System for controlling electrostatic level in fluidized bed

A fluidized bed and horizontal technology, applied in the direction of chemical/physical processes, chemical instruments and methods, etc., can solve problems such as high difficulty in implementation, narrow adjustment range of static electricity level, and ineffective static elimination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

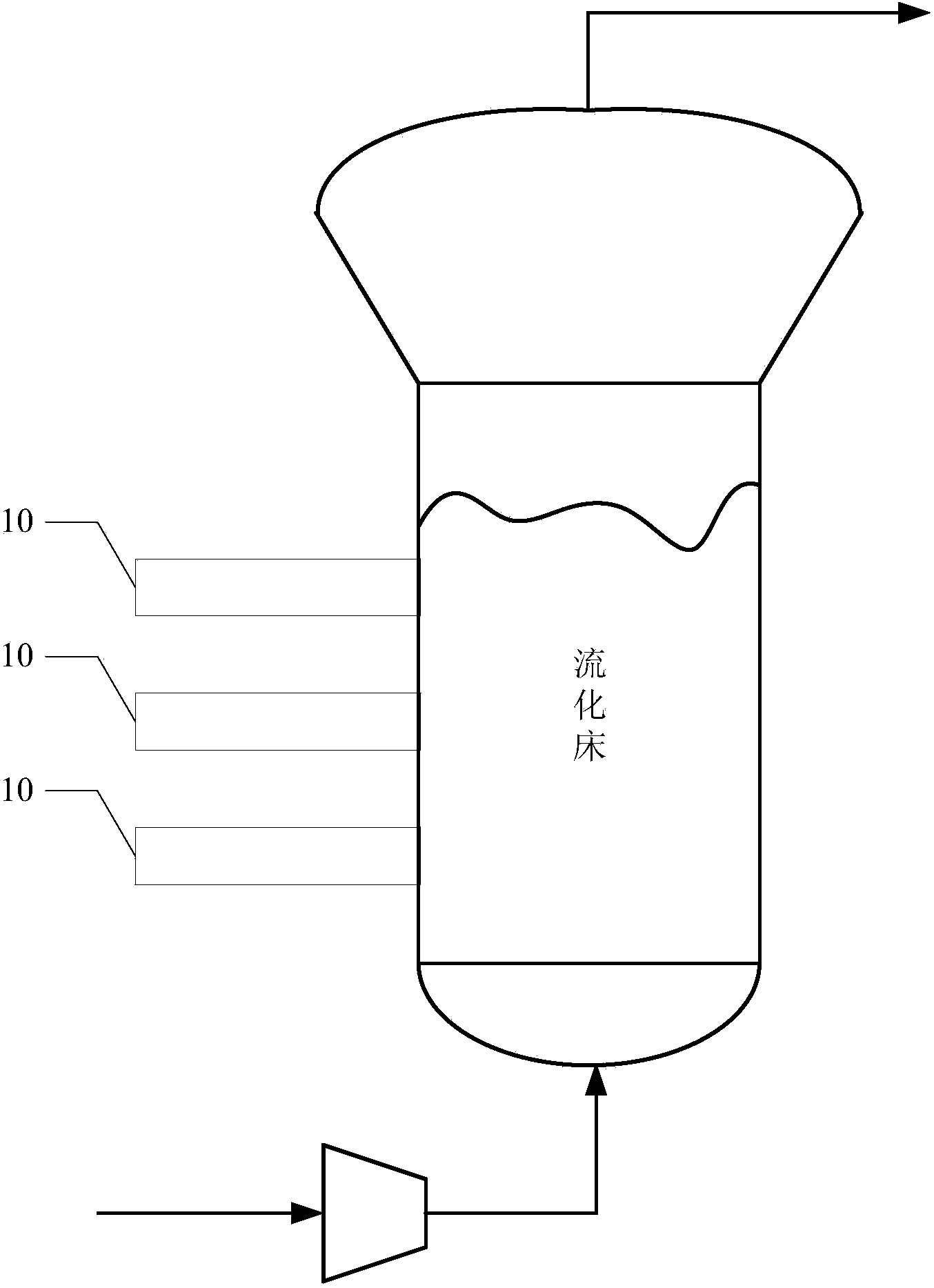

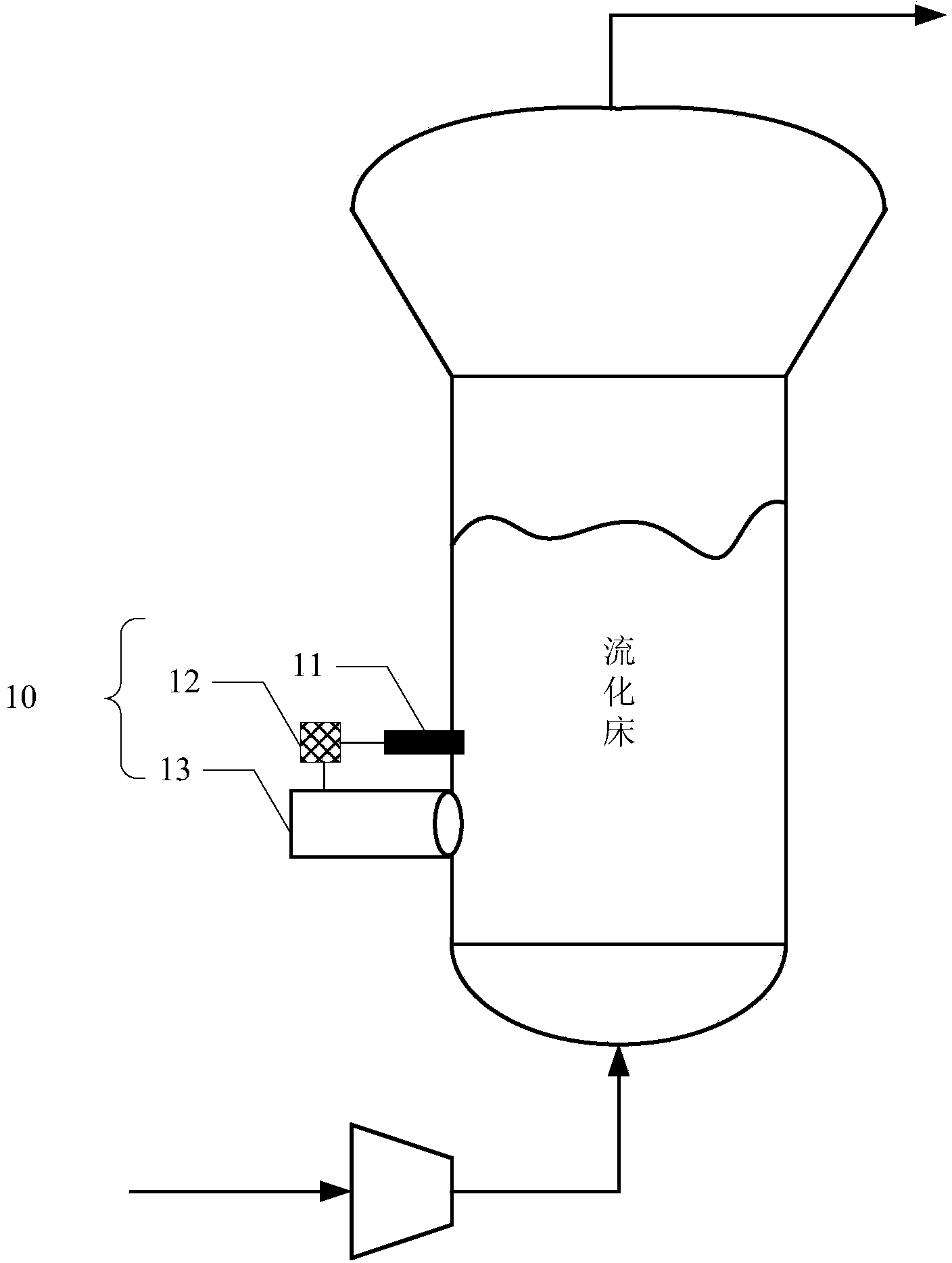

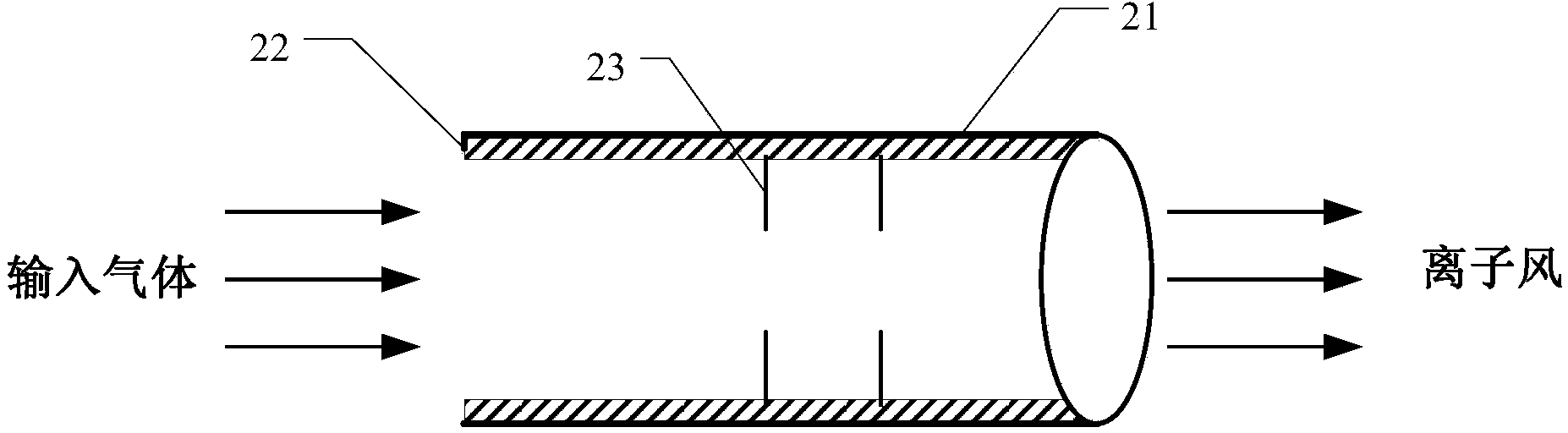

[0056] In a plexiglass fluidized bed with a height of 2000mm and an inner diameter of 420mm, linear low-density polyethylene (LLDPE) is used as the fluidized particles, the height of the static bed is 440mm, and compressed air is used as the fluidizing gas, and the superficial gas velocity during fluidization is 0.7 m / s. The electrostatic potential in the fluidized bed is measured using electrostatic measuring equipment, which is installed at 300mm and 500mm above the distribution plate of the fluidized bed. The 4-20mA current signal output by the electrostatic measuring equipment is input to the controller for storage and subsequent processing after