Coaxial electrostatic spinning fibrous scaffold and preparation method thereof

A technology of coaxial electrospinning and fiber scaffolding, which is applied in spinning solution preparation, fiber processing, filament/thread forming, etc., can solve the problems of few BMSCs and weak differentiation ability, and achieve effective and rapid repair and promotion of cartilage The effect of direction differentiation, safety, non-toxicity and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

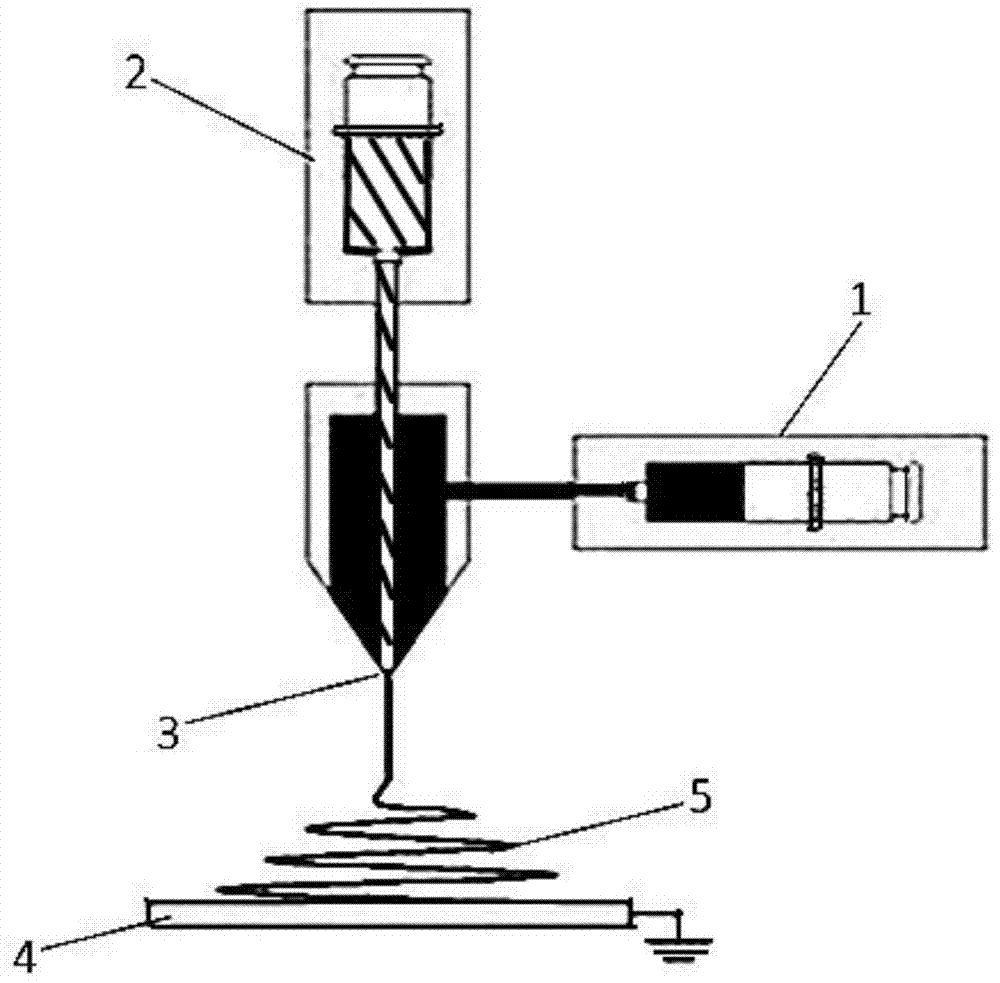

[0049] The embodiment of the present invention provides a coaxial electrospun fiber scaffold 5, the fiber scaffold includes an aliphatic polyester shell layer 51 and a polyvinylpyrrolidone core layer 52, the surface of the aliphatic polyester shell layer 51 is coupled with bone marrow Mesenchymal stem cell affinity peptide, the polyvinylpyrrolidone core layer 52 is loaded with recombinant human transforming growth factor-β1.

