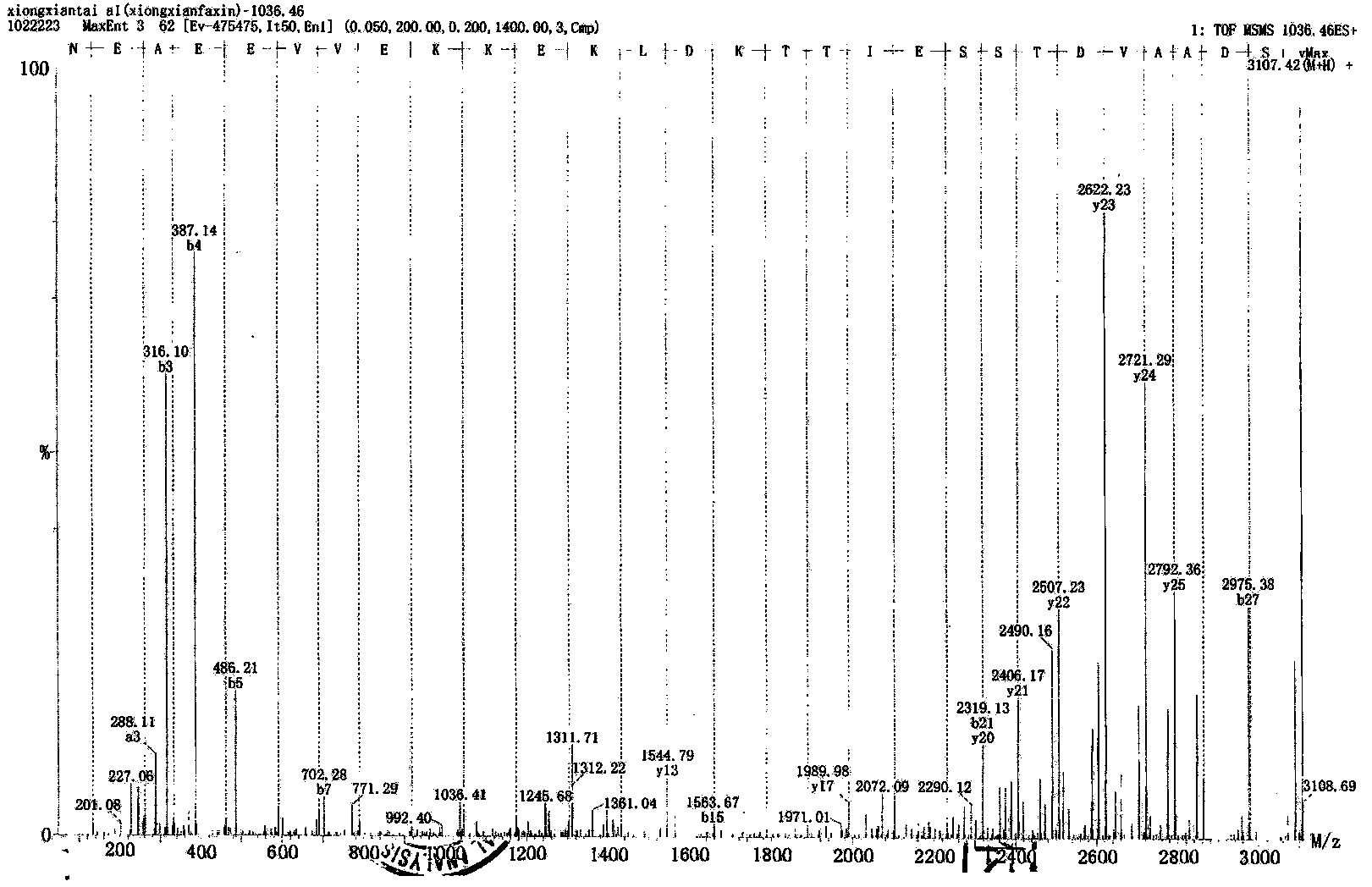

Image

Examples

Embodiment

[0076] The present invention prepares the new method of high-purity thymus method, and the detailed steps of this preparation method are as follows:

[0077] (1) Preparation of polypeptide fragment-Asn-Glu-Ala-Glu-Glu-Val-Val-Glu-Lys-Lys-Glu resin:

[0078] a. First add Fmoc-Asn(Trt)-wang resin resin into the container, then add dimethylformamide to swell, the swelling time is 30min; the ratio of the amount of the resin to dimethylformamide For 1g resin: 10mL dimethylformamide;

[0079]b, the resin after step a swelling is added in the mixed solution of piperidine and dimethylformamide to carry out deprotection, the mass ratio between piperidine and dimethylformamide in the mixed solution is 1:1, every gram of Fmoc -Asn(Trt)-wang resin was added to 10mL of the mixture, and after deprotection, it was washed 5 times with dimethylformamide;

[0080] c. Add the deprotected and washed resin in step b into the reactor, then add Fmoc-Glu(OtBu)-OH amino acid, condensation agent HATU...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com