Method for welding LED chip to ceramic body through ultrasonic waves at normal temperature

A LED chip and ultrasonic welding technology, which is applied in the manufacture of semiconductor devices, electric solid devices, semiconductor/solid devices, etc., can solve problems such as chip damage, impact on chip life, damage, etc., and achieve extended chip life, high practical value, and reduced There is the effect of lead pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

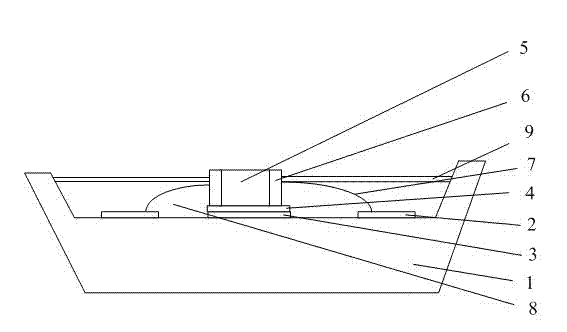

[0016] The purpose and effects of the present invention will become more apparent by describing the present invention in detail below in conjunction with the accompanying drawings and embodiments.

[0017] The method for normal-temperature ultrasonic welding of LED chips on a ceramic body of the present invention comprises the following steps:

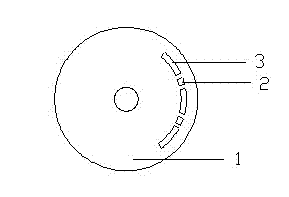

[0018] (1) Sintering palladium silver on the ceramic body 1 to form the soldering silver pad 2 and the thermally conductive silver pad 3, this step includes the following sub-steps:

[0019] (1.1) Screen printing: First, make templates for thermally conductive silver pads 2 and soldered silver pads 3, apply photosensitive glue on the screen, then put the template on the photosensitive glue, expose it through an exposure machine, and cover it with the template on the screen Exposure outside the part, the photosensitive glue is solidified, and the part covered by the template is opaque, and the photosensitive glue covered by the template...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com