Bamboo filament biological membrane seriously polluted riverway water restoring device and method

A technology for heavy pollution and biofilm, which is applied in the field of nitrogen pollutants, suspended bacteria and particulate matter, and in the field of purifying organic matter in heavily polluted water bodies. poor biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

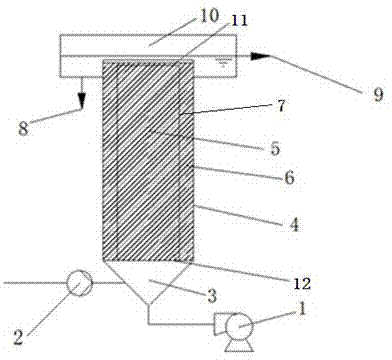

[0027] like figure 1 Shown, a kind of repairing device of bamboo silk biofilm repairing heavily polluted river course water body comprises housing 4, and the upper dividing plate 11, the lower dividing plate 12 with mesh are installed respectively in the upper part and the lower part in the housing 4, upper dividing plate Both the plate 11 and the lower dividing plate 12 are stainless steel mesh plates, and they are mainly used for fixing bamboo wire fillers. The lower partition 12 divides the inner cavity of the housing 4 into two parts, the main reaction zone and the gas-water mixing zone 3, and the main reaction zone is installed with a guide tube 7, which divides the main reaction zone into an air-water upflow zone 5 and the inside and outside of the downflow area 6, the guide tube can be a cylinder or a square tube or a polygonal tube. The main reaction area is filled with bamboo silk filler, and a sedimentation area 10 is installed on the top of the shell 4, and a water...

Embodiment 2

[0034] The difference between the repair device of Example 2 and Example 1 is that the volume ratio of the air-water mixing zone, the main reaction zone and the precipitation zone is 1:4.5:2.

[0035] The bamboo silk filler in the repairing device of this embodiment is the bamboo silk filler that has been processed by the following method: the bamboo silk filler of moso bamboo is made into a cuboid shape, then soaked continuously for 7 days with 10% sodium hydroxide aqueous solution, and the hydrogen oxidizer is replaced every day. Sodium aqueous solution, after soaking, rinse with distilled water for 5 times; then dry it to remove the water-soluble substances in the bamboo fiber filler; finally spread the dried bamboo fiber filler in a single layer, under the ultraviolet light of 240-270nm wavelength, the distance Ultraviolet light was irradiated for 40min at 15cm to reduce the crystallinity in the bamboo silk filler. The specifications of the bamboo wire filler are: length 3...

Embodiment 3

[0039] The difference between the repair device of Example 3 and Example 1 is that the volume ratio of the air-water mixing zone, the main reaction zone and the precipitation zone is 1:3:1.8.

[0040] The bamboo silk filler in the repairing device of this embodiment is the bamboo silk filler that has been processed through the following method: Moso bamboo is made into a cuboid-shaped filamentous bamboo, then soaked continuously for 6 days with 7% sodium hydroxide aqueous solution, and the hydrogen oxidizer is replaced every day. Sodium aqueous solution, rinse with tap water four times after soaking; then dry in a blast drying oven with a temperature not exceeding 60°C to remove water-soluble substances in the bamboo silk filler; finally spread the dried bamboo silk filler in a single layer , under the ultraviolet light of 240-270nm wavelength, ultraviolet irradiation is carried out for 28min at a distance of 12cm from the ultraviolet lamp, so as to reduce the crystallinity in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com