Coaxial electrostatic spinning fibrous scaffold and preparation method thereof

A technology of coaxial electrospinning and fiber support, which is applied in fiber processing, rayon manufacturing, fiber chemical characteristics, etc., to achieve the effects of simple method, prolonged release and absorption time, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] An embodiment of the present invention provides a coaxial electrospun fiber scaffold 5 , which includes: an aliphatic polyester shell layer 51 and a polyvinylpyrrolidone core layer 52 .

[0046] The embodiment of the present invention provides a coaxial electrospun fiber scaffold 5 comprising an aliphatic polyester shell layer 51 and a polyvinylpyrrolidone core layer 52 . Since polyvinylpyrrolidone is a safe and non-toxic water-soluble pharmaceutical intermediate and pharmaceutical adjuvant, it can be miscible or compounded with various substances, making the coaxial electrospun fiber scaffold 5 safe and non-toxic and has excellent biocompatibility ; Because the N-H or O-H bond of polyvinylpyrrolidone can form intermolecular associations with various drugs and / or bioactive factors, and control the release time and action intensity of drugs and / or bioactive factors through the association, Prolonging the release and absorption time of the drug and / or bioactive factor in ...

Embodiment 2

[0048] The present invention provides a coaxial electrospinning fiber scaffold 5, the coaxial electrospinning fiber scaffold 5 includes: an aliphatic polyester shell layer 51 and a polyvinylpyrrolidone core layer 52 loaded with drugs and / or bioactive factors .

[0049] By adding drugs and / or bioactive factors to the polyvinylpyrrolidone core layer 52, the prepared coaxial electrospun fiber scaffold 5 has a medicinal function, and can be used for directional treatment of patients.

[0050] Specifically, the aliphatic polyester is at least one selected from polycaprolactone, polylactic acid, polylactic acid-glycolic acid copolymer, and poly(lactic acid-hexanol) copolymer, preferably polycaprolactone.

[0051] Based on the requirements for the biodegradability, mechanical properties and processability of the shell, the shell material of the fiber scaffold in the embodiment of the present invention is selected from polycaprolactone, polylactic acid, polylactic acid-glycolic acid cop...

