Chlorinated polyethylene rubber material

A technology of chlorinated polyethylene and rubber materials, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of aggravated wear, aggravated wear, abnormal combustion, etc., achieve oil resistance, small compression permanent deformation, and anti-aging performance , high tear strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

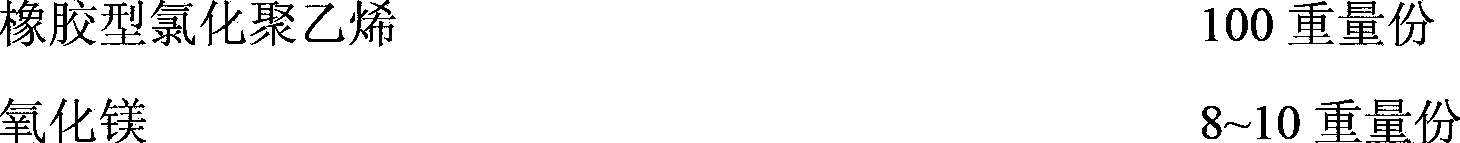

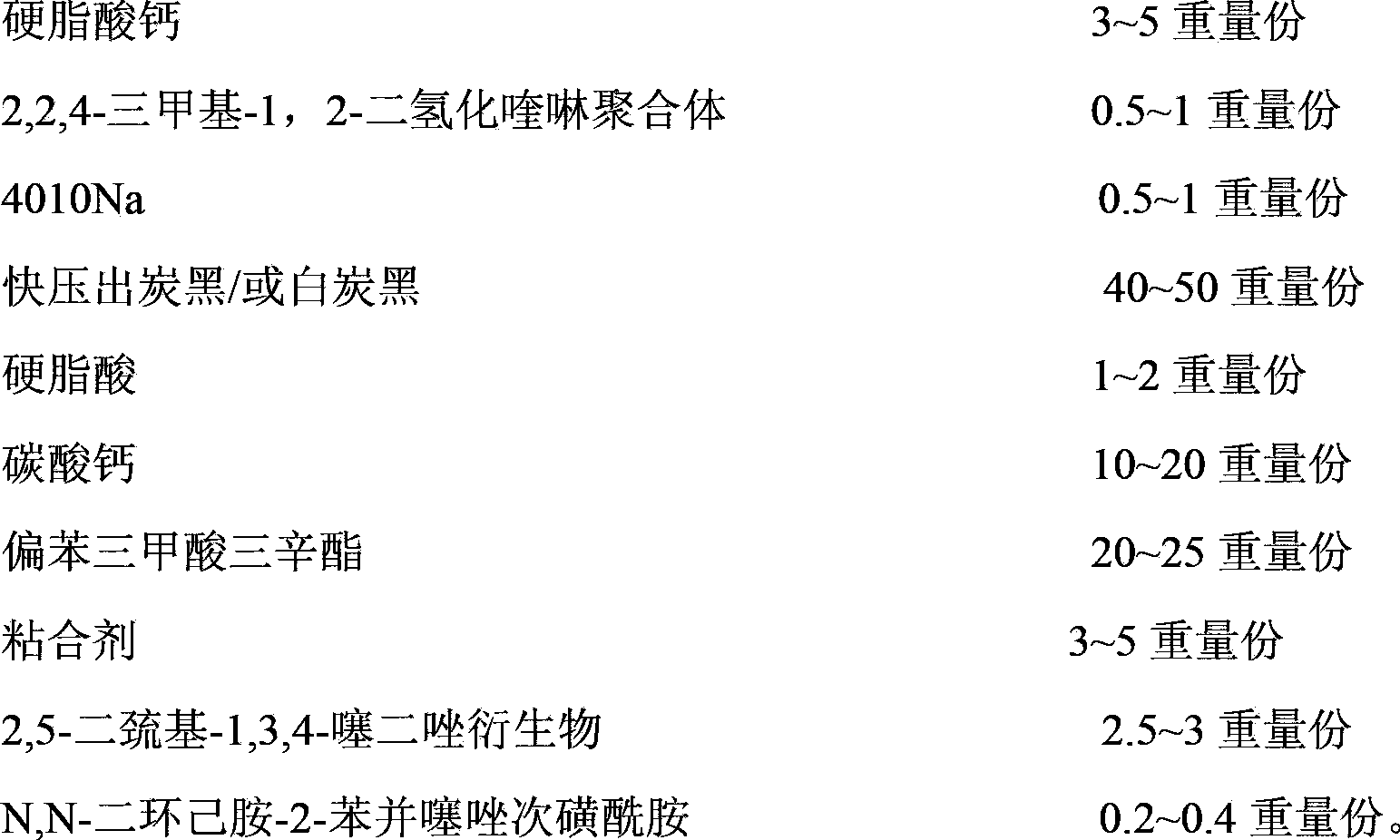

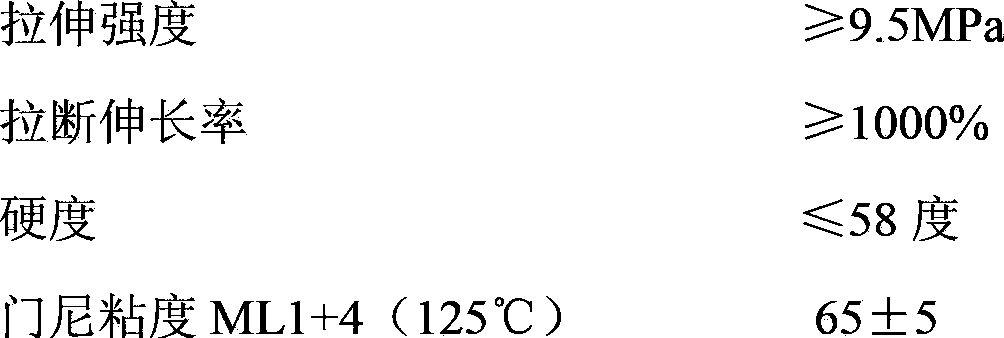

[0036] Chlorinated polyethylene rubber material formula:

[0037]

[0038]

[0039] The method for preparing the chlorinated polyethylene rubber that automobile cooling water hose is used is:

[0040] First, weigh chlorinated polyethylene rubber and various additives according to the formula, and first mix the additives except N,N-dicyclohexylamine-2-benzothiazole sulfenamide and ECHO-A with the weighed Put the chlorinated polyethylene rubber into the internal mixer at 60°C, and control the rubber mixing temperature not to exceed 85°C by passing cooling water. After 4 minutes of rubber mixing, add N,N-dicyclohexylamine-2-benzothiazole sulfenyl The amide and ECHO-A are mixed for about 2 minutes to discharge, and 4~5 triangular bags are made on the open mill, and then the tablets are released and parked for later use. First preheat the rubber material to 55°C, extrude the hose under the condition that the temperature of the extruder body is 60°C, and the temperature of th...

Embodiment 2

[0048]

[0049]

[0050] The method for preparing the chlorinated polyethylene rubber that automobile cooling water hose is used is:

[0051] First, weigh the chlorinated polyethylene rubber and various additives according to the formula, and mix the additives except ECHO-A and N,N-dicyclohexylamine-2-benzothiazole sulfenamide with the weighed Chlorinated polyethylene rubber is put into a 70°C internal mixer, and the temperature of the rubber mixing is controlled not to exceed 85°C by passing cooling water. After mixing the rubber for 5 minutes, add N,N-dicyclohexylamine-2-benzothiazole sulfenyl The amide and ECHO-A are mixed for about 2 minutes to discharge, and 4~5 triangular bags are made on the open mill, and then the tablets are released and parked for later use. Put the rubber material into the extruder to extrude the rubber hose. The temperature of the extruder body is 70 ℃, and the temperature of the head is 75 ℃ to extrude the rubber hose. The rubber hose is se...

Embodiment 3

[0053]

[0054] The method for preparing the chlorinated polyethylene rubber that automobile cooling water hose is used is:

[0055] First, weigh the chlorinated polyethylene rubber and various additives according to the formula, and mix the additives except ECHO-A and N,N-dicyclohexylamine-2-benzothiazole sulfenamide with the weighed Put chlorinated polyethylene rubber into the internal mixer at 55°C, and control the temperature of rubber mixing to not exceed 85°C by passing cooling water. After 4 minutes of rubber mixing, add N,N-dicyclohexylamine-2-benzothiazole sulfenyl The amide and ECHO-A are mixed for about 2 minutes to discharge, and 4~5 triangular bags are made on the open mill, and then the tablets are released and parked for later use. First preheat the rubber material to 55°C, extrude the hose under the condition that the temperature of the extruder body is 50°C, and the temperature of the head is 90°C. The rubber hose is sent into a steam vulcanization tank fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com