RFID tag and its manufacturing method

A technology of RFID tags and manufacturing methods, applied in the field of radio frequency identification, can solve the problems of inability to be used as ear tags for livestock, complicated manufacturing processes, high cost, and achieve the effects of easy mass production, improved gain performance, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] RFID tags, including tag parts and casings;

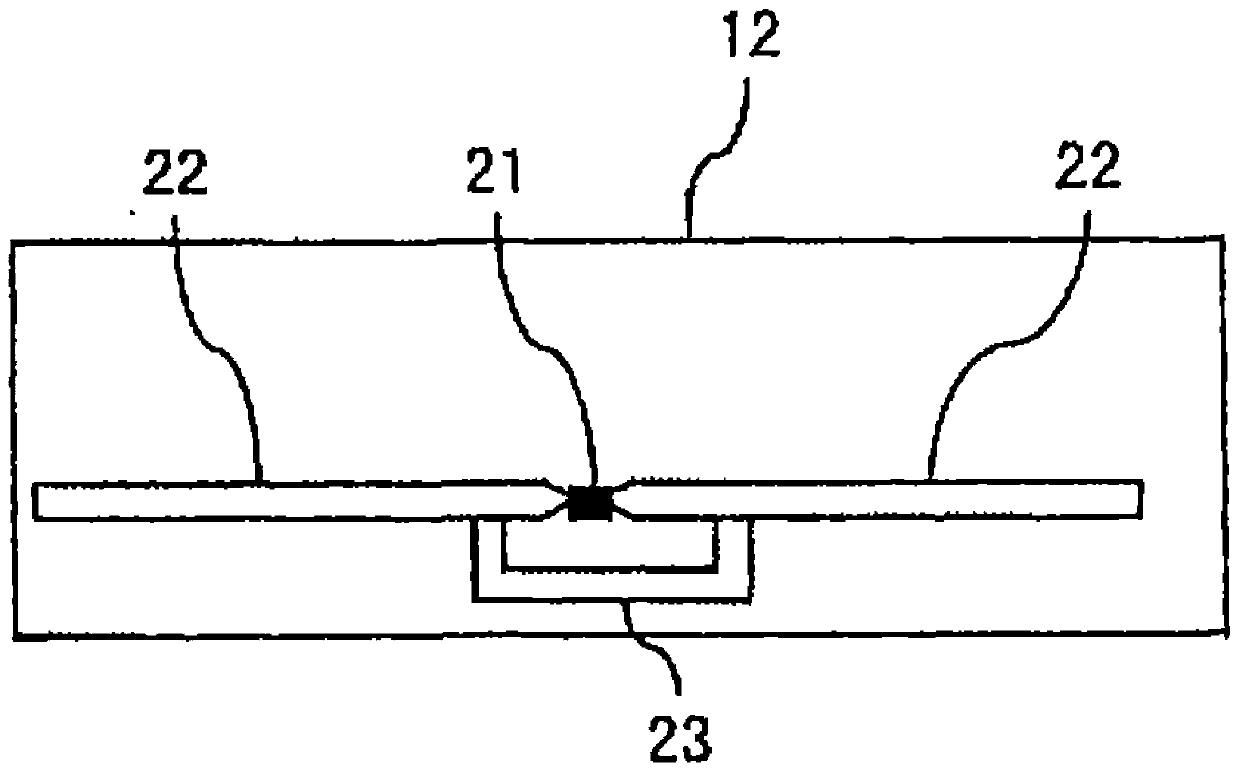

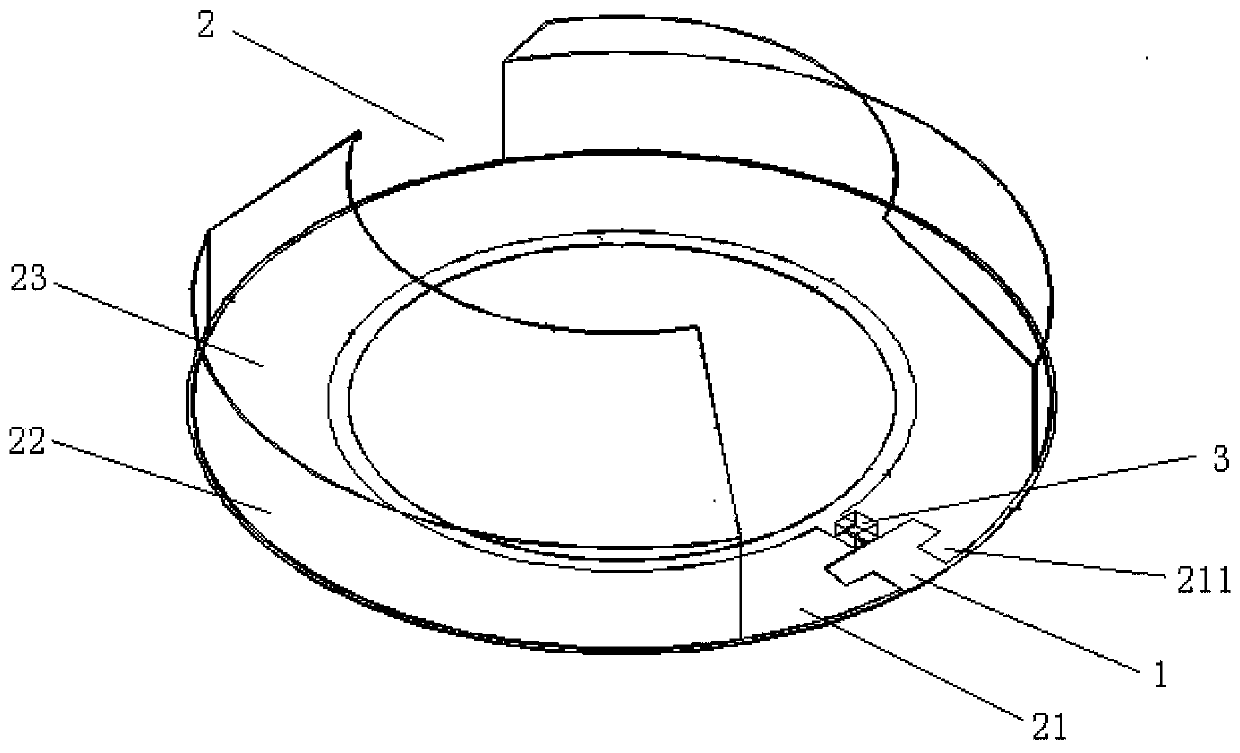

[0053] The label section, such as figure 2 As shown, it includes an insulating film 1, a tag antenna 2, and a tag chip 3;

[0054] The tag antenna 2 is attached to the upper surface of the insulating film 1;

[0055] The tag antenna 2 includes an annular metal patch 21, a first cylindrical metal patch 22, a second cylindrical metal patch 22, a first frustum-shaped metal patch 23, a second frustum-shaped metal patch Metal patch 23;

[0056]The annular metal patch 21 has a gap;

[0057] Two short leads 211 are respectively formed on the left and right sides of the notch of the annular metal patch 21;

[0058] The bottom edge of the first cylindrical metal patch 22 is connected to the outer edge of the annular metal patch 21 on the left side of the notch;

[0059] The bottom edge of the second cylindrical metal patch 22 is connected with the outer edge of the annular metal patch 21 on the right side of the gap;

[0060] ...

Embodiment 2

[0066] Based on embodiment one,

[0067] The RFID tag is an ultra-high frequency (UHF) RFID tag; the tag antenna 2 is a dipole antenna;