Embodiment 3

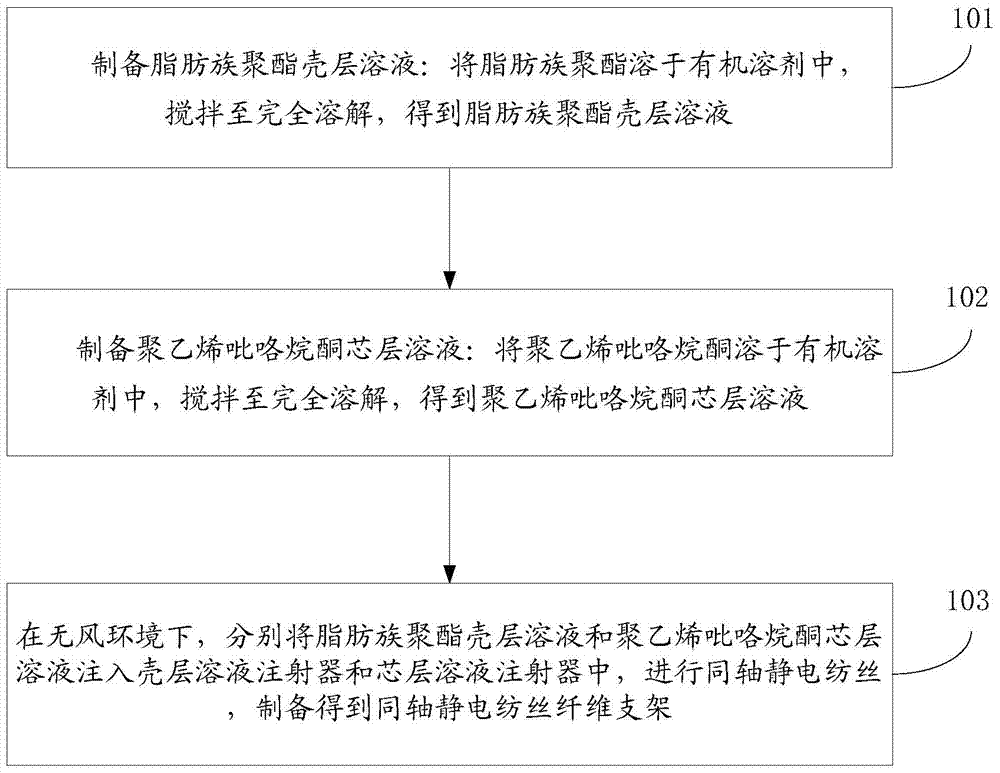

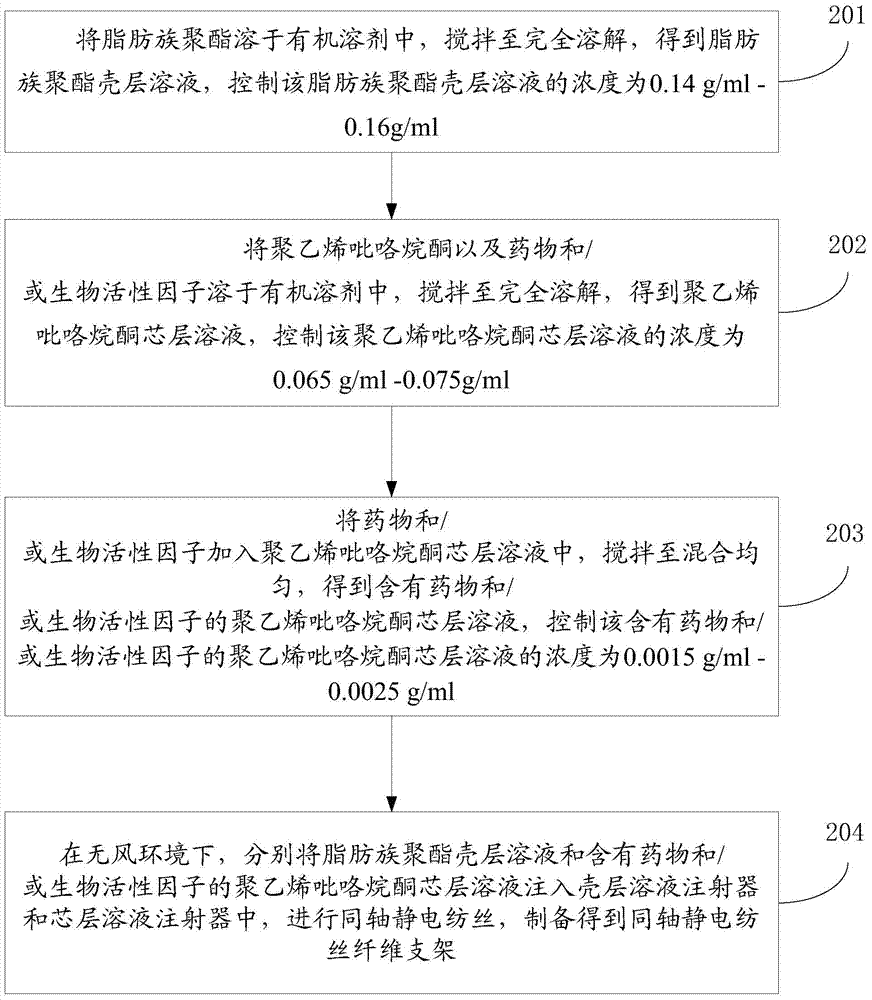

[0058] as attached figure 1 As shown, the embodiment of the present invention provides a method for preparing a coaxial electrospun fiber scaffold, including:

[0059] Step 101: preparing an aliphatic polyester shell solution: dissolving the aliphatic polyester in an organic solvent and stirring until completely dissolved to obtain an aliphatic polyester shell solution.

