Prevention of starch degradation in pulp, paper or board making processes

A pulp and starch technology, applied in the field of biocidal system to prevent or reduce starch degradation in pulp, paper or board manufacturing methods, can solve paper quality problems, insufficient efficacy, increase starch dosage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

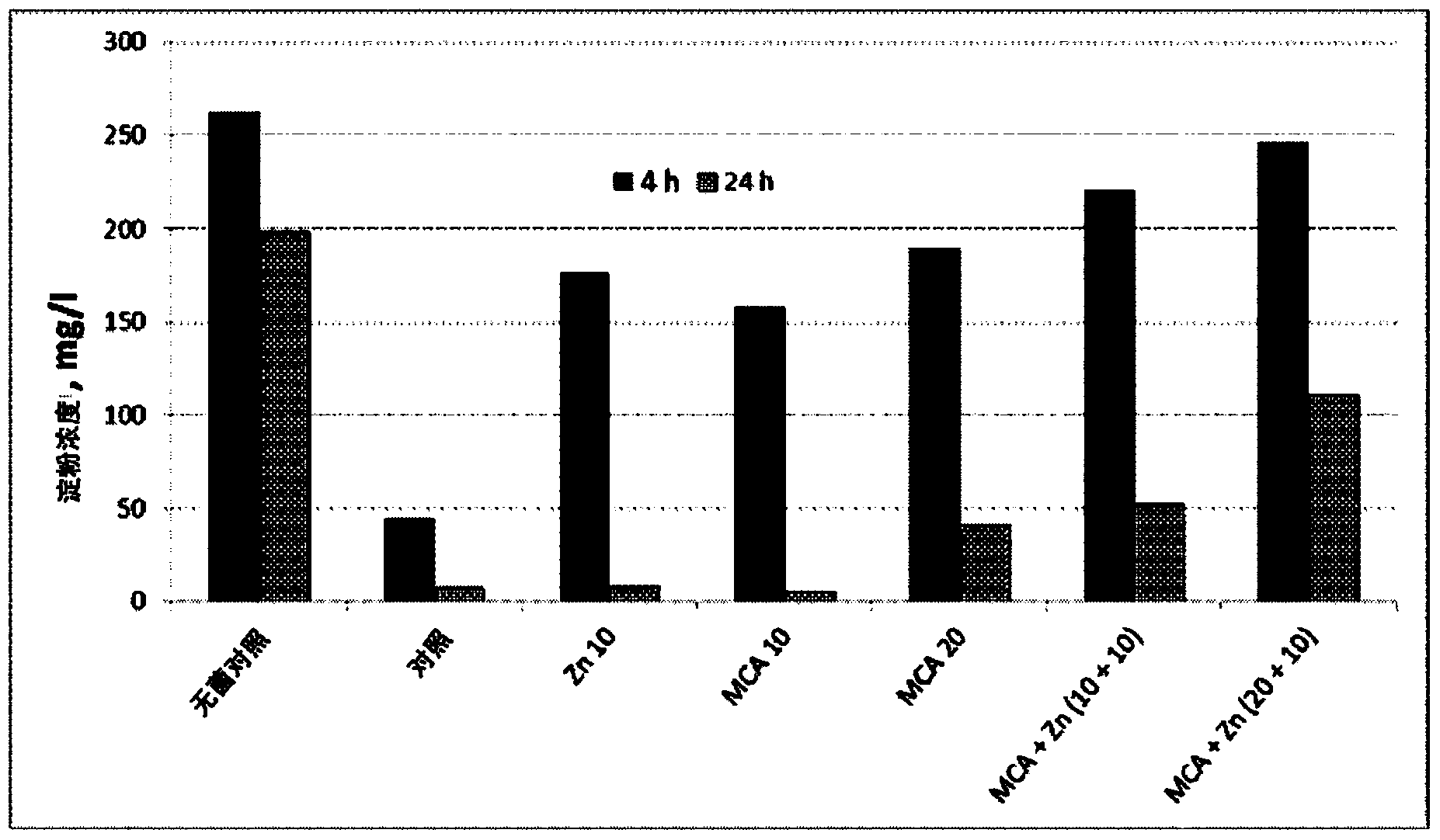

[0041] Use oxidizing biocides (monochloramine, MCA) and zinc to study the prevention of starch degradation. The head box slurry from the packaging board factory, which was collected and stored at +4°C, was amended with 0.8g / l cooked starch and incubated overnight at 45°C with shaking at 150rpm for induction The growth of starch degrading bacteria. Divide the slurry into 30ml portions, and combine the appropriate amount of zinc (Zn 2+ ) And MCA are added together with newly added starch (400mg / l). After 4h and 24h incubation (+45°C, 150rpm), the remaining starch was quantified using iodine staining (Lugol-solution) at 590nm. The external standard curve is used to convert the absorbance value into the amount of starch.

