Abrasive grain saw blade and saw machine for dissociating abrasive cutting

A technology of free abrasives and abrasive grains, applied in the direction of fine working devices, working accessories, stone processing equipment, etc., can solve the problems of ineffective cutting of workpieces, reduced cutting line strength, and low cutting efficiency, so as to reduce daily consumption, The effect of reducing the cost of daily consumption and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

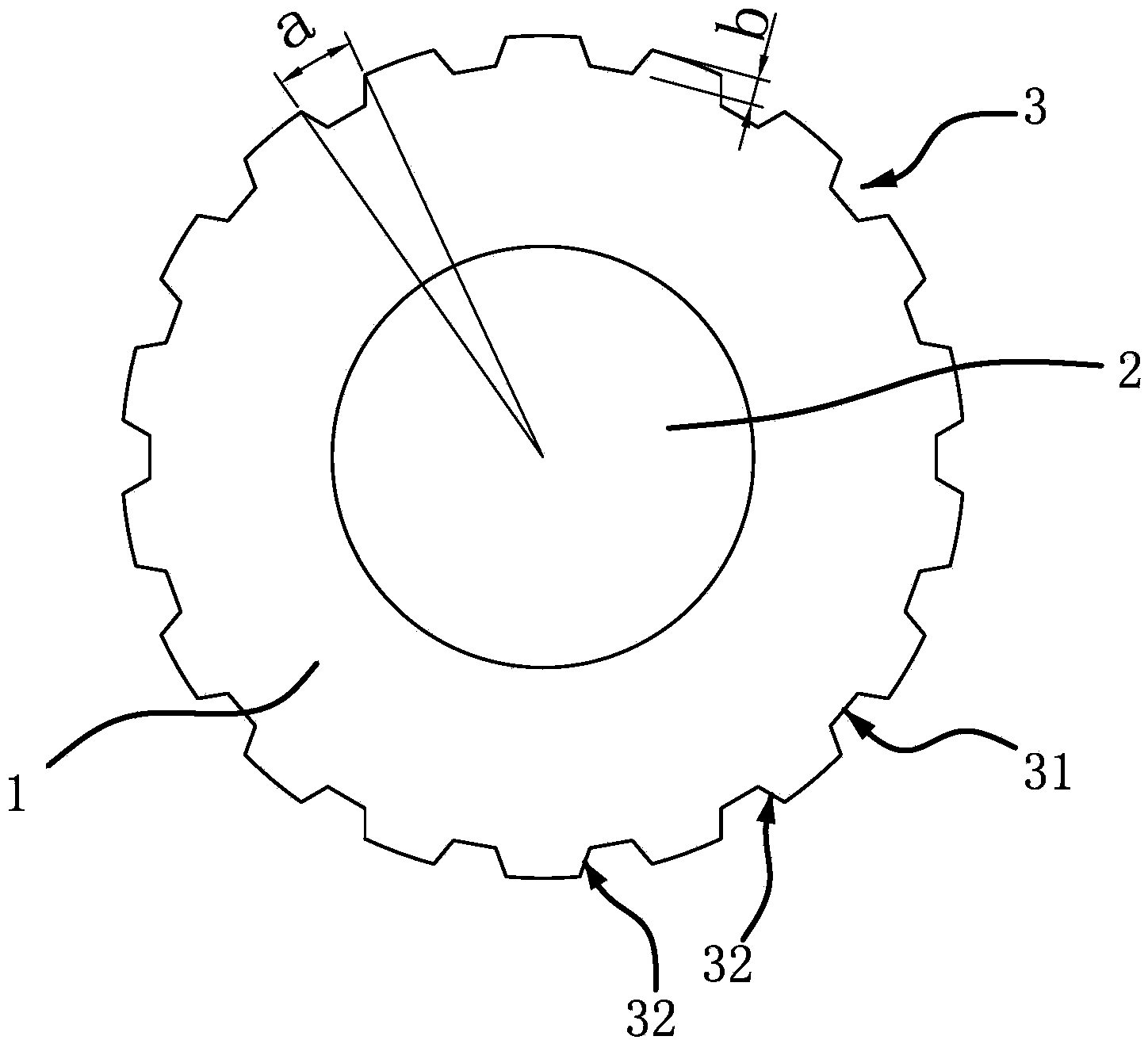

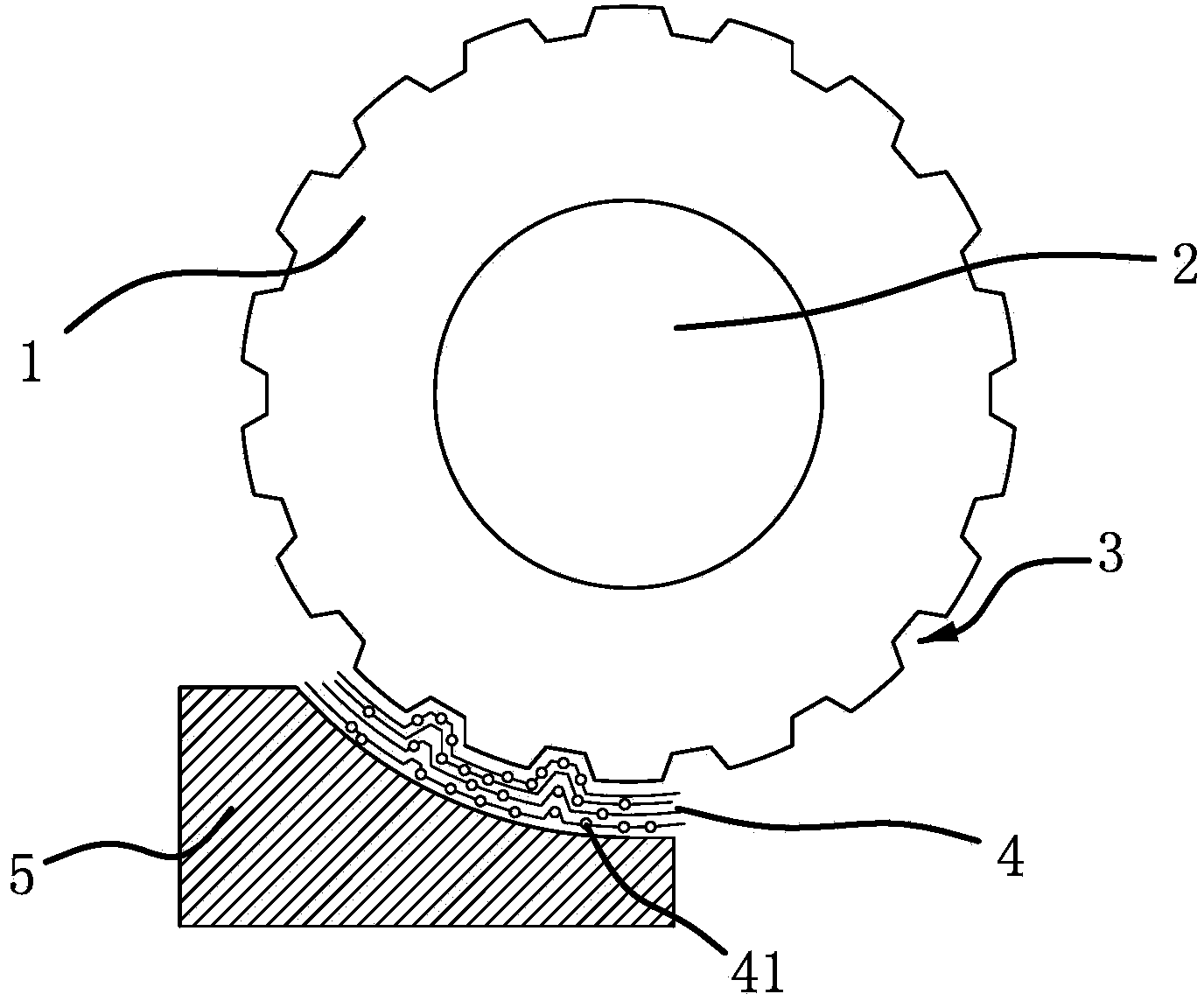

[0027] An abrasive saw blade for free abrasive cutting, such as figure 1 As shown, the cross-section of the abrasive saw blade 1 is circular, the center of the abrasive saw blade 1 has a fixing hole 2, and the outer peripheral surface of the abrasive saw blade 1 has a number of throwing notches 3 capable of accommodating free abrasive grains 41. The material rejection notches 3 are evenly distributed circumferentially on the outer peripheral surface of the abrasive grain saw blade 1, the center line of the material rejection notches 3 passes through the center of the fixing hole 2, and the material rejection notches 3 are symmetrical along the center line.

[0028] The opening of getting rid of material notch 3 has radian a, in the present embodiment one, as figure 1 As shown, the size of the radian a is π / 18, there are 18 material rejection notches 3, the thickness of the abrasive saw blade 1 is 0.02mm, the depth of the material rejection notch is b, and the radius of the abr...

Embodiment 2

[0036] The structure and principle of this embodiment are basically the same as that of the first embodiment, except that the radian a has a size of π / 144, 144 material rejection notches, and the thickness of the abrasive saw blade is 0.2 mm.

Embodiment 3

[0038] The structure and principle of this embodiment are basically the same as that of Embodiment 1, except that the radian a has a size of π / 81, 81 material rejection notches, and the thickness of the abrasive saw blade is 0.1 mm.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap