PHA (preliminary hazard analysis) anchor rod and construction method thereof

A construction method and bolt technology, which are applied in the directions of bolt installation, earthwork drilling, infrastructure engineering, etc., can solve the problems of long construction period, surrounding houses, road cracking, soil disturbance, etc., and achieve convenient construction and good effect. , the effect of reducing disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

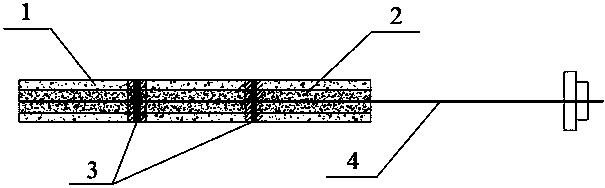

[0036] A PHA bolt, such as figure 1 As shown, the anchor rod body 4 is included, and the anchor rod body 4 is covered with a prefabricated tubular outer anchoring body 1 . The prefabricated tubular outer anchor 1 has a wall thickness of 25mm and an outer diameter of 150mm, and is formed by connecting multiple sections, each section is 1.5m long, and the adjacent sections are joined and fixed by connecting sleeves 3 .

[0037] Its construction method includes the following steps:

[0038] (1) Hole forming: use the built-in auger drill pipe to take soil and drill to form the pilot hole;

[0039] (2) Jack the prefabricated tubular outer anchor 1, and then continue to jack the steel casing at the outer end of the prefabricated tubular outer anchor 1;

[0040] (3) Implant the anchor body 4 in the prefabricated tubular outer anchor 1, pour high-grade cement slurry or cement mortar 2, and pull out the steel casing after the pouring is completed;

[0041] (4) pulp replenishment;

...

Embodiment 2

[0045] A PHA bolt, such as figure 1 As shown, the anchor body 4 is included, and the anchor body 1 is covered with a prefabricated tubular outer anchor 1 . The prefabricated tubular outer anchor 1 has a wall thickness of 40mm and an outer diameter of 180mm, and is formed by connecting multiple sections, each section is 1.5m long, and the adjacent sections are joined and fixed by connecting sleeves 3 .

[0046] Its construction method includes the following steps:

[0047] (1) Hole forming: use the auger drill pipe to drill the hole while injecting the cement slurry retaining wall, and inject the low-grade cement slurry while pulling out the drill pipe;

[0048] (2) Jack the prefabricated tubular outer anchor 1, and then continue to jack the steel casing at the outer end of the prefabricated tubular outer anchor 1;

[0049] (3) Implant the anchor body 4 in the prefabricated tubular outer anchor 1, pour high-grade cement slurry or cement mortar 2, and pull out the steel casing...

Embodiment 3

[0054] A PHA bolt, such as figure 1 As shown, the anchor rod body 4 is included, and the anchor rod body 4 is covered with a prefabricated tubular outer anchoring body 1 . The prefabricated tubular outer anchor 1 has a wall thickness of 30mm and an outer diameter of 160mm, and is formed by connecting multiple sections, each section is 1.5m long, and the adjacent sections are joined and fixed by connecting sleeves 3 .

[0055] Its construction method includes the following steps:

[0056] (1) Hole forming: Umbrella drilling tools are used to drill holes, and water is injected to replace the soil while drilling;

[0057] (2) While the drilling rig is drilling, the prefabricated tubular outer anchor 1 and the steel casing are sequentially jacked up. When the prefabricated tubular outer anchor 1 reaches the predetermined position, the drill pipe is pulled out and low-grade cement slurry is poured. It can be carried out when the end needs to be enlarged. Rotary jet reaming;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com