Conventional air-conditioning operating condition distributed phase change energy storage air conditioning system

A phase-change energy storage, conventional air-conditioning technology, applied in air-conditioning systems, heating and ventilation control systems, heating and ventilation safety systems, etc. The effect of high temperature, improving efficiency and saving electricity bills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] 1. Phase change energy storage materials

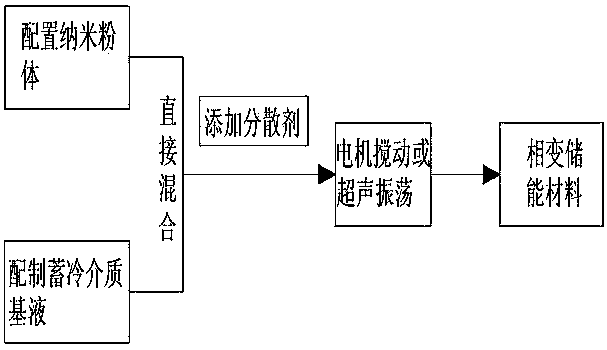

[0048] Refrigerant hydrate

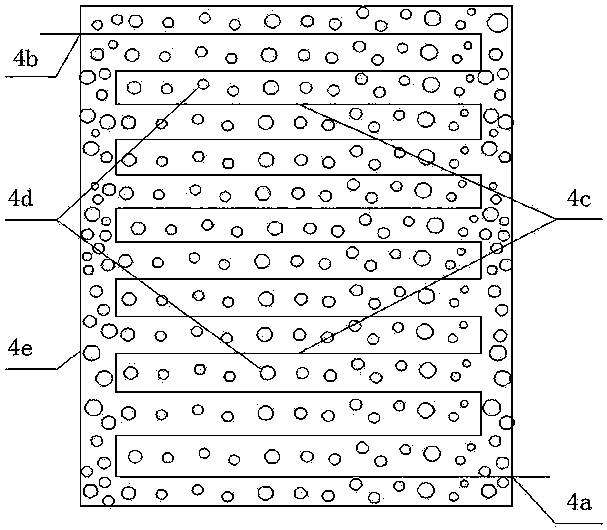

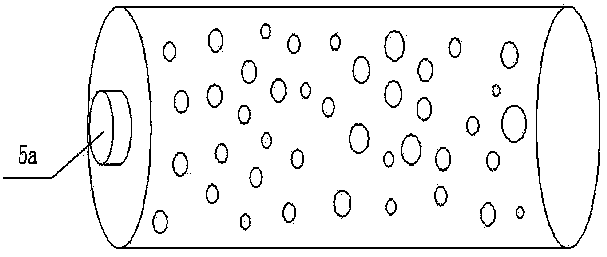

[0049] Using a three-step method, the first step is to add 0.2% nano-TiO 2 , 0.3% nano-Cu mixed to make nano-powder, the second step is to make 23.5% HCFC-14lb, 23.5% HFC-134, 47% water into cold storage medium base liquid, and then mix the above-mentioned nano-powder with cold storage medium base liquid liquid directly mixed to make nano-powder cold storage medium base liquid; in the third step, 3% ethylene glycol, 1% Tween-81, 1% octylphenol polyoxyethylene ether nonionic surfactant OP- 7 Mix to make a dispersant, and finally mix the nano-powder cold storage medium base liquid with the dispersant, and then make a suspended and stable refrigerant hydrate phase-change energy storage material after being agitated by a motor or super-vibrated. Distributed phase-change storage The energy device is filled with the phase change energy storage material (4d).

[0050] Organic phase change energy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com