[0050] An embodiment of the present invention provides a coaxial electrospun fiber scaffold 5, which includes an aliphatic polyester shell 51 coupled with a bone marrow mesenchymal stem cell affinity peptide and a polysaccharide loaded with recombinant human transforming growth factor-β1. Vinylpyrrolidone core layer 52 . Through the combination of the aliphatic polyester shell layer 51 and the polyvinylpyrrolidone core layer 52, not only the fiber scaffold has the characteristics of safety, non-toxicity and excellent biocompatibility, but also the fiber ...

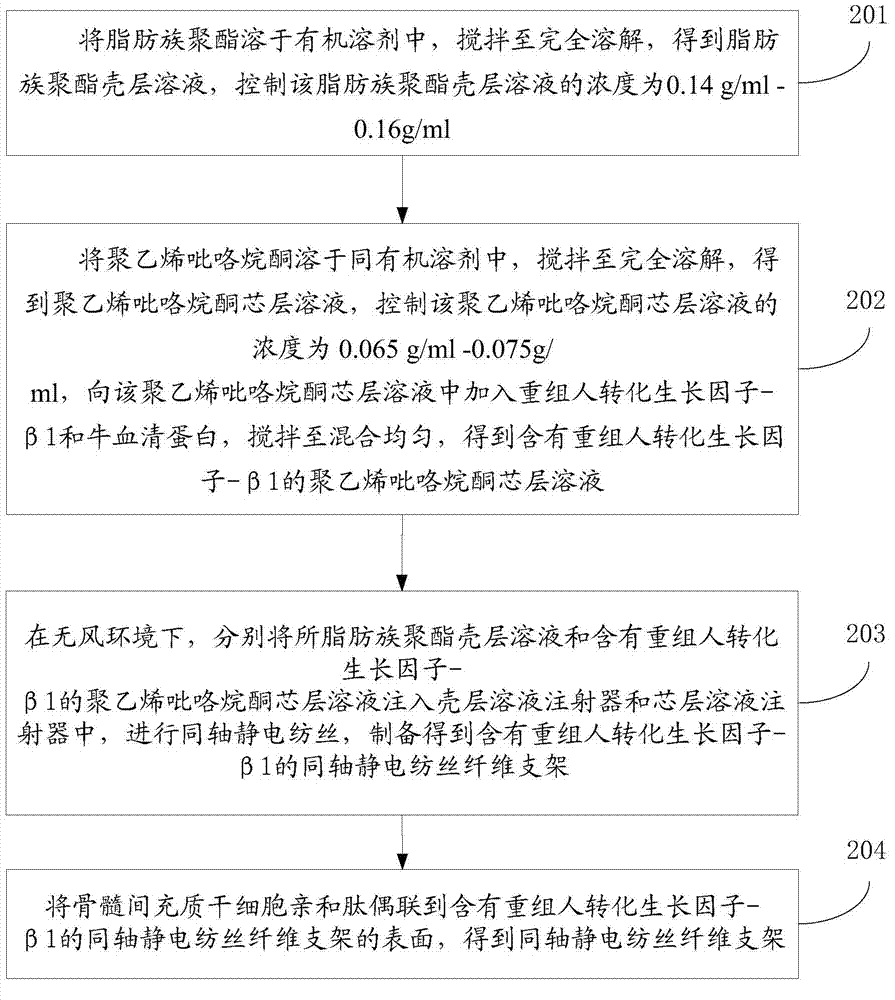

Embodiment 2

[0052] The embodiment of the present invention provides a coaxial electrospun fiber scaffold 5, the fiber scaffold includes an aliphatic polyester shell layer 51 and a polyvinylpyrrolidone core layer 52, the surface of the aliphatic polyester shell layer 51 is coupled with bone marrow Mesenchymal stem cell affinity peptide, the polyvinylpyrrolidone core layer 52 is loaded with recombinant human transforming growth factor-β1 and bovine serum albumin.

[0053] Since polyvinylpyrrolidone is a safe and non-toxic water-soluble pharmaceutical intermediate and pharmaceutical adjuvant, it can be miscible or compounded with various substances, making the coaxial electrospun fiber scaffold 5 safe and non-toxic and has excellent biocompatibility ; Because the N-H or O-H bond of polyvinylpyrrolidone can form intermolecular associations with various drugs and / or bioactive factors, and control the release time and action intensity of drugs and / or bioactive factors through the association, P...

Embodiment 3

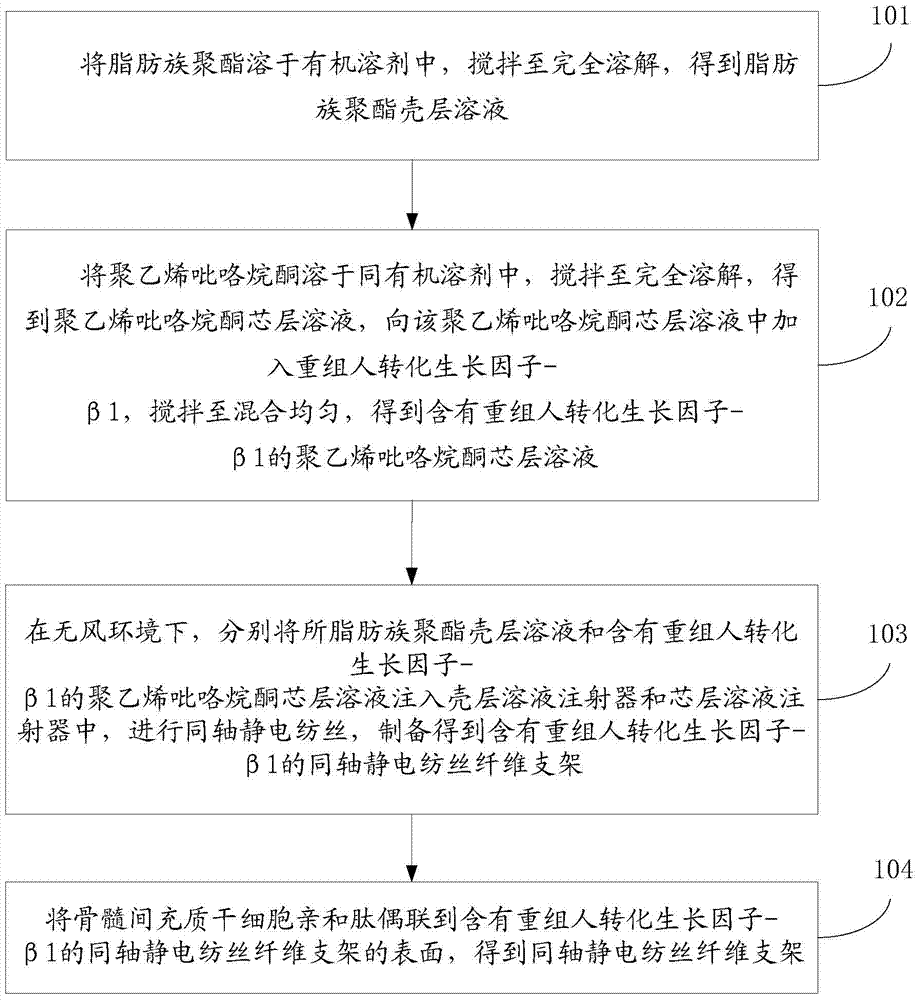

[0063] as attached figure 1 As shown, the embodiment of the present invention provides a method for preparing a coaxial electrospun fiber scaffold 5, including:

[0064] Step 101: preparing an aliphatic polyester shell solution: dissolving the aliphatic polyester in an organic solvent and stirring until completely dissolved to obtain an aliphatic polyester shell solution.

[0065] Step 102: Prepare a polyvinylpyrrolidone core layer solution containing recombinant human transforming growth factor-β1: dissolve polyvinylpyrrolidone in the same organic solvent, stir until completely dissolved to obtain a polyvinylpyrrolidone core layer solution, and add the polyvinylpyrrolidone core layer solution to the polyvinylpyrrolidone core layer solution Add recombinant human transforming growth factor-β1 into the layer solution, stir until mixed evenly, and obtain polyvinylpyrrolidone core layer solution containing recombinant human transforming growth factor-β1.

[0066] Step 103: In a w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com