Optical-fiber laser device

A technology of lasers and fiber gratings, applied in the field of lasers, can solve problems affecting the output effect of lasers, and achieve the effects of avoiding the reduction of laser efficiency, easy implementation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

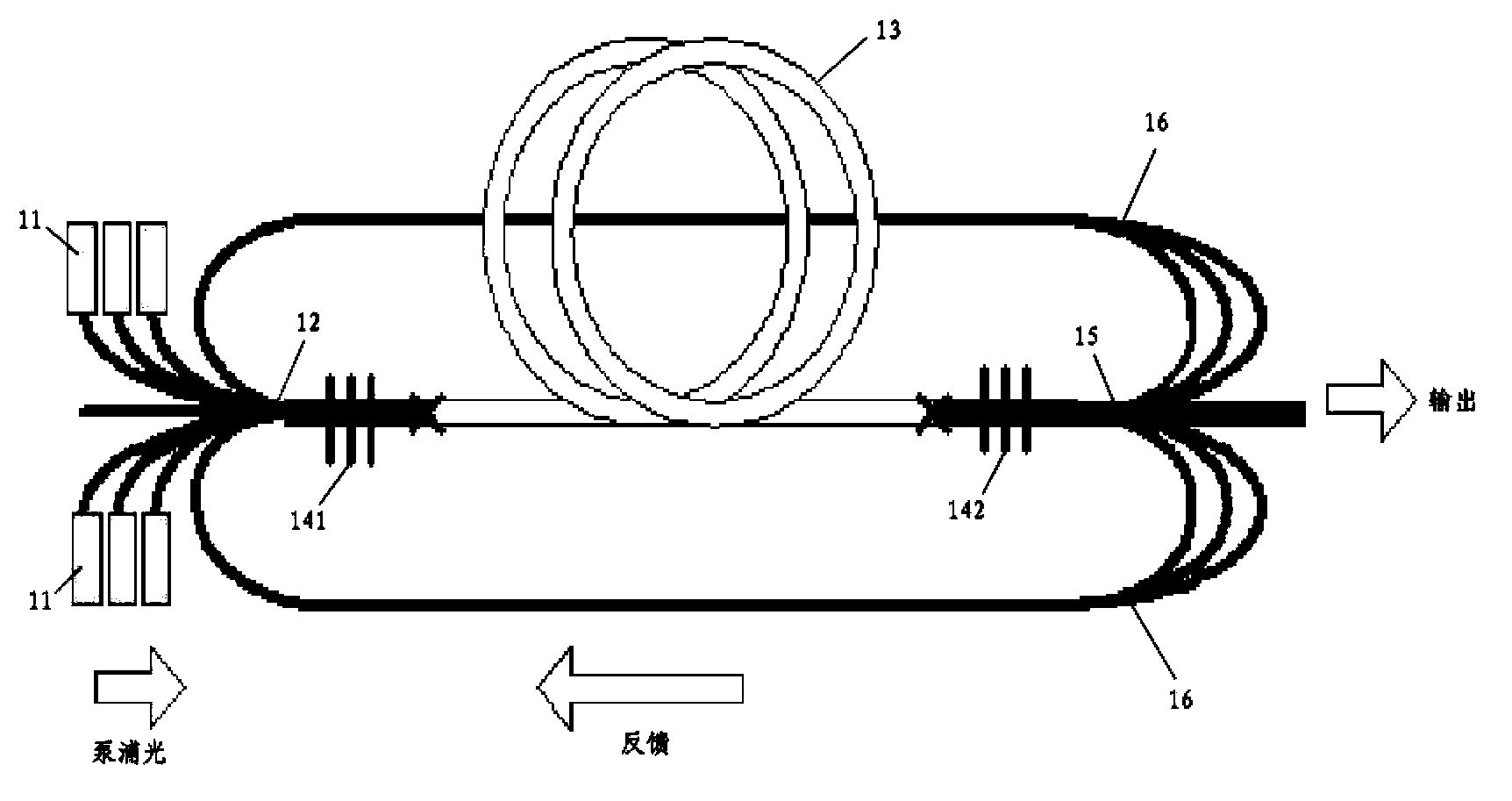

[0029] In this embodiment, the fiber laser includes: a pumping device 11, a pumping coupler, a fiber grating 14, a gain fiber 13 and a pumping feedback device, wherein:

[0030] The pump light emitted by the pump device 11 is injected into the gain fiber 13 through the pump coupler 12;

[0031] The fiber Bragg grating 14 includes a high reflection fiber Bragg grating 141 and an output fiber Bragg grating 142, and the high reflection fiber Bragg grating 141 and the output fiber Bragg grating 142 are used as cavity mirrors of the laser, and are welded to both ends of the gain fiber 13;

[0032] The length of the gain fiber 13 is shorter than the length of the fiber required to fully absorb the injected pump light, so as to ensure 10% to 50% of the residual pump light;

[0033] The pump feedback device feeds back the residual pump light at the end of the gain fiber 13 to the pump injection end, and injects it into the gain fiber 13 again.

