Method for preparing films with anisotropic light enhanced transmission property

An anisotropic, thin-film technology, applied in the field of preparation of asymmetric semi-cone-shell nanohole array membranes, can solve few problems such as asymmetric three-dimensional nanohole array research work, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

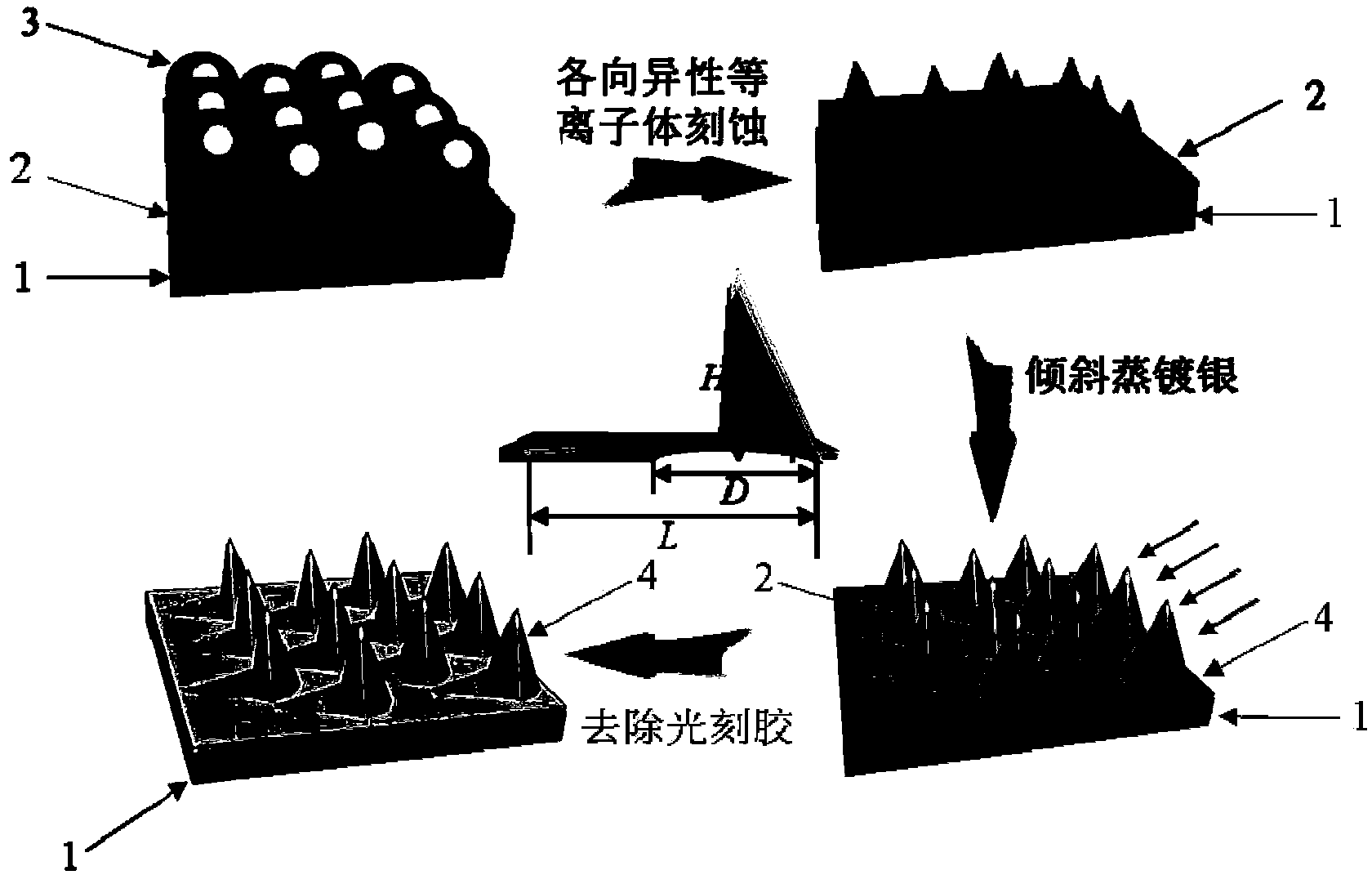

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: the preparation of hydrophilic glass sheet

[0024] The glass sheet used was cut to 2.5cm long and 3.5cm wide with a glass knife, put into a mixed solution of concentrated sulfuric acid and hydrogen peroxide (volume ratio 7:3) and heated to 80°C in a water bath, and kept for 5 hours to obtain the Water glass flakes; pour the mixed solution into a waste liquid bottle, wash the obtained glass flakes with deionized water for 3 to 5 times, and dry them with nitrogen.

Embodiment 2

[0025] Embodiment 2: the preparation of photoresist film

[0026] Collagen photoresist solution (BP212-37, positive photoresist, purchased from Beijing Kehua Microelectronics Materials Co., Ltd.) was spin-coated at a speed of 3000rpm for 30 seconds with a desktop coater, and then spin-coated onto the hydrophilic treated glass Then place it in an oven at 100°C for aging treatment for 0.5 hours, take it out and leave it at room temperature, so as to obtain a photoresist film with a thickness of 2 μm on the substrate.

Embodiment 3

[0027] Embodiment 3: Preparation of hydrophobic polystyrene microspheres

[0028] At room temperature, add 3 mL of deionized water to 1 mL of 5 wt % polystyrene microsphere dispersion with a diameter of 700 nm, centrifuge at 6000 rpm for 5 minutes, absorb the supernatant, and add 3 mL of deionized water and centrifuged again, after which the process was repeated 7 times. After absorbing the supernatant for the last time, add 1mL of ethanol and 1mL of deionized water to the solid matter, centrifuge at 6000rpm for 5 minutes, absorb the supernatant, and then add the same ethanol and deionized water to the remaining solid matter The mixed solution of water was centrifuged in the same way, and the centrifugation process was repeated 16 times. After the supernatant was drawn for the last time, 1 mL of ethanol and 1 mL of deionized water were finally added to the solid to obtain a hydrophobic 10wt% polystyrene microsphere. Dispersion of spheres in ethanol and deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com