[0060] Step 102: preparing a polyvinylpyrrolidone core layer solution: dissolving the polyvinylpyrrolidone in an organic solvent and stirring until completely dissolved to obtain a polyvinylpyrrolidone core layer solution.

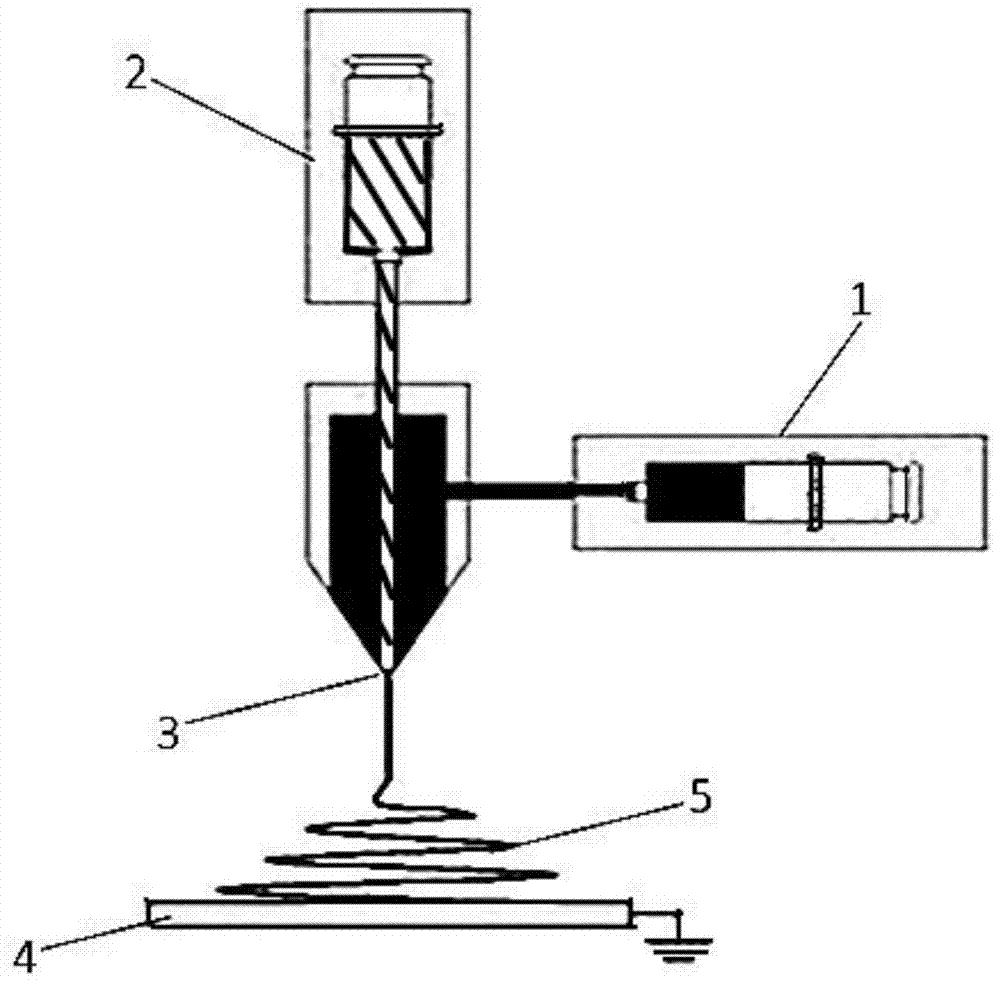

[0061] Step 103: In a windless environment, inject the aliphatic polyester shell solution and the polyvinylpyrrolidone core solution into the shell solution injector 1 and the core solution injector 2 respectively, and perform coaxial electrospinning to prepare a coaxial Electrospun fiber scaffolds5.

[0062] The preparation method of the coaxial electrospinning fiber scaffold 5 provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com