Method for comprehensively recycling such valuable metals as iron, aluminum, scandium, titanium, vanadium and the like in red mud

A technology for recovering valuable metals and iron, applied in the direction of improving process efficiency, etc., can solve problems such as difficulty, poor economy, difficult industrial application, etc., and achieve the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

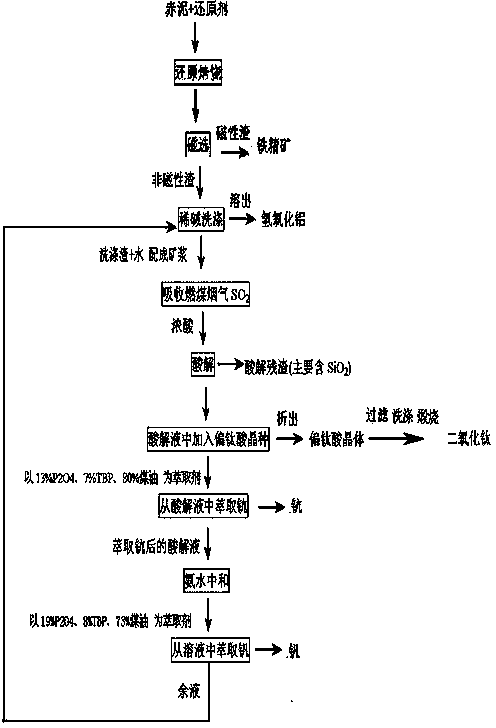

Image

Examples

Embodiment 1

[0013] 1) Mix 50kg of red mud with 25kg of coal ash for magnetization roasting to make Fe 2 o 3 converted to Fe 3 o 4 ;(2) Magnetic iron concentrate and non-magnetic products are obtained through magnetic separation, wherein the recovery rate of iron concentrate is 94%, and the iron content is >90%; (3) Non-magnetic products are dissolved with dilute alkali to dissolve alumina; Washing slag and 50 liters of water are mixed into a slurry, which is used as an absorbent to absorb SO in coal-fired flue gas 2 . In this process, the alkali in the washing slag is replaced by SO 2 Neutralize and dissolve, and the pH can be reduced to 5; (5) Add 90% H to the washing residue 2 SO 4 Carry out acidolysis, dissolve scandium and titanium in the acidolysis solution, and the acidolysis residue contains SiO 2 , can be directly used in the production of cement and refractory materials; (6) The acid solution is heated to between 90°C and 100°C, and metatitanic acid seeds are added, and ti...

Embodiment 2

[0016] 1) Combine 40kg red mud with 20m 3 Coal gas is mixed for magnetization roasting, so that Fe 2 o 3 converted to Fe 3 o 4 ;(2) Obtain magnetic iron concentrate and non-magnetic products through magnetic separation, in which the recovery rate of iron concentrate is 93%, and the iron content is >91%; (3) Non-magnetic products are dissolved with dilute alkali to dissolve alumina; Washing slag and 40 liters of water are mixed into a slurry, which is used as an absorbent to absorb SO in coal-fired flue gas 2 . In this process, the alkali in the washing slag is replaced by SO 2 Neutralize and dissolve, and the pH can drop to 7; (5) Add 90% H to the washing residue 2 SO 4 Carry out acidolysis, dissolve scandium and titanium in the acidolysis solution, and the acidolysis residue contains SiO 2 , can be directly used in the production of cement and refractory materials; (6) The acid solution is heated to between 90°C and 100°C, and metatitanic acid seeds are added, and tit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com