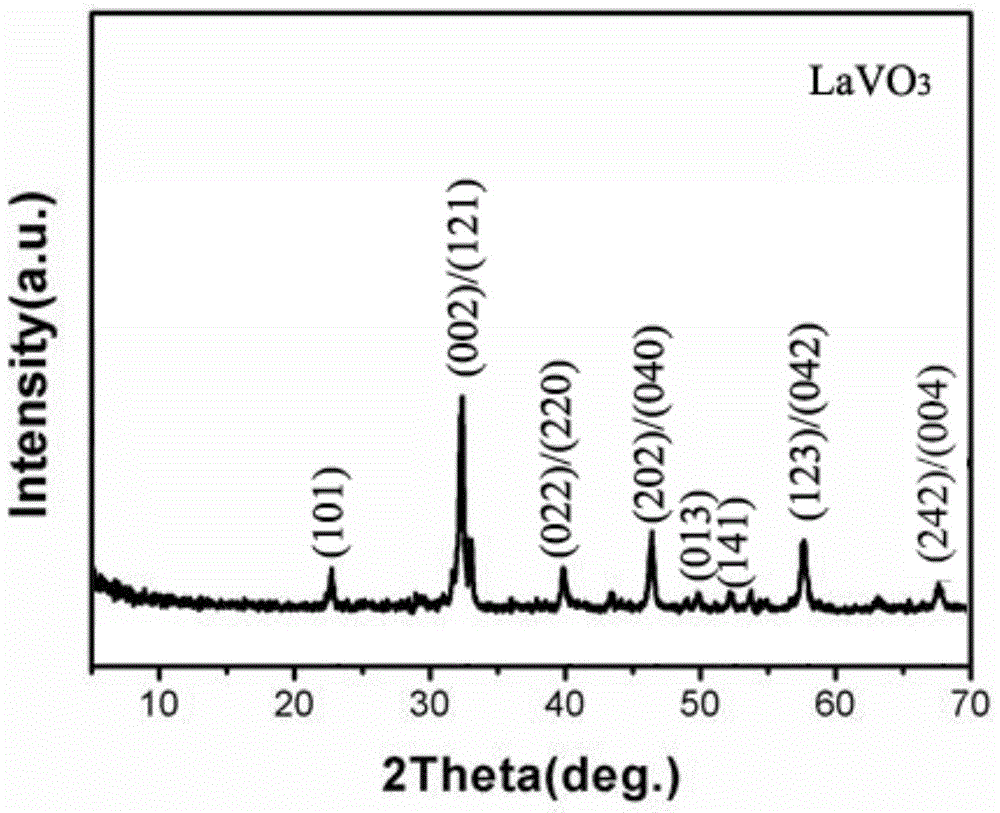

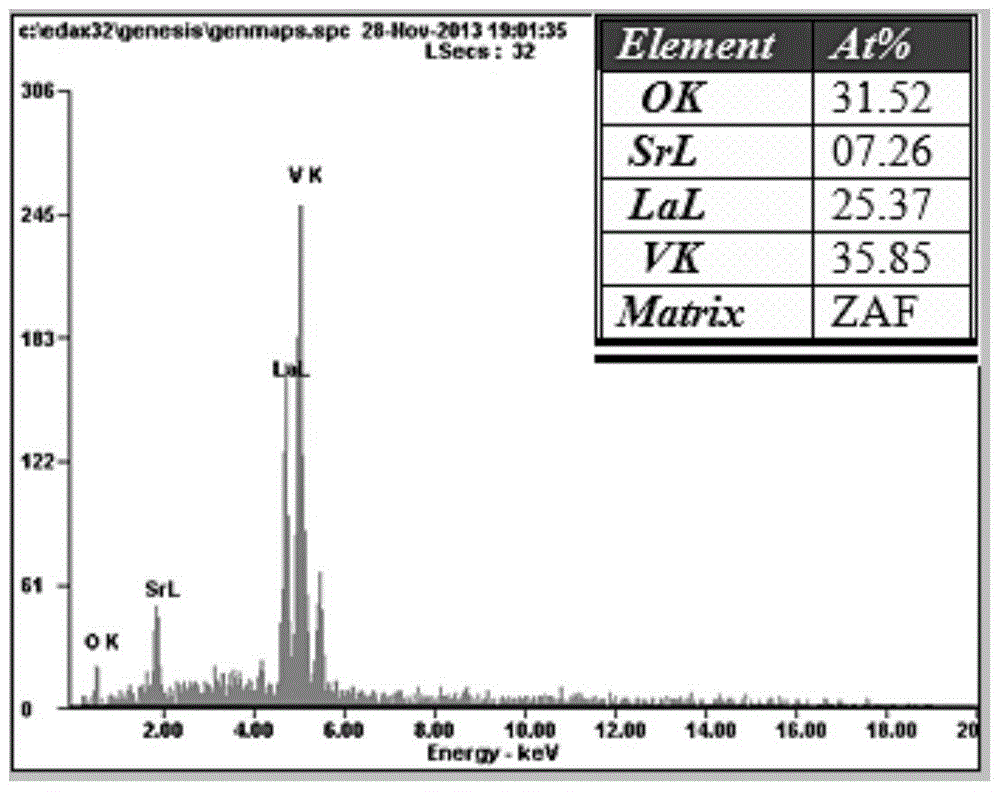

A strontium-doped lavo 3 Preparation method of nanowire and gas sensor thereof

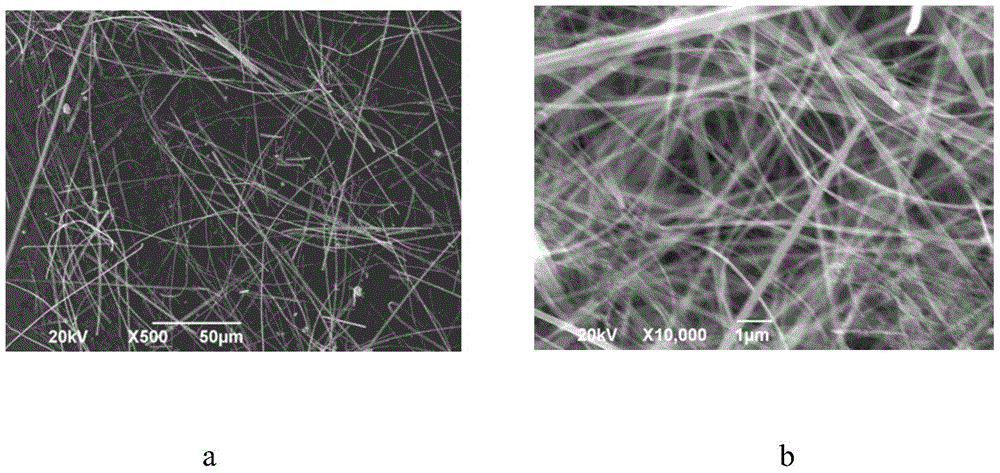

A technology of strontium doping and nanowires, which is applied in the field of preparation of LaVO3 nanowires, can solve the problems of high price, performance and application field differences, and achieve the effects of low cost, avoiding errors, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A strontium-doped LaVO 3A method for preparing nanowires, comprising the steps of:

[0030] A. Prepare 0.012mol / L ammonium metavanadate solution, lanthanum nitrate solution and 0.006mol / L strontium nitrate solution respectively, wherein the ammonium metavanadate solution needs to be heated to 50°C and stirred for 30 minutes to fully dissolve it;

[0031] B. Get 40 mL of the ammonium metavanadate solution obtained in step A, then add 32 mL of the strontium nitrate solution obtained in step A and 8 mL of the lanthanum nitrate solution obtained in step A to the ammonium metavanadate solution in sequence, stir evenly, and then use ammonia water to Adjust its pH value to 6.5, and stir for 30 minutes to obtain a mixed solution;

[0032] C. Transfer the mixed liquid obtained in step B to a 100mL hydrothermal kettle, place it in an oven, raise it from room temperature to 160°C for 30 minutes and keep it for 16 hours. After cooling down naturally, take it out and filter it, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com