[0042] Table 1 and figure 1 It is shown that when there is no bacteria (sterile control), the measured starch concentration is about 250 mg / l after 4 h and 200 mg / l after 24 h. The remaining starch has probably been retained on the fiber. In the untreated contr...

Embodiment 2

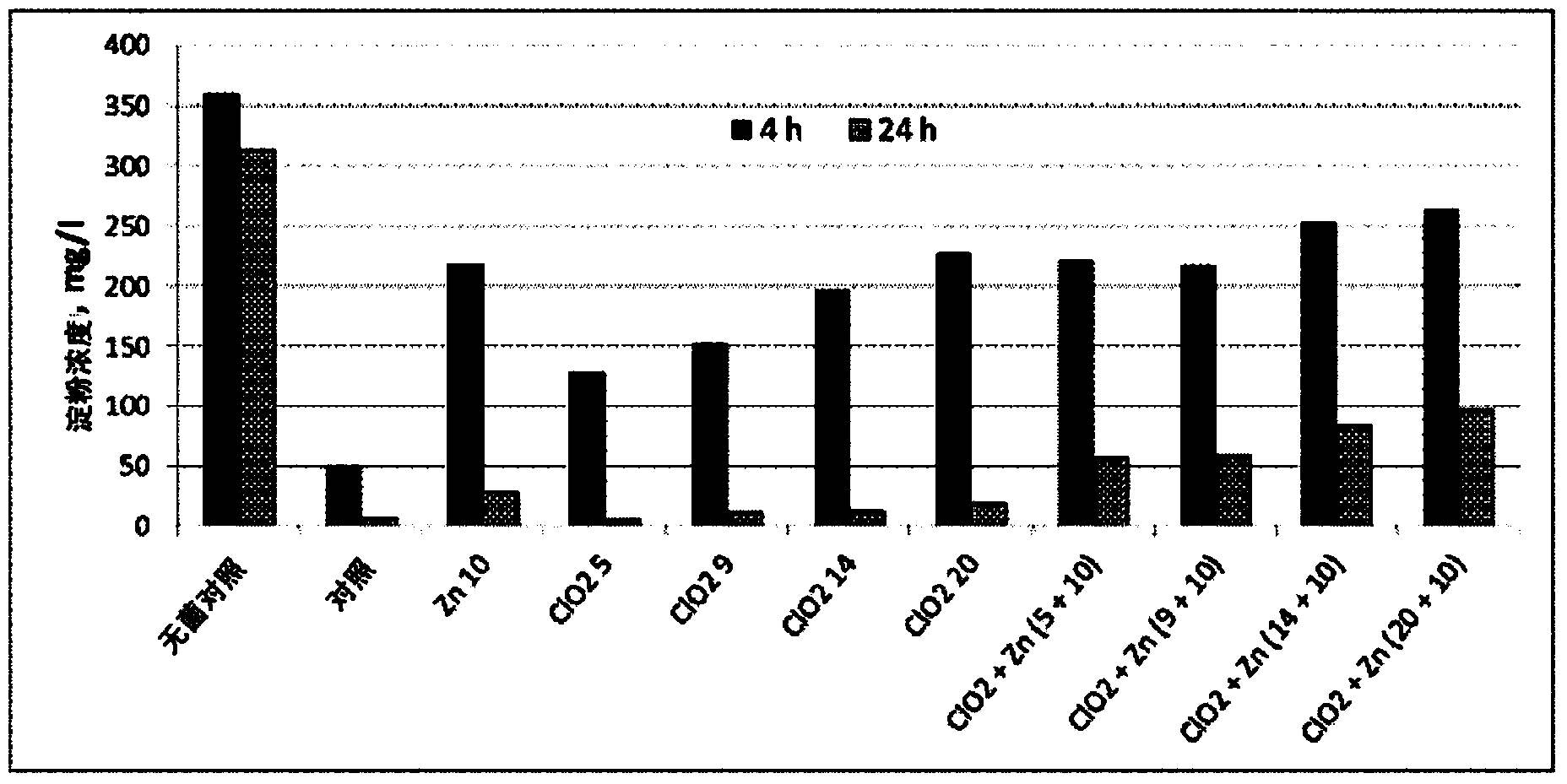

[0046] Use oxidizing biocides (chlorine dioxide, ClO 2 ) And zinc study the prevention of starch degradation. The head box slurry from the packaging board factory, which was collected and stored at +4°C, was modified with 0.8g / l cooked starch, and incubated overnight at 45°C under 150rpm shaking to induce starch degrading bacteria Growth. Divide the slurry into 30ml portions, and combine the appropriate amount of zinc (Zn 2+ ) And ClO 2 It is added together with newly added starch (400mg / l). After 4h and 24h incubation (+45°C, 150rpm), the remaining starch was quantified using iodine staining (Lugo's solution) at 590nm. The external standard curve is used to convert the absorbance value into the amount of starch.

[0047] Table 2 and figure 2 It is shown that when there is no bacteria (sterile control), the measured starch concentration is about 350 mg / l after 4 h and 300 mg / l after 24 h. The remaining starch has probably been retained on the fiber. In the untreated control,...

