Milk replacer using cured grain raw materials to improve production performance of piglets

A technology of production performance and creep feed, applied in animal feed, animal feed, application, etc., can solve the problems of low processing efficiency and inability to carry out large-scale production, so as to improve production performance, reduce intestinal allergies, and improve feed digestion rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

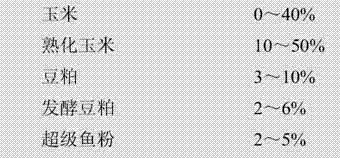

[0032] 1. Teach tank material formula:

[0033]

[0034]

[0035] Except for the ripe corn, the above-mentioned raw materials can be purchased in the raw material market.

[0036] 2. Processing method of cooked grain raw materials:

[0037] The mature corn is obtained through the following processing methods: ①The corn is passed through a three-cleaning sieve to remove impurities; ②The three-cleaned corn is lifted to the storage bin of the water-added oscillator; ③Adding water equivalent to 5% of the weight of the corn into the storage bin ; ④ Turn on the water-adding oscillator and vibrate at a frequency of 70 Hz for 30 seconds, so that the water is evenly distributed on the surface of the corn; It can heat the system, and the total time through this system is 40s. The system uses gas for infrared heating, which instantly makes the temperature inside the system reach 700°C, and the surface temperature of corn reaches 200°C; The corn is preheated to raise the corn from...

Embodiment 2

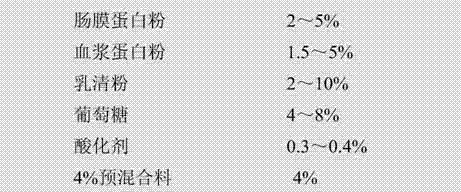

[0039] 1. Teach tank material formula:

[0040]

[0041]

[0042] Except for the ripe corn, the above-mentioned raw materials can be purchased in the raw material market.

[0043] 2. Processing method of cooked grain raw materials:

[0044] The mature corn is obtained through the following processing methods: ①The corn is passed through a three-cleaning sieve to remove impurities; ②The three-cleaned corn is lifted to the storage bin of the water-added oscillator; ③Adding water equivalent to 6% of the weight of the corn into the storage bin ; ④ Turn on the water-adding oscillator and vibrate at a frequency of 75Hz for 30s, so that the water is evenly distributed on the surface of the corn; Radiant energy heating system, the total time through this system is 50s. The system uses electricity for infrared heating, which instantly makes the temperature inside the system reach 800°C, and the surface temperature of corn can reach 225°C; in addition, the waste heat generated by...

Embodiment 3

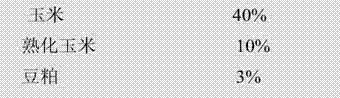

[0046] 1. Teach tank material formula:

[0047]

[0048]

[0049] Above-mentioned raw material except ripe corn, ripe soybean, other all can be bought in raw material market.

[0050] 2. Processing method of cooked grain raw materials:

[0051] The mature corn is obtained through the following processing methods: ①The corn is passed through a three-cleaning sieve to remove impurities; ②The three-cleaned corn is lifted to the storage bin of the water-added oscillator; ③Adding water equivalent to 8% of the weight of the corn into the storage bin ; ④ Turn on the water-adding oscillator, vibrate at a frequency of 80 Hz for 30 seconds, so that the water is evenly distributed on the surface of the corn; It can heat the system, and the total time through this system is 60s. The system uses biogas for infrared heating, which instantly makes the temperature inside the system reach 900°C, and the surface temperature of corn can reach 250°C; Preheat the corn to raise the corn fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com