Inversion organic thin film solar cell decorated by polar solvent and preparing method thereof

A solar cell and polar solvent technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of improving the conductivity of PEDOT:PSS thin films, restricting the carrier hole transport rate, and hindering carrier transport, etc. Achieve the effect of improving carrier transport efficiency, increasing carrier transport efficiency, and reducing recombination probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

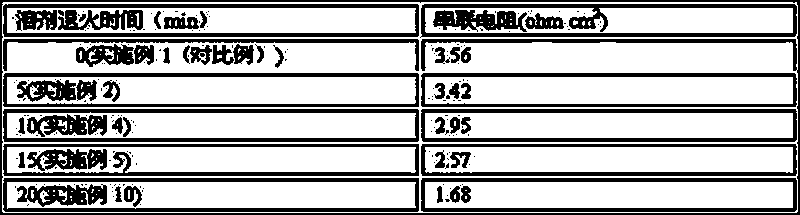

[0035] Embodiment 1 (comparative example):

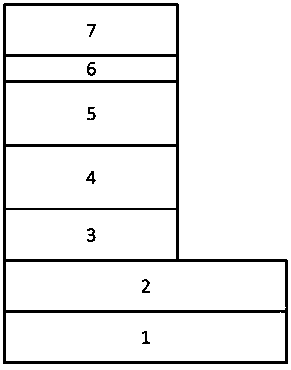

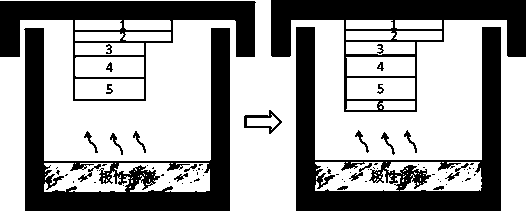

[0036] Clean the substrate composed of transparent substrate and transparent conductive cathode ITO with surface roughness less than 1 nm, and then dry it with nitrogen; spin-coat ZnO (5000 rpm, 40 s, 15 nm) on the surface of transparent conductive cathode ITO, and The formed film was baked (200°C, 60 min) to obtain a cathode buffer layer; a photoactive layer of P3HT:PCBM (1:20, 20 mg / ml) was prepared on the cathode buffer layer by spin coating (1000 rpm, 25 s , 220 nm), and baked (140°C, 5 min); spin-coat PEDOT:PSS solution (3000 rpm, 60 s, 30 nm) on the surface of the photoactive layer to prepare the anode buffer layer; Annealing was performed by heating annealing (150°C, 5 min); metal anode Ag (100 nm) was vapor-deposited on the anode solvent buffer layer. Under standard test conditions: AM 1.5, 100 mW / cm 2 , the open circuit voltage of the device was measured (V OC )=0.54 V, short-circuit current (J SC )=8.6 mA / cm 2 , fill ...

Embodiment 2

[0038]Clean the substrate composed of transparent substrate and transparent conductive cathode ITO with surface roughness less than 1 nm, and then dry it with nitrogen; spin-coat ZnO (5000 rpm, 40 s, 15 nm) on the surface of transparent conductive cathode ITO, and The formed film was baked (200°C, 60 min) to obtain a cathode buffer layer; a photoactive layer of P3HT:PCBM (1:20, 20 mg / ml) was prepared on the cathode buffer layer by spin coating (1000 rpm, 25 s , 220 nm), and baked (140°C, 5 min); spin-coat PEDOT:PSS solution (3000 rpm, 60 s, 30 nm) on the surface of the photoactive layer to prepare the anode buffer layer; on the surface of the anode buffer layer, use The polar solvent buffer layer was prepared by solvent evaporation annealing method (95 % dimethyl sulfoxide, 5 % ethanol, 5 nm, 5 min); the substrate was annealed by heating and annealing on a constant temperature hot stage (150 ° C, 5 min); Metal anode Ag (100 nm) was evaporated on the polar solvent buffer layer....

Embodiment 3

[0040] Clean the substrate composed of transparent substrate and transparent conductive cathode ITO with surface roughness less than 1 nm, and then dry it with nitrogen; spin-coat ZnO (5000 rpm, 40 s, 15 nm) on the surface of transparent conductive cathode ITO, and The formed film was baked (200°C, 60 min) to obtain a cathode buffer layer; a P3HT:PCBM (1:20, 20 mg / ml) photoactive layer (1000 rpm, 25 s, 220 nm), and baked (140°C, 5 min); spin-coat PEDOT:PSS solution on the surface of the photoactive layer to prepare an anode buffer layer (3000 rpm, 60 s, 28 nm); on the anode buffer layer The surface was prepared with a polar solvent buffer layer (96 % dimethyl sulfoxide, 4 % ethanol, 5 nm, 15 min) by solvent evaporation annealing method; the substrate was annealed by heating and annealing on a constant temperature hot stage (150 ° C, 5 min); Metal anode Ag (100 nm) was evaporated on the polar solvent buffer layer. Under standard test conditions: AM 1.5, 100 mW / cm 2 , the open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com