Technology for separating copper, zinc and iron in scrap copper smelting slag leaching process

A technology for smelting slag and waste miscellaneous copper, which is applied in the field of separation of copper, zinc and iron, can solve the problems of increasing the iron removal process and increasing the burden on enterprises, and achieves the effects of improving economic benefits, improving the level of comprehensive utilization of resources, and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

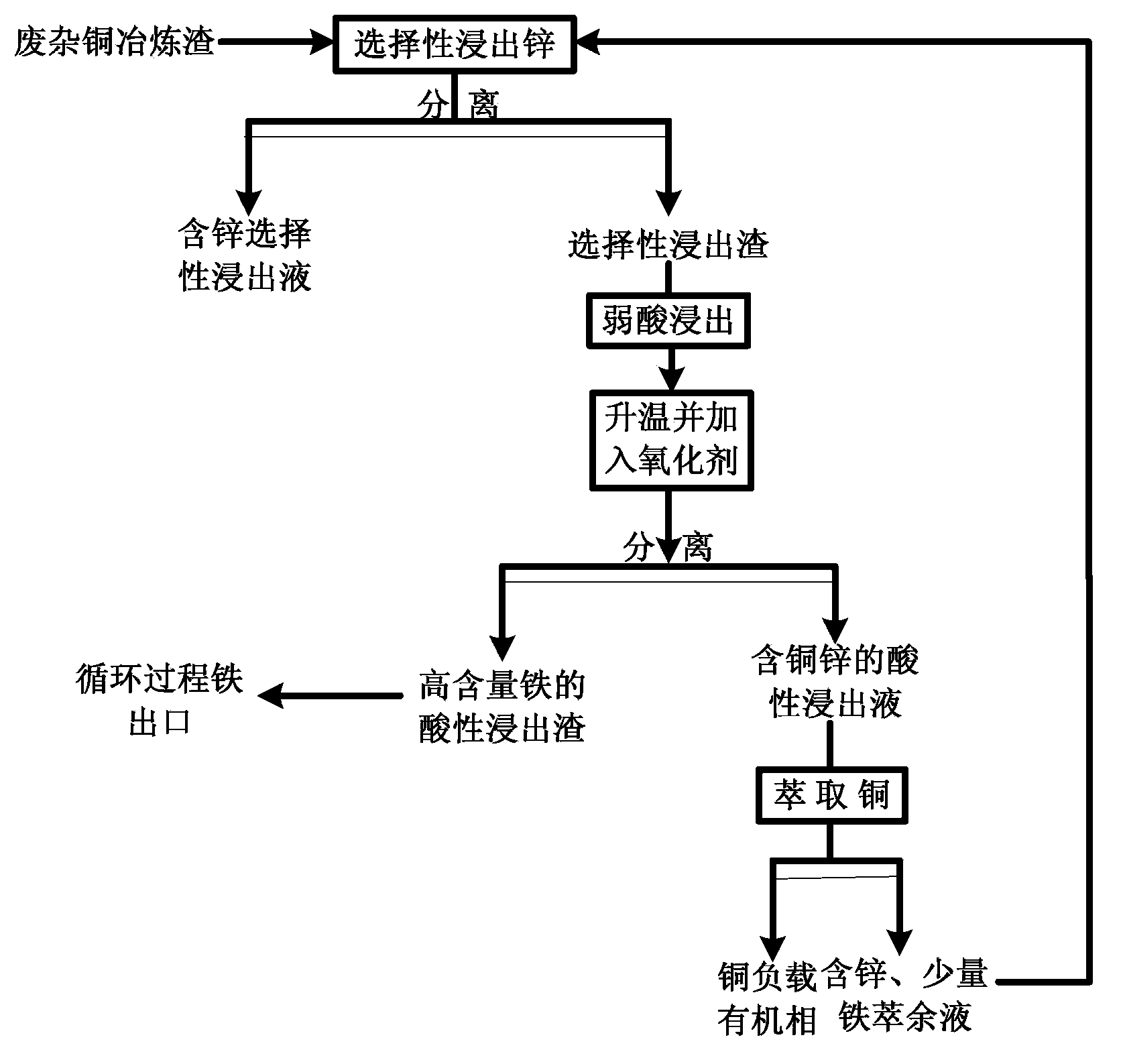

[0025] Below in conjunction with specific implementation examples the present invention will be further described, please refer to figure 1 , is the flow chart of copper-zinc and iron separation process in the leaching process of waste miscellaneous copper smelting slag of the present invention.

[0026] (1) Preparatory work for leaching

[0027] Take a large scrap copper smelting and recycling enterprise in my country as an example. The enterprise produces a large amount of waste miscellaneous copper smelting slag every year. The slag contains a large amount of copper, zinc and iron, and its occurrence state is mainly oxide and metal alloy state. Waste miscellaneous copper smelting slag has a wide particle size distribution and must be screened. The sieving limit is 60 mesh, and the part with large particle size is separated by sieving, and the part with small particle size passes through magnetic separation to recover part of the metal iron, and re-selects to recover metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com