Silver-doped titanium dioxide aerogel coating preparation technology and equipment

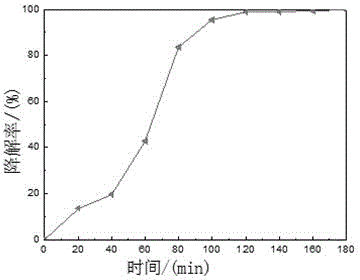

A technology of titanium dioxide and preparation process, which is applied in the field of preparation technology of silver-doped titanium dioxide airgel coating and equipment for preparing the coating on the substrate, can solve the problem of low utilization rate of silver and titanium dioxide, complex particle coating process, and relatively low utilization rate of silver and titanium dioxide. Low surface area and other problems, to achieve the effect of enhancing self-cleaning performance, inhibiting breeding and growth, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

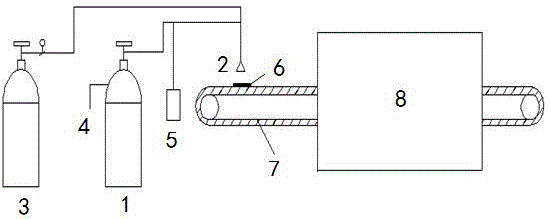

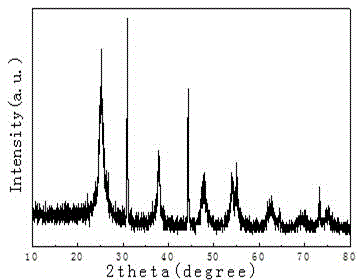

[0021] Preparation of silver-doped titanium dioxide nano-aqueous sol: using butyl titanate (Ti(OC 4 h 9 ) 4 ) as raw material, with glacial acetic acid (CH 3 COOH) and urea (CO(NH 2 ) 2 ) as catalyst, [BMIM]Br ionic liquid as co-solvent, absolute ethanol as solvent, and doped with 10% silver nitrate (AgNO 3 ) aqueous solution, and the silver-doped titania nano-hydrosol was prepared by the sol method. The molar ratio of each substance is butyl titanate (Ti(OC 4 h 9 ) 4 ): water: absolute ethanol: silver nitrate: glacial acetic acid (CH 3 COOH), urea (CO(NH 2 ) 2 ): ionic liquid = 1:5:10:0.1:0.01:0.04:1. Butyl titanate (Ti(OC 4 h 9 ) 4 ) and glacial acetic acid (CH 3 COOH), half of absolute ethanol and mixed evenly to form solution A, water, ionic liquid, urea (CO(NH 2 ) 2 ) and the other half of absolute ethanol to form solution B. Add solution B dropwise to solution A under vigorous stirring. After stirring for 60 minutes, add silver nitrate solution with a mo...

Embodiment 2

[0030] Embodiment 2: The preparation process of the silver-doped titanium dioxide airgel coating with self-cleaning function is prepared on the glass fiber decorative ceiling substrate, the steps are as follows:

[0031] Preparation of silver-doped titanium dioxide nano-aqueous sol: using butyl titanate (Ti(OC 4 h 9 ) 4 ) as raw material, with glacial acetic acid (CH 3 COOH) and urea (CO(NH 2 ) 2 ) as catalyst, [BMIM]Br ionic liquid as co-solvent, absolute ethanol as solvent, and doped with 10% silver nitrate (AgNO 3 ) aqueous solution, and the silver-doped titania nano-hydrosol was prepared by the sol method. The molar ratio of each substance is butyl titanate (Ti(OC 4 h 9 ) 4 ): water: absolute ethanol: silver nitrate: glacial acetic acid (CH 3 COOH), urea (CO(NH 2 ) 2 ): ionic liquid = 1:5:10:0.1:0.01:0.04:1. Butyl titanate (Ti(OC 4 h 9 ) 4 ) and glacial acetic acid (CH 3 COOH), half of absolute ethanol and mixed evenly to form solution A, water, ionic liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com