analog-to-digital conversion. Ion wind equipment adopts figure 2 In the structure shown, four needle-like electrodes are placed in a staggered manner, and two needle-shaped electrodes are respectively arranged at 2cm and 12cm away from the outlet of the gas delivery pipeline. The ion wind equipment is installed on both sides of ...

Embodiment 2

[0059] In a plexiglass fluidized bed with a height of 1500mm and an inner diameter of 400mm, linear low-density polyethylene (LLDPE) is used as fluidized particles, the height of the static bed is 250mm, compressed air is used as the fluidized gas, and the superficial gas velocity during fluidization is 0.5 m / s. Use electrostatic measuring equipment to measure the electrostatic potential in the fluidized bed, and the electrostatic measuring equipment is installed 300mm above the distribution plate of the fluidized bed. The 4-20mA current signal output by the electrostatic measuring equipment is input to the controller for storage and subsequent processing after analog-to-digital conversion. Ion wind equipment adopts figure 2 In the structure shown, four needle-like electrodes are placed in a staggered manner, and two needle-shaped electrodes are respectively arranged at 2cm and 12cm away from the outlet of the gas delivery pipeline. The ion wind equipment is located 300mm ab...

Embodiment 3

[0062] In a plexiglass fluidized bed with a height of 2000mm and an inner diameter of 420mm, linear low-density polyethylene (LLDPE) is used as fluidized particles, the height of the static bed is 320mm, compressed air is used as the fluidized gas, and the superficial gas velocity during fluidization is 0.7 m / s. Use electrostatic measuring equipment to measure the electrostatic potential in the fluidized bed, and the electrostatic measuring equipment is installed at 400mm above the distribution plate of the fluidized bed. The 4-20mA current signal output by the electrostatic measuring equipment is input to the controller for storage and subsequent processing after analog-to-digital conversion. Ion wind equipment adopts figure 2In the structure shown, a layer of insulating plate is set 4cm away from the outlet of the gas delivery pipeline, and 8 needle-shaped electrodes are evenly arranged on the insulating plate. The needle-shaped electrodes are perpendicular to the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com