Embodiment 3

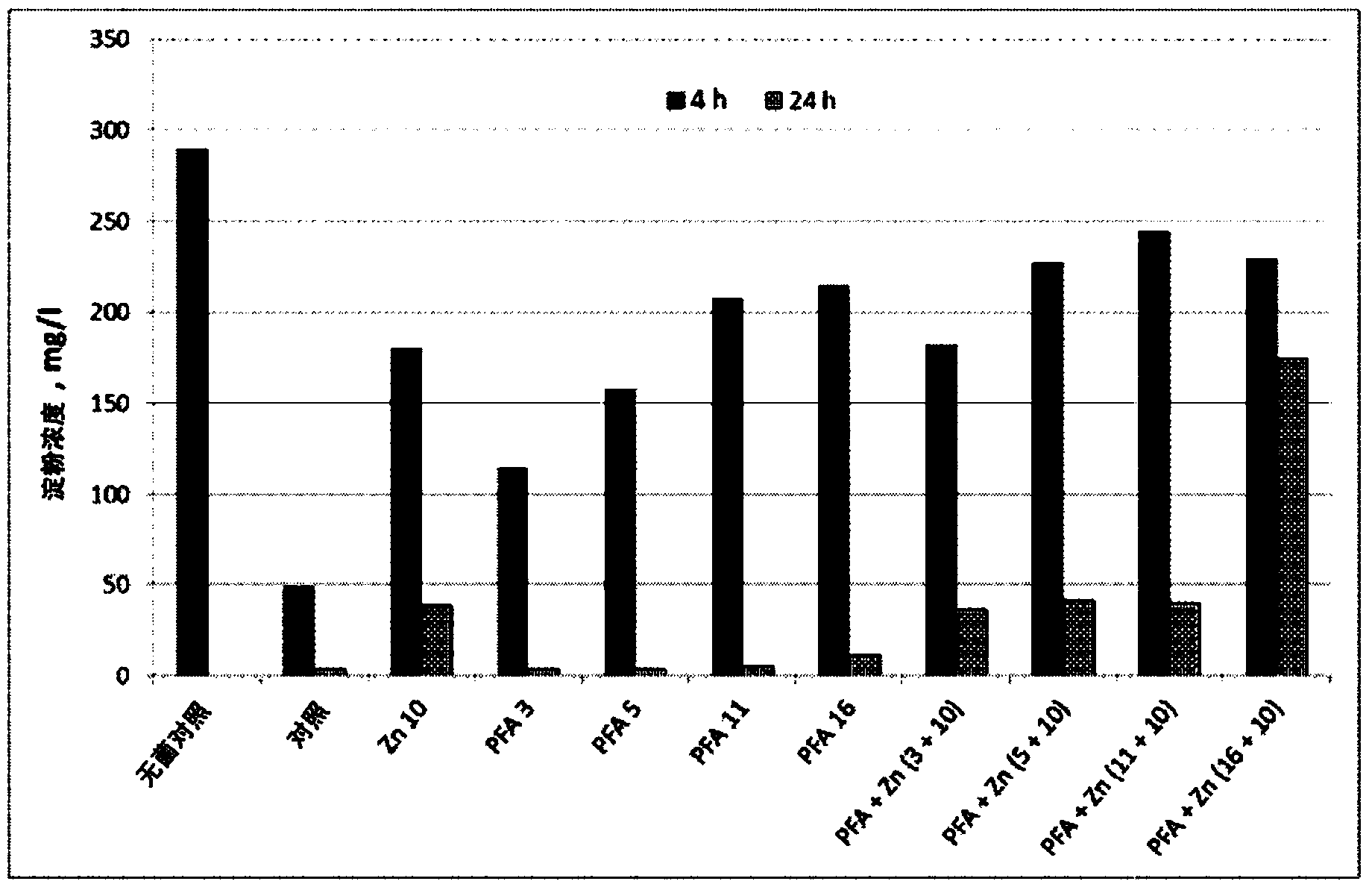

[0051] Using oxidizing biocides (performic acid, PFA) and zinc to study the prevention of starch degradation. The head box slurry from the packaging board factory, which was collected and stored at +4°C, was modified with 0.8g / l cooked starch, and incubated overnight at 45°C under 150rpm shaking to induce starch degrading bacteria Growth. The slurry was divided into 30 ml portions, and appropriate amounts of zinc (Zn2+ from zinc chloride) and PFA were added together with newly added starch (400 mg / l). After 4h and 24h incubation (+45°C, 150rpm), the remaining starch was quantified using iodine staining (Lugo's solution) at 590nm. The external standard curve is used to convert the absorbance value into the amount of starch.

[0052] Table 3 and image 3 It is shown that when there is no bacteria (sterile control), the measured starch concentration is about 300 mg / l after 4 h. The remaining starch has probably been retained on the fiber. In the untreated control, most of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com