[0034] The pump feedback device includ...

Embodiment 2

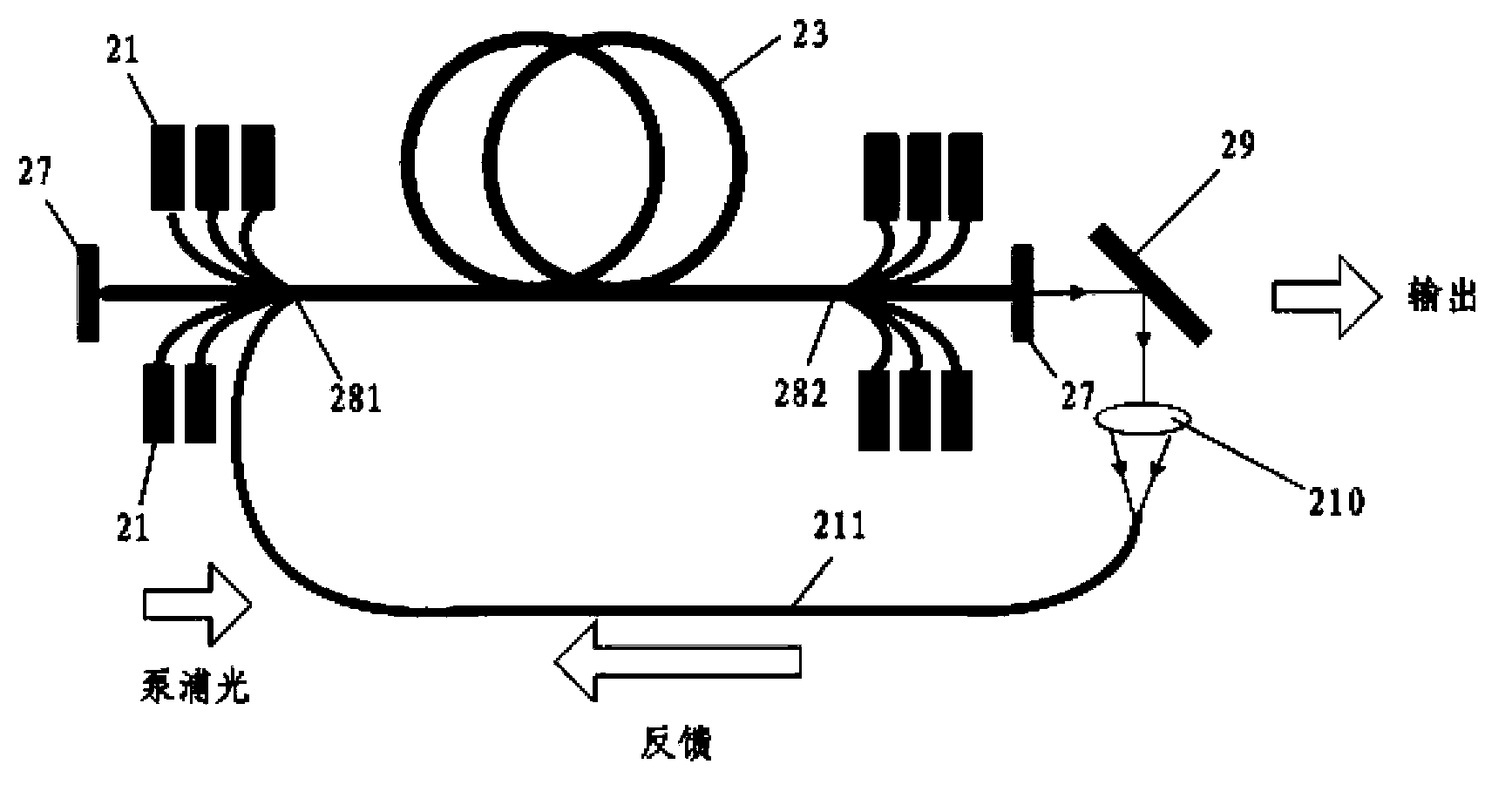

[0042] Such as figure 2 As shown, the fiber laser of this embodiment includes: a pumping device 21, a coated cavity mirror 27, a first pumping coupler 281, a second pumping coupler 282, a gain fiber 23 and a pumping feedback device, wherein:

[0043] The pump light emitted by the pump device 21 is injected into the gain fiber 23 through the first pump coupler 281 and the second pump coupler;

[0044] The coated cavity mirror 27, as a laser cavity mirror, is placed at both ends of the gain fiber 23;

[0045] The length of the gain fiber 23 is shorter than the length of the fiber required to fully absorb the injected pump light, so as to ensure 10% to 50% of the residual pump light;

[0046] The pump feedback device feeds back the residual pump light at the end of the gain fiber 23 to the pump injection end, and injects it into the gain fiber again.

[0047]The pump feedback device includes: a beam splitter 29, a coupling lens group 210 and a feedback fiber 211; after the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com