A kind of soluble hyaluronic acid microneedle patch

A hyaluronic acid and microneedle patch technology, applied in the field of skin care products, can solve the problems of unfavorable penetration into the skin, insufficient mechanical strength of microneedles, unfavorable microneedle preparation and forming, etc., and achieve increased fluidity, high safety, and biological good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

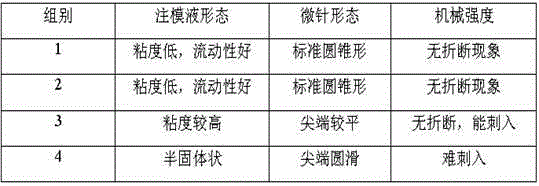

[0030] The influence of embodiment 1 hyperbranched polysulfone amine group hyaluronic acid molecular weight

[0031] The experiment was divided into four groups from 1 to 4. First, take four parts of hyperbranched polysulfone amine (molecular weight: 20kDa), 2g each, and dissolve them in 50g of water for injection under stirring at 30°C, then take 10g of hyaluronic acid with four different molecular weights, each with a molecular weight of 10kDa , 400kDa, 1000kDa and 1500kDa, respectively marked as 1, 2, 3, 4 groups, respectively slowly, while stirring, add the water dissolved in hyperbranched polysulfone amine, then add 0.2g of Vc glycoside, stir at 30 ℃ until completely Dissolved to obtain a clear solution. Vacuumize the solution to remove air bubbles to obtain the injection molding solution. Pour the above solution into a microneedle mold containing a large number of conical microholes. The diameter of the bottom of the conical hole is 300 μm and the depth is 600 μm. Then...

Embodiment 2

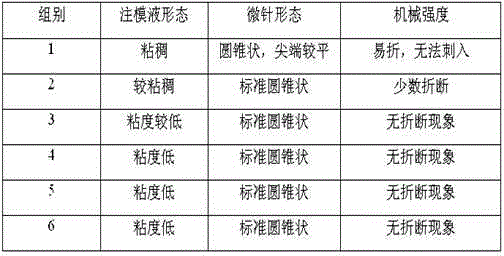

[0034] The influence of embodiment 2 hyperbranched polysulfone amine addition amount

[0035] There were 6 groups in the experiment, of which the first group was the negative control group, that is, no hyperbranched polysulfone amine was added, and the remaining five groups were added with different amounts of hyperbranched polysulfone amine (molecular weight 20kDa). The specific operation is as follows, six parts of 50g water for injection are added with different amounts of hyperbranched polysulfone amine, the weights are respectively 0g, 0.1g, 0.5g, 1.0g, 2.0g and 3.0g, respectively marked as 1, 2, 3, Groups 4, 5, and 6 were completely dissolved under stirring at 40°C, and then slowly added 10 g of hyaluronic acid (molecular weight 100 kDa) while stirring, and 0.2 g of Vc glycoside respectively. . Pour the above solution into a microneedle mold containing a large number of conical micropores. The diameter of the bottom edge of the conical hole is 300 μm, and the depth is 6...

Embodiment 3

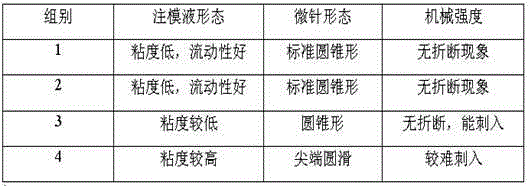

[0038] The influence of embodiment 3 hyperbranched polyester group hyaluronic acid molecular weight

[0039]The experiment was divided into four groups from 1 to 4. First, take four parts of hyperbranched polyester (molecular weight 5kDa, containing hydroxyl groups at the end), each 1g, dissolve in 50g water for injection under stirring at 50°C, and then take four hyaluronic acids with different molecular weights 10g each, molecular weight They are respectively 20kDa, 500kDa, 1500kDa and 2500kDa, respectively recorded as 1, 2, 3, 4 groups, respectively, slowly, while stirring, add 0.1g arbutin in water dissolved in hyperbranched polysulfone amine, and then add 0.1g arbutin respectively, 50 °C and stirred until completely dissolved to obtain a clear solution. Vacuumize the solution to remove air bubbles to obtain the injection molding solution. Pour the above solution into a microneedle mold containing a large number of conical microholes. The diameter of the bottom of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com