[0068] The label chip is welded together with two short leads on the inner edge of the annular metal patch 21 in an upside-down manner;

[0069] The insulating film 1 is a PET (polyethylene terephthalate) film or a PI (polyimide) film;

[0070] The metal patch (annular metal patch 21, the first cylindrical metal patch 22, the second cylindrical metal patch 22, the first frustum-shaped metal patch 23, the second frustum-shaped metal patch The patch 23) is an aluminum patch or a copper patch.

[0071] Preferably, the insulating film 1 has a thickness of 10-200 μm, and the metal patch has a thickness of 0.01-0.1 mm.

Embodiment 3

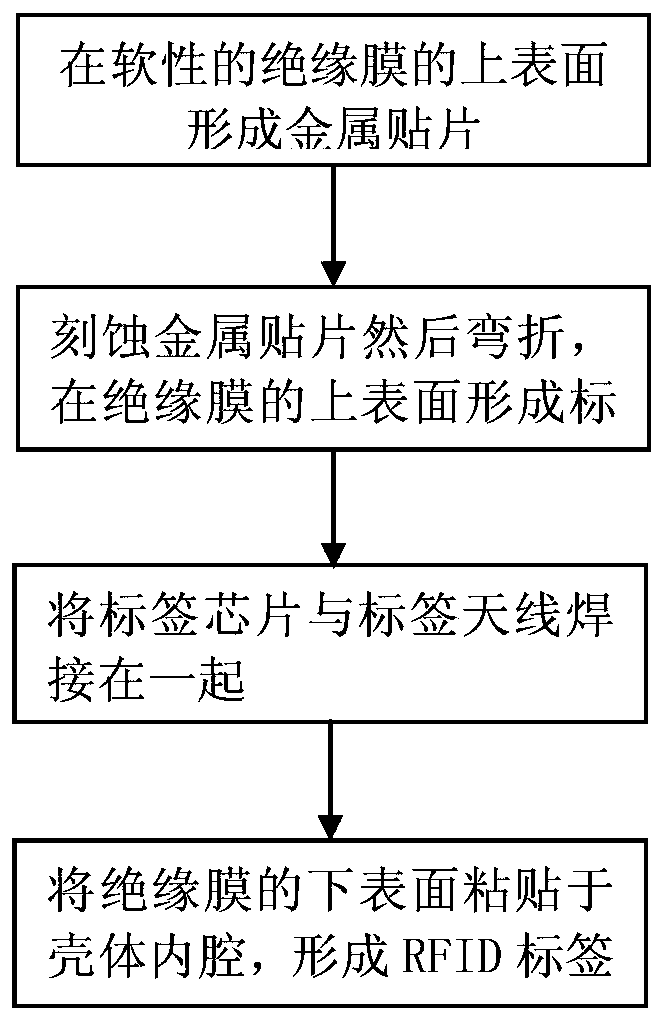

[0073] Manufacturing methods of RFID tags, such as image 3 shown, including the following steps:

[0074] one. Form a metal patch on the upper surface of the flexible insulating film;

[0075] Preferably, the insulating film is PET (polyethylene terephthalate) or PI (polyimide) film, with a thickness of 10-200 μm;

[0076] Preferably, the metal patch is an aluminum patch or a copper patch, with a thickness of 0.01-0.1mm;

[0077] two. Etching the metal patch and then bending it to form a tag antenna on the upper surface of the insulating film 1;

[0078] three. Welding the tag chip and the tag antenna together to form a processed soft tag part;

[0079] Four. Paste the lower surface of the insulating film (attached with tag antenna and tag chip) to the inner cavity of the housing to form an RFID tag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com