Power energy storage polymer lithium ion battery and preparation method thereof

A lithium-ion battery and power energy storage technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., to achieve the effects of reducing production costs, improving electrical conductivity, and increasing rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

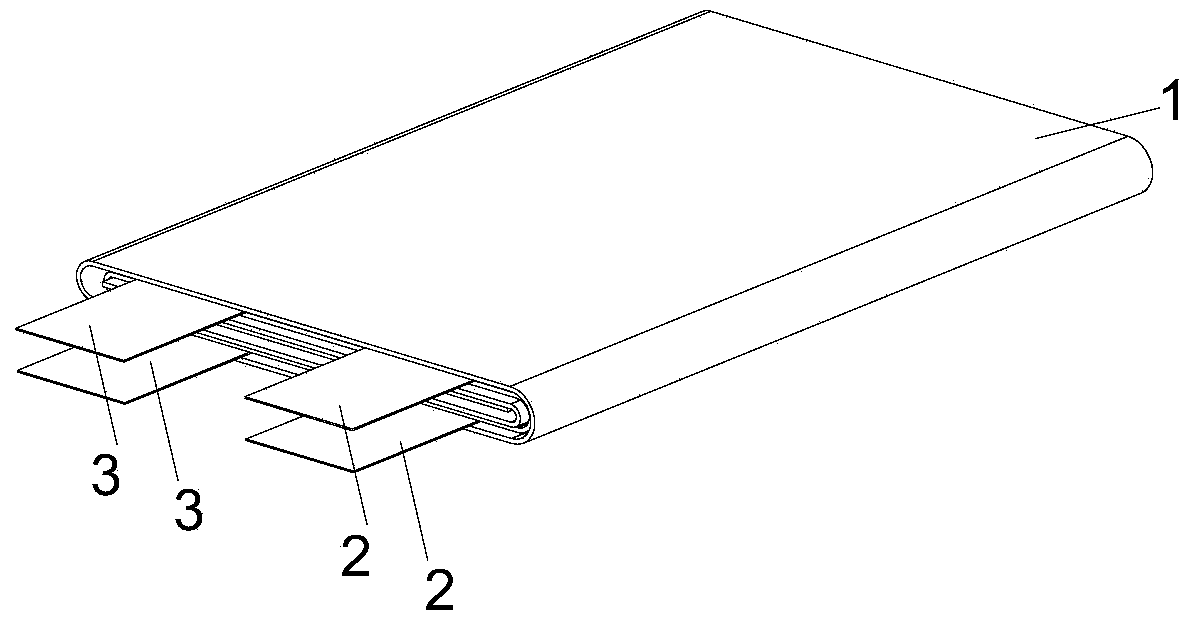

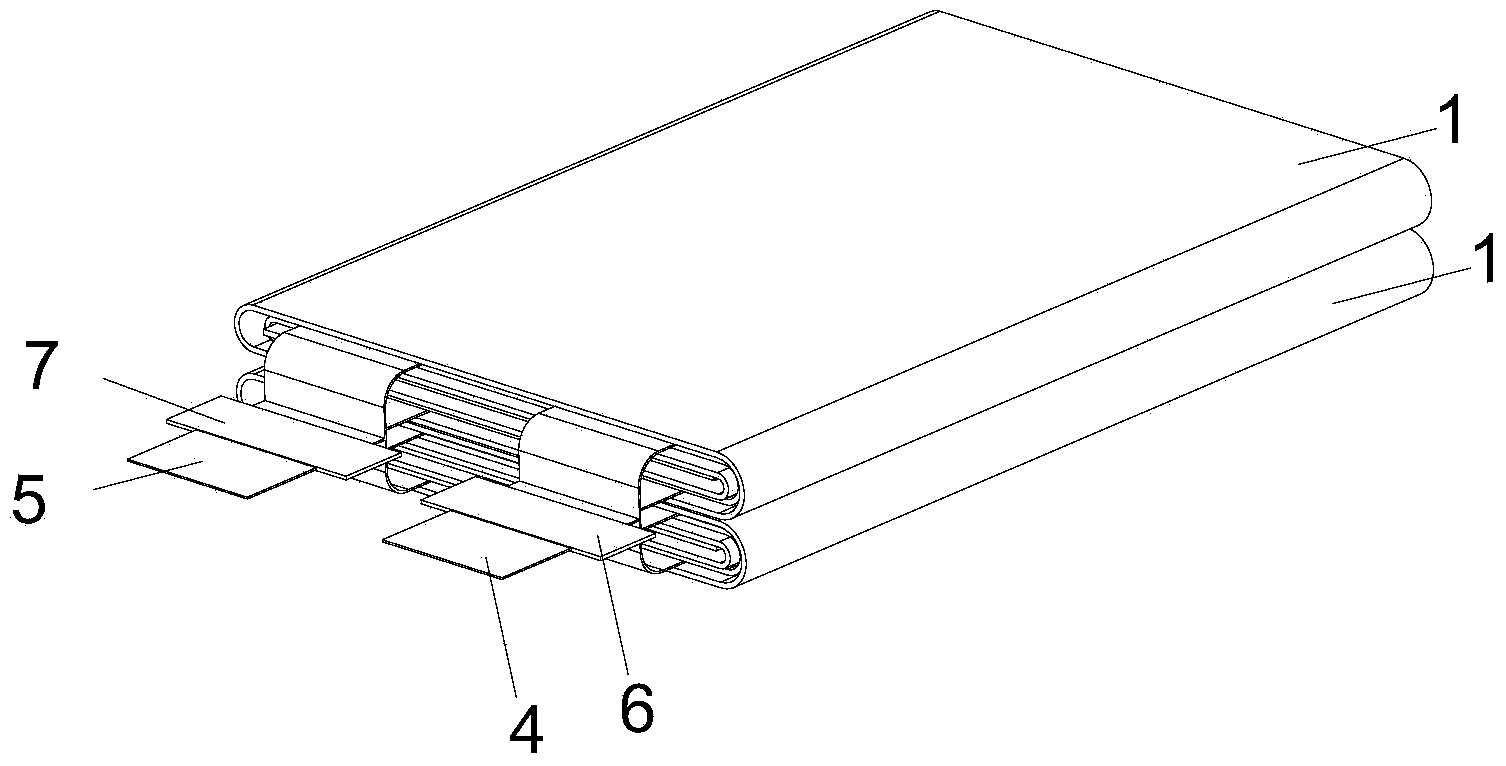

[0043] Depend on figure 1 with figure 2 As shown in: the battery produced by the method of the present invention includes a cell main body 1, a positive pole tab 2, a negative pole tab 3, a positive pole tab 4 with a sealant, a negative pole tab 5 with a sealant, and a positive pole tab Sealant 6 and negative electrode lug sealant 7. The positive electrode sheet and the negative electrode sheet are respectively made of a molecular-level ultrafine dispersed positive and negative electrode slurry; the battery is composed of two electric cores connected in parallel; each of the two electric cores contains a bipolar ear And the inside of the double-pole ear double-core is a parallel winding structure. The internal parallel winding structure of double-pole tabs and double-cores can reduce the internal resistance of the battery, improve the battery rate performance, and have high production efficiency and reduce the production cost of the battery.

[0044] In this embodiment, th...

Embodiment 2

[0067] The preparation of the power energy storage polymer lithium-ion battery in this embodiment specifically includes the following steps:

[0068] A. Preparation of positive electrode slurry and positive electrode sheet:

[0069] ① Raw materials are prepared in the following proportions by weight:

[0070] Polyvinylidene fluoride (PVDF): 3.0kg, nanocomposite conductive agent: 2.0kg, positive electrode material nickel cobalt lithium manganate Li(Ni x co y mn 1-x-y )O 2 : 5.0kg, positive electrode material lithium iron phosphate: 85.0kg.

[0071] Add 3.0kg of lithium battery binder polyvinylidene fluoride to 30Wt% solvent N-methylpyrrolidone (NMP) in the mixer, heat up and keep the solvent temperature at 60±5°C, and rotate at 2000 rpm in the mixer , the revolution speed is 45 revolutions / min, and the vacuum high-temperature stirring is carried out to obtain the first-stage binder slurry of 2000-3500Mpa s;

[0072] ② Add 2.0kg of nanocomposite conductive agent and 5.0kg ...

Embodiment 3

[0086] The preparation of the power energy storage polymer lithium-ion battery in this embodiment specifically includes the following steps:

[0087] 1. Preparation of positive electrode slurry and positive electrode sheet:

[0088] ① Raw materials are prepared in the following proportions by weight:

[0089] Polyvinylidene fluoride (PVDF): 5.0kg, nanocomposite conductive agent: 4.5kg, positive electrode material nickel cobalt lithium manganate Li(Ni x co y mn 1-x-y )O 2 : 3.0kg, positive electrode material lithium iron phosphate: 92.0kg.

[0090] Add 5.0kg of binder polyvinylidene fluoride to 15Wt% solvent N-methylpyrrolidone (NMP) in the mixer, heat up and keep the solvent temperature at 60±5°C, and rotate at 1500 revolutions / min in the mixer, revolution Vacuum high-temperature stirring at a speed of 30 rpm to obtain a first-stage binder slurry of 2000-3500Mpa s;

[0091] ②Add 4.5kg of nanocomposite conductive agent and 3.0kg of positive electrode material nickel-cobal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com