Novel process of rock debris wastewater treatment

A wastewater treatment and process technology, which is applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as complex water quality components, highly dispersed drilling wastewater, and large changes in water quality and quantity. To achieve the effect of improving the utilization rate of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Now the specific embodiment of the new technology for the treatment of cuttings waste water is described in the following. The following examples are illustrative, not restrictive, and should not be used to limit the protection scope of the present invention.

[0021] The present invention will be described below in conjunction with the drawings and specific embodiments.

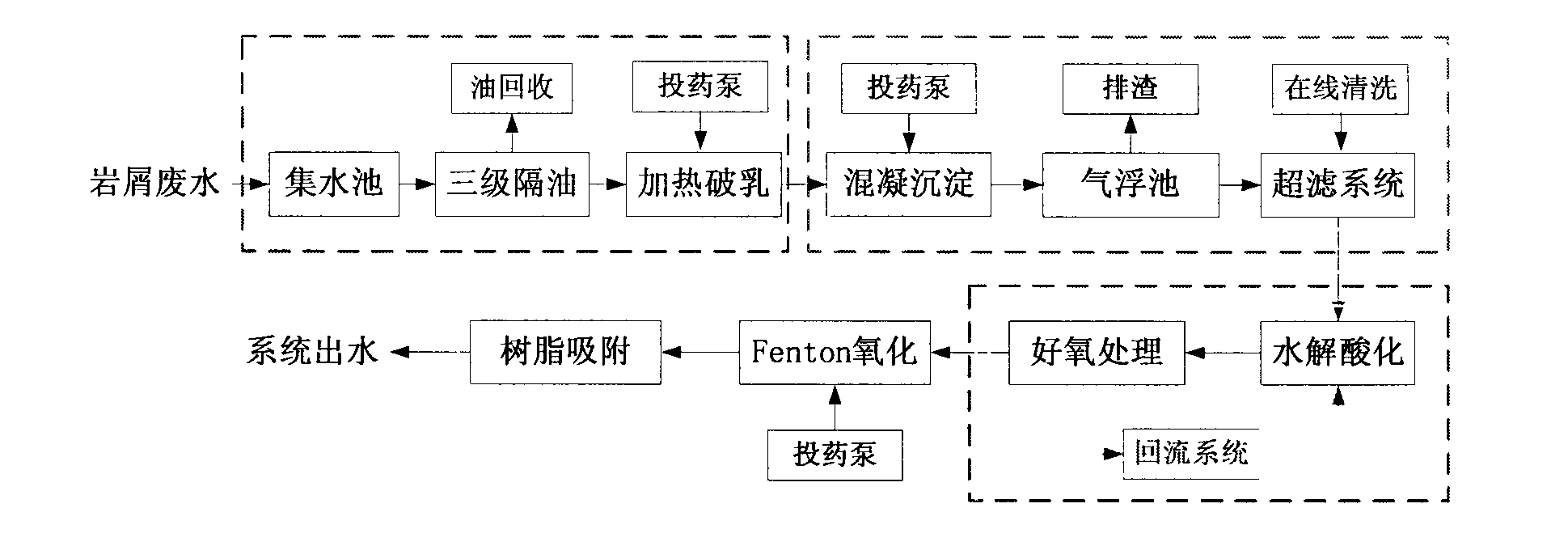

[0022] The new technology of cuttings waste water treatment of the present invention is aimed at the water quality characteristics of high oil content, high COD, high turbidity and chroma of cuttings waste water, and uses the pretreatment unit to recover and remove a large amount of oil in the waste water, and the physical and chemical unit removes most of COD and SS And ammonia nitrogen, and further remove oil, the biochemical treatment unit relies on the decomposition of microorganisms to remove BOD, COD and ammonia nitrogen, and the advanced treatment unit is for further treatment of higher effluen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com