Package Structure of Distributed Feedback Fiber Laser

A fiber laser and packaging structure technology, which is applied in the structure/shape of the active medium, laser components, etc., to reduce the response sensitivity, facilitate integration, and achieve a compact overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

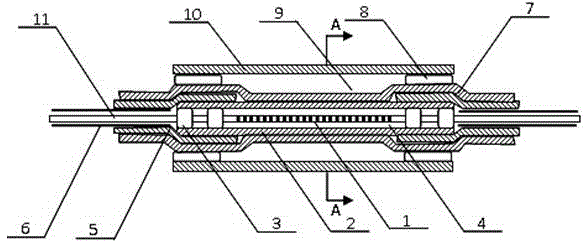

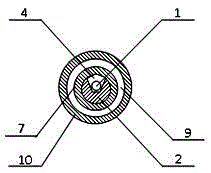

[0016] Embodiment 1: as figure 1 As shown, a packaging structure of an active phase-shifting fiber grating, which includes a quartz U-shaped groove 2 and silicone grease or silicone oil 4 filled in the quartz U-shaped groove 2, the active phase-shifting fiber grating 1 is immersed in the quartz U-shaped In the silicone grease or silicone oil 4 in the groove 2, the grating pigtails 11 at both ends of the active phase-shifting fiber grating 1 are bonded and fixed to the quartz U-shaped groove 2 through two parallel thermosetting adhesives 3 to make the active phase-shifting fiber grating 1 Keep a free state without bearing axial stress; the grating pigtails 11 located outside the quartz U-shaped groove 2 are respectively covered with plastic sleeves 6, and the two ends of the quartz U-shaped groove 2 together with the plastic sleeves 6 on both sides are inserted respectively Into the corresponding heat-melt tube 5, the two-section heat-melt tube 5 and the quartz U-shaped groove ...

Embodiment 3

[0021] Embodiment 3: The similarities between this embodiment and Embodiment 2 will not be repeated, and the difference is that the active phase-shifting fiber grating 1 is an 8cm long ytterbium-doped fiber grating, and the line width jumps in the range of 20-500kHz in a 60dB noise environment. Change, the relative intensity noise is up to -65dB. After the bare fiber is coated, the metal sleeve 10 made of a 10cm long quartz U-shaped groove 2 and a 10cm long copper tube is packaged according to the same steps. The semi-fluid in the tank 2 adopts thermal conductive silicone grease 4 . The linewidth of the packaged Ytterbium-doped distributed feedback fiber laser is basically stable at about 30kHz, and the relative intensity noise is kept below